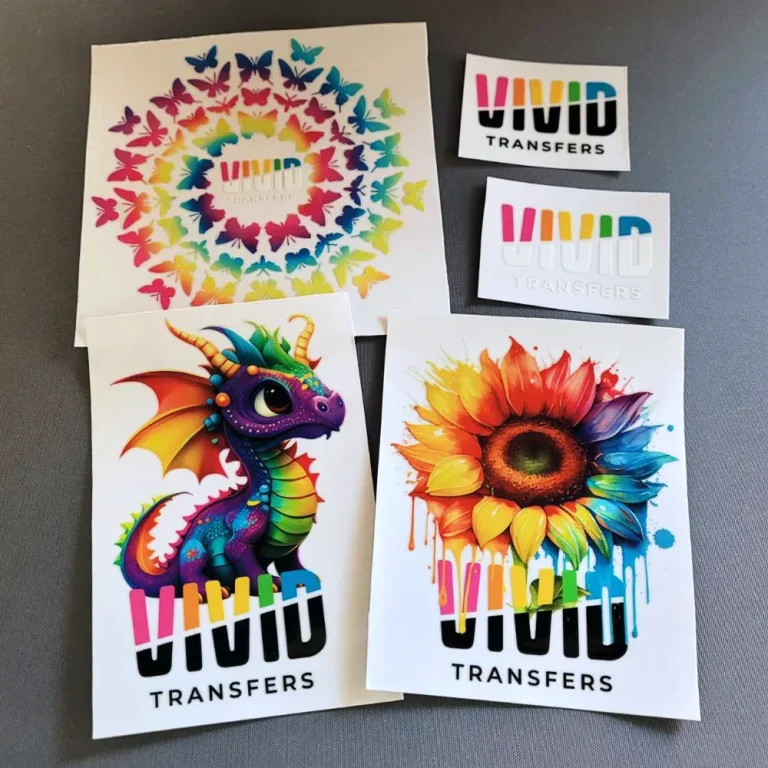

UV DTF transfers are revolutionizing the printing landscape, offering creators innovative and versatile solutions for high-quality prints. This state-of-the-art DTF printing technology utilizes ultraviolet light to cure inks on various materials, allowing for vibrant and durable designs that stand out. With its unique ability to adhere to surfaces such as fabrics, metals, and plastics, UV DTF transfers cater to a diverse range of applications—from personalized gifts to chic fashion apparel. As many industries increasingly embrace sustainable printing practices, this method emerges as an eco-friendly option, minimizing waste and chemical usage compared to traditional techniques. With a plethora of custom print options available, UV DTF transfers not only enhance artistry but also elevate brand identity in a highly competitive market.

The evolution of Direct to Film printing, particularly through UV technology, showcases a broad spectrum of creative printing solutions tailored to meet modern demands. By leveraging this innovative approach, artists and businesses can achieve intricate, high-definition images on a wide variety of surfaces. Whether you’re looking to personalize merchandise or create high-quality art prints, this versatile printing method meets the diverse needs of today’s creatives. As sustainability becomes an increasing focus in the industry, these advanced printing techniques also align with eco-friendly goals, promoting responsible manufacturing practices. Ultimately, this technology enables greater artistic expression and customization, bridging the gap between creativity and environmental consciousness.

The Evolution of Creative Printing Solutions

In the rapidly changing landscape of printing, creative solutions have become increasingly vital for businesses and artists alike. The evolution of technology has surfaced unique methods that cater to diverse needs, and UV DTF transfers stand at the forefront of this innovation. By providing a versatile option for a broad range of materials, printers are no longer confined to traditional substrates like paper and fabric. The rise of UV DTF is indicative of a larger trend where technology meets creativity, revolutionizing how artistic visions are brought to life.

Custom print options now extend beyond design; they encompass the very substrates chosen to showcase artwork. For instance, UV DTF technology allows for printing on metals, woods, and even glass, which were previously difficult or impossible to customize effectively. As a result, businesses can offer truly unique items that resonate with their target audience, leading to stronger brand identity and customer loyalty. The evolution of this technology has not only enhanced print capabilities but also encouraged businesses to think outside the box in their product offerings.

Frequently Asked Questions

What are UV DTF Transfers and how do they work?

UV DTF Transfers, or Direct to Film transfers, utilize innovative DTF printing technology that involves applying UV inks to a film. The inks are then cured using ultraviolet light, allowing for high-quality prints on various materials such as fabric, metal, and wood. This method provides exceptional detail and vibrant colors, making it a favorite among creatives.

What are the benefits of using UV DTF Transfers for custom printing solutions?

UV DTF Transfers offer numerous benefits including versatility across materials, durability, and high-quality print output. They allow creatives to produce custom print options on a range of surfaces while ensuring that prints resist fading and moisture, enhancing the longevity of the designs.

How do UV DTF Transfers compare to traditional printing methods?

Compared to traditional printing methods, UV DTF Transfers are more versatile, allowing for direct printing on diverse materials without extensive setup costs. They provide higher quality, sharper details, and minimize environmental impact due to reduced waste and chemical use, making them a sustainable printing practice.

Are UV DTF Transfers suitable for environmentally conscious brands?

Yes, UV DTF Transfers are an environmentally friendly choice, as they require fewer chemicals and less water than traditional printing methods. This sustainable printing practice appeals to brands aiming to reduce their environmental footprint while still delivering high-quality prints.

Can small businesses benefit from UV DTF Transfers for their marketing materials?

Absolutely, UV DTF Transfers are particularly cost-effective for small businesses and freelancers looking to produce marketing materials. With lower setup costs and the ability to create small production runs, this printing technology provides a flexible solution for custom print options.

What materials can be used with UV DTF Transfers?

UV DTF Transfers can be applied to a wide array of materials including fabrics, plastics, metal, glass, and wood. This versatility makes them ideal for creatives in various industries, from fashion to promotional items and everything in between.

| Key Advantages of UV DTF Transfers | |

|---|---|

| Versatility Across Materials | Suitable for printing on various surfaces like fabrics, metal, glass, and wood. |

| Durability that Lasts | Resistant to fading, scratching, and moisture, ensuring long-lasting prints. |

| High-Quality Print Output | Provides vibrant colors and sharp details, ideal for artistic designs. |

| Environmentally Friendly Choice | Lower environmental impact due to minimal chemical use and waste. |

| Cost-Effectiveness for Small Runs | Budget-friendly, especially for small to medium production runs. |

Summary

UV DTF Transfers are revolutionizing the printing landscape for creatives, providing unparalleled versatility and quality. By allowing prints on a wide variety of materials and ensuring durability with vibrant colors, this technology not only enhances artistic expression but also supports sustainable practices. As advancements continue to emerge, UV DTF Transfers promise to unlock even more innovative possibilities for artists and businesses alike.