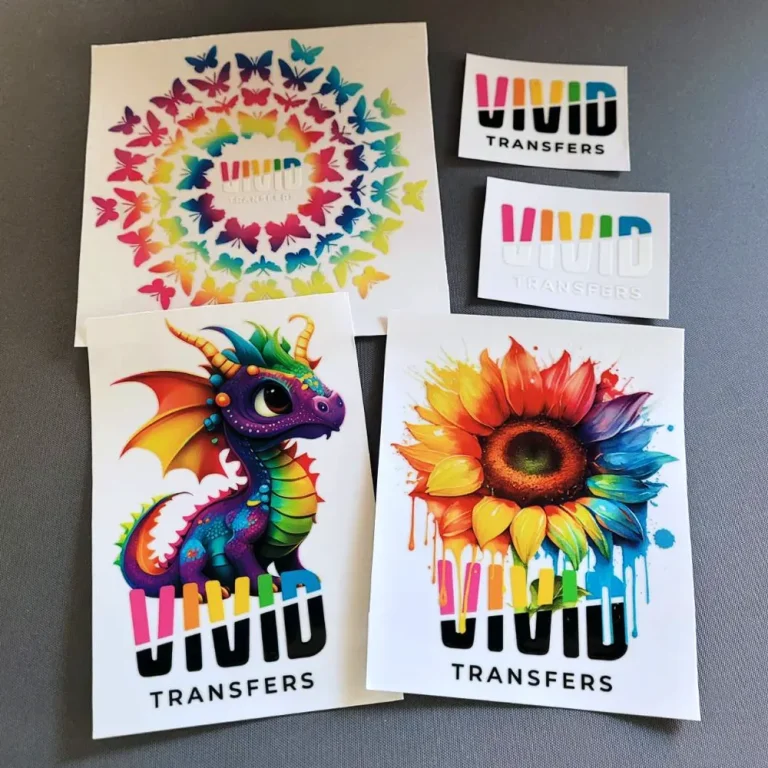

In today’s vibrant printing landscape, UV DTF transfers have revolutionized the way stunning designs are created, enabling artists and businesses to push the boundaries of creativity. This innovative method combines the precision of UV printing with the versatility of Direct to Film (DTF) applications, allowing for remarkable custom prints on various materials. With its ability to produce vibrant colors and intricate patterns, UV DTF transfers are increasingly becoming a favorite among designers seeking high-quality results. As you learn how to create UV DTF transfers, you’ll discover a world of possibilities where creativity knows no bounds. This guide will navigate you through the essential steps to master the art of design with DTF technology, ensuring your prints stand out in today’s competitive market.

Often referred to as UV Direct to Film transfers, this groundbreaking printing technique merges the capabilities of ultraviolet printing with seamless film applications. By harnessing the power of heat transfer printing, designers can produce incredibly detailed and durable designs across a wide range of surfaces, from textiles to hard substrates. The flexibility of using either custom prints or pre-designed templates empowers creators to generate eye-catching graphics that can elevate their branding or personal projects. Utilizing the best practices for design with DTF, you can achieve stunning visual effects that captivate audiences and enhance product offerings. As we delve into the specifics, you’ll gain insight into the intricacies of working effectively with this cutting-edge technology.

Understanding UV DTF Transfers and Their Benefits

UV DTF transfers are a cutting-edge printing solution that marries the benefits of UV printing technology with the simplicity of DTF application. This innovation allows for high-quality, vibrant prints on various substrates, such as fabrics, wood, and plastic. Users are drawn to this method not only because of the exceptional color quality but also due to the durability of the prints, which can withstand wear and tear. By utilizing advanced resin-based inks that cure instantly under UV light, designs maintain their vibrancy over time, making them ideal for custom apparel and promotional products.

One of the most significant advantages of UV DTF transfers is their versatility. Artists and businesses can create intricate designs that incorporate multiple colors and textures, enabling a unique look for each project. Additionally, the heat transfer process ensures that the design adheres effectively to the material, resulting in a smooth finish and long-lasting appearance. This adaptability makes UV DTF transfers a favorite among designers seeking to push the boundaries of traditional printing methods.

Frequently Asked Questions

How to create UV DTF transfers effectively?

To create UV DTF transfers effectively, start with high-resolution designs using graphic software like Adobe Illustrator or Photoshop. Print your design using a compatible UV printer on DTF film, ensuring proper application of DTF powder for adhesion. Finally, apply heat through a heat press to transfer your design onto the substrate, followed by a cooling and a second curing cycle for durability.

What is the process of UV printing in UV DTF transfers?

The process of UV printing in UV DTF transfers involves using ultraviolet light to cure and dry the ink instantly. This technique allows for vibrant color application on DTF film, enabling intricate designs to be printed quickly and efficiently, which can then be transferred onto various surfaces with heat.

Can you design with DTF for custom prints using UV technology?

Yes, designing with DTF for custom prints using UV technology is highly effective. By leveraging vector graphics and high DPI images, you can create stunning designs that will translate beautifully when transferred via UV DTF methods, ensuring high-quality custom prints on various materials.

What are the advantages of UV DTF transfers over traditional heat transfer printing?

UV DTF transfers offer several advantages over traditional heat transfer printing, including superior durability, vibrant color vibrancy, and the ability to print on a wider variety of substrates. Additionally, UV DTF technology allows for finer detail and intricate designs without compromising quality.

What settings should I use for heat transfer printing with UV DTF?

For heat transfer printing with UV DTF, set your heat press to approximately 160°C (320°F) for 10 to 15 seconds. It’s essential to adjust pressure settings based on the substrate thickness to ensure optimal adhesion, which enhances the final quality of your prints.

How do you ensure the longevity of UV DTF transfers?

To ensure the longevity of UV DTF transfers, perform a second curing cycle after peeling the film to reinforce the design’s adhesion. Additionally, use high-quality DTF films and UV inks while ensuring compatibility with your substrates to improve durability and maintain vibrant colors.

| Key Point | Description |

|---|---|

| Introduction | UV DTF transfers combine UV printing and DTF techniques to create vibrant prints on various surfaces. |

| Process Overview | A step-by-step guide consists of design creation, film preparation, powder application, heat curing, peeling, and final curing. |

| Design Creation | Use high-resolution vector graphics with professional software for optimal results. |

| Film Selection | Choose compatible DTF film and a suitable UV printer that handles white ink for dark surfaces. |

| Heat Application | Set the heat press to 160°C (320°F) for 10-15 seconds with proper pressure. |

| Recent Trends | Increased demand for custom prints and a focus on sustainability in materials. |

| Resources | Check out Printwear, Impressions, and T-Shirt Magazine for further insights on UV DTF technology. |

Summary

UV DTF transfers have revolutionized the way designs are created and applied, allowing for an exceptional level of detail and vibrancy that traditional methods simply cannot achieve. This innovative technology combines the efficiency of Direct to Film printing with the reliability of UV curing, resulting in stunning, durable prints on a variety of surfaces, from textiles to hard substrates. As you master the step-by-step processes involved, such as using suitable design software, preparing the film, and expertly applying heat, you will unlock endless possibilities for creative expression. Furthermore, staying updated on industry trends like customization and sustainability will keep your designs relevant and appealing to modern consumers. Dive into the world of UV DTF transfers and unleash your creativity today!