UV DTF Transfers are transforming the landscape of modern printing, marrying the efficiency of Direct to Film techniques with the cutting-edge capabilities of UV printing. This innovative technology enables businesses to produce high-quality images that are not only visually striking but also exceptionally durable, catering to the growing demand for custom apparel and promotional items. With UV DTF’s minimal environmental impact, companies can embrace sustainable printing practices while delivering impressive print quality that stands the test of time. The versatility of UV DTF Transfers, compatible with a variety of substrates, further opens doors for creative applications across multiple industries. Investing in this state-of-the-art method positions businesses to thrive in a competitive marketplace while maximizing profitability and meeting customer expectations.

When we talk about UV DTF Transfers, we’re referring to a revolutionary printing process that employs a combination of ultraviolet technology and direct film methods. By integrating these techniques, businesses can achieve exceptional print qualities on various surfaces, making it an attractive option for manufacturers and apparel brands alike. This approach is especially appealing for those looking to implement eco-friendly solutions, as it helps reduce harmful emissions during production. The adaptability of DTF (Direct to Film) technology lends itself to numerous applications, whether it’s creating vibrant promotional items or developing custom apparel designs. As industries continuously evolve, understanding the benefits of innovative printing techniques like UV DTF will be crucial for staying competitive.

The Advantages of UV DTF Transfers

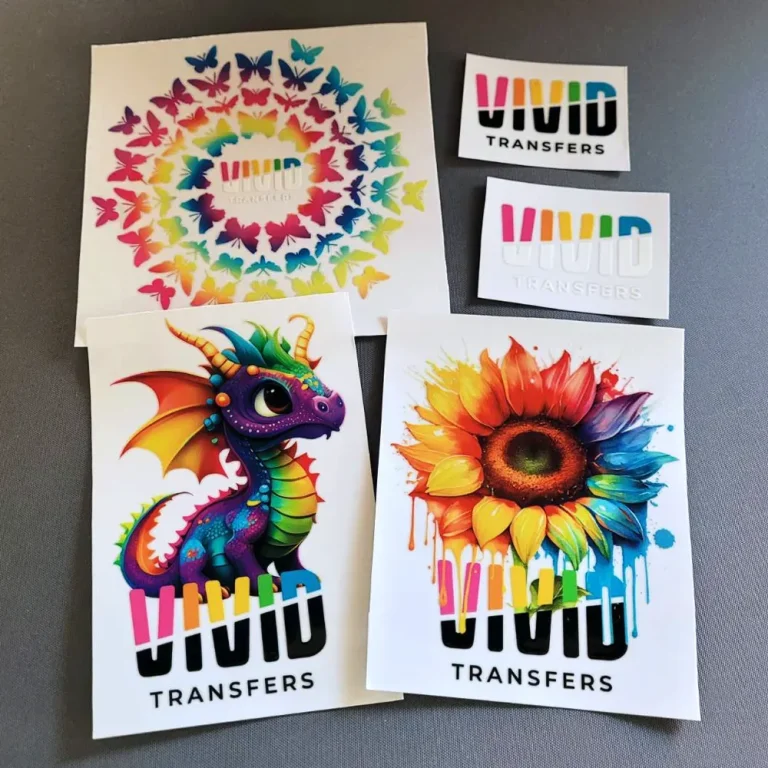

UV DTF transfers present a remarkable advancement in the printing industry, merging the efficiency of direct-to-film printing with the brilliance of UV technology. This combination allows for the production of high-quality images that are not only visually striking but also exceptionally durable. UV inks dry quickly upon exposure to UV light, resulting in a print that can withstand wear and environmental wear. The vibrancy of the colors produced through this method makes it an ideal choice for businesses looking to create visually appealing products that can attract and retain customer attention.

Another key advantage of UV DTF transfers is their ability to print on a diverse range of substrates, from traditional textiles to unique materials like metal and plastics. This versatility means businesses can explore various product lines, catering to niche markets and innovative applications. By embracing UV DTF technology, companies can enhance their service offerings, ensuring they meet a broad spectrum of customer demands while staying competitive in the market.

UV Printing: Revolutionizing Product Quality

UV printing technology is celebrated for its unmatched print quality. It enhances color depth and accuracy, resulting in captivating designs that elevate products above competitors. This aspect is crucial for businesses in sectors like custom apparel, where the visual impact significantly influences purchasing decisions. The precision achieved through UV DTF transfers allows companies to produce intricate designs that resonate with consumers, ultimately increasing sales and brand loyalty.

Moreover, UV printing significantly improves the lifespan of printed products. Unlike traditional inks, which can fade or wash out over time, UV-dried inks bond tightly to the substrate, maintaining their clarity and vibrancy even under harsh conditions. This durability can lead to increased customer satisfaction, as consumers receive products that not only look good at the point of sale but remain aesthetically pleasing long after the purchase.

Sustainable Printing Solutions with UV DTF

Sustainability has become a leading concern for businesses and consumers alike. UV DTF transfers contribute to this movement by using inks that typically emit lower levels of volatile organic compounds (VOCs) compared to traditional solvent-based inks. This makes UV DTF a more eco-friendly option, enabling companies to market themselves as environmentally conscious while still delivering high-quality products. Emphasizing these sustainable practices can attract a wider audience, particularly among environmentally aware consumers.

Additionally, the efficient printing process associated with UV DTF technology minimizes waste generated during production. The immediacy of UV curing translates to a reduction in surplus materials, allowing businesses to streamline their operations. By adopting more sustainable practices through technologies like UV DTF transfers, companies not only enhance their profitability but also align themselves with the values of modern consumers who prioritize eco-friendly products.

Cost-Effectiveness of UV DTF Transfers

When assessing the cost-effectiveness of adopting UV DTF transfers, it’s essential to look beyond initial investment costs. Although the transition may require a financial commitment, the long-term savings are substantial. Reduced material waste is a significant factor; accurate prints diminish the need for reworks, lower labor costs from automation enhance efficiency, and the longevity of products minimizes repeat sales.

Moreover, businesses can optimize their production processes. The quick curing times associated with UV printing allow for faster turnaround on orders, improving overall productivity. By maximizing output without sacrificing quality, companies can foster increased profitability. The initial costs of transitioning to UV DTF technology can be recovered quickly through these operational efficiencies, making it a valuable investment for future growth.

Emerging Trends in Custom Apparel

The landscape of custom apparel is rapidly evolving, with trends pivoting towards individualized, high-quality products. Companies that leverage UV DTF transfers can capitalize on this shift by offering bespoke designs that appeal to fashion-forward consumers. This technology enables intricate designs and the use of vibrant colors, making it an ideal fit for custom apparel that stands out in a saturated market.

Furthermore, as personalization continues to be a driving force in consumer purchases, businesses equipped with UV DTF printing capabilities are well-positioned to fulfill this demand. By allowing customers to customize their apparel items, companies can enhance customer engagement and satisfaction. The ability to produce unique, high-quality products quickly positions them at the forefront of custom apparel trends, increasing market share and brand loyalty.

Future-Proofing Your Printing Business

In a fast-paced printing industry, future-proofing operations is essential for survival and growth. Businesses can enhance their resilience by adopting innovative technologies like UV DTF transfers. As market demands shift, having a flexible printing solution allows companies to pivot quickly, meeting new consumer needs without incurring excessive costs or delays.

Additionally, the integration of UV DTF technology prepares businesses for advancements in printing technology. As the industry evolves, companies that invest in modern solutions will find themselves better equipped to adopt further innovations. By staying ahead of market trends and consumer preferences, businesses can ensure their relevance in the printing space, ultimately maximizing profits and securing long-term success.

Frequently Asked Questions

What are UV DTF transfers and how do they differ from traditional printing methods?

UV DTF (Direct to Film) transfers utilize UV printing technology to create high-quality graphics on various substrates. Unlike traditional printing that relies on solvent or water-based inks, UV DTF uses UV-curable inks that dry instantly when exposed to UV light. This results in vibrant colors, excellent durability, and the ability to print on diverse materials, making UVDTF a superior choice for custom apparel and promotional products.

How does UV DTF printing enhance print quality compared to other methods?

UV DTF transfers leverage advanced UV printing techniques that produce sharp, vivid images with exceptional detail. The inks used in UV DTF are cured through UV light, allowing for greater adhesion to materials and resistance to fading or scratching. This superior print quality is ideal for creating durable products, ensuring customer satisfaction and repeat business.

What substrates can be used with UV DTF transfers?

One of the key benefits of UV DTF transfers is their versatility. They can print on a wide range of substrates including textiles, metals, plastics, and more. This flexibility allows businesses to cater to various markets, from custom apparel to packaging solutions, significantly enhancing their product offerings and potential customer base.

Are UV DTF transfers environmentally friendly?

Yes, UV DTF transfers are considered more environmentally sustainable compared to traditional printing methods. The UV inks used contain fewer volatile organic compounds (VOCs), reducing harmful emissions and making them a greener choice for businesses. By adopting UV DTF technology, companies can also market their products as eco-conscious, appealing to environmentally aware consumers.

What are the long-term cost benefits of investing in UV DTF printing?

While the initial investment in UV DTF technology may be higher than traditional printing methods, it offers long-term cost savings. UV DTF printing reduces material waste and labor costs due to its efficiency and automation capabilities. The high-quality output minimizes the need for reprints, resulting in improved profit margins and operational efficiencies over time.

How can businesses capitalize on market trends with UV DTF transfers?

The demand for UV DTF printing technology is rapidly growing across various sectors, including custom apparel and promotional products. By integrating UV DTF solutions into their operations, businesses can meet modern consumer demands and tap into expanding markets. This adaptability not only helps companies stay competitive but also fosters profitability in a dynamic printing industry.

| Key Points | Description |

|---|---|

| High Quality and Durability | UV DTF transfers ensure vibrant colors and excellent adhesion, enhancing the longevity of prints against wear and fading. |

| Versatile Substrate Compatibility | Compatible with a variety of materials, allowing businesses to diversify their product offerings and reach new markets. |

| Long-Term Cost Effectiveness | Reduces material waste and lowers labor costs, making it a financially sound investment over time. |

| Environmentally Friendly Practices | Uses UV inks with fewer VOCs, contributing to sustainability and appealing to eco-conscious consumers. |

| Capitalizing on Market Trends | Addresses the growing demand for custom printing solutions in various sectors, enhancing competitiveness. |

| Expert Insights and Testimonials | Industry leaders endorse UV DTF technology for its transformative potential in improving operational efficiencies. |

Summary

UV DTF Transfers represent a groundbreaking advancement in the printing industry, offering businesses a pathway to enhance their operational capabilities and profit margins. By delivering exceptional print quality, broad substrate compatibility, and sustainable practices, UV DTF technology stands out as a strategic investment. Leveraging these attributes not only elevates product offerings but also significantly reduces operational costs over time. Companies embracing this innovative solution position themselves effectively to seize emerging market opportunities, ensuring they remain competitive in an evolving landscape. Overall, investing in UV DTF Transfers is not just a choice; it’s a trajectory towards sustained growth and improved profitability.