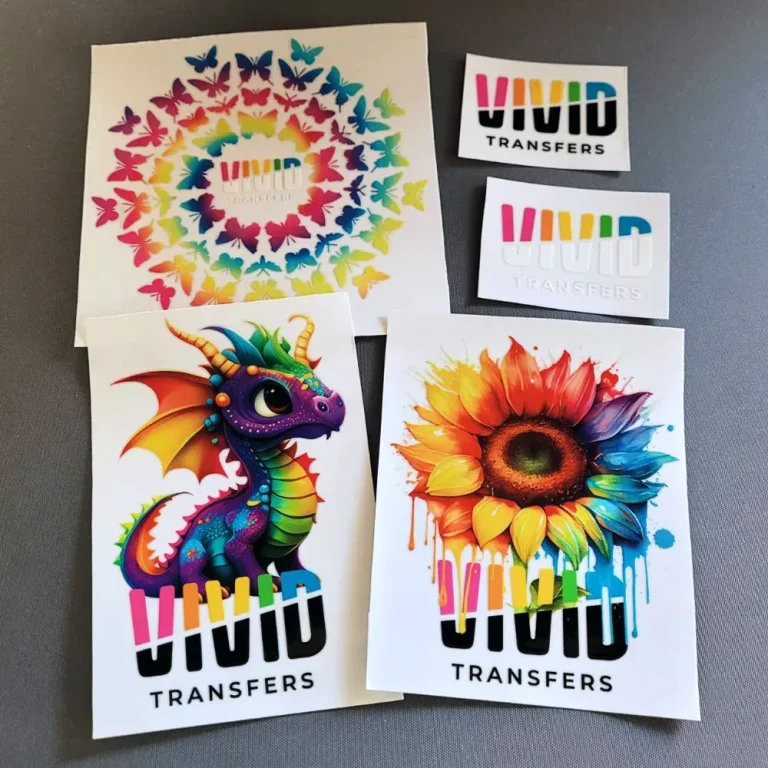

UV DTF transfers are transforming the landscape of customizable printing solutions, seamlessly blending UV printing technology with direct-to-film methods. This innovative hybrid technology allows for vibrant, durable graphics that adhere to a wide array of substrates, making it a game-changer in apparel printing technology. As the demand for personalized products continues to escalate, UV DTF transfers provide an efficient way to meet market needs while maintaining high-quality standards. Not only do these transfers reduce waste through their sustainable printing practices, but they also minimize the use of harmful chemicals, appealing to environmentally conscious consumers. This article will delve deeper into the mechanics, applications, and best practices for leveraging UV DTF technology effectively in your business.

Often referred to as UV Direct to Film transfers, this advanced printing technique leverages ultraviolet light to cure inks directly onto a specially designed film. By integrating the benefits of direct-to-film methods with the efficiency of UV printing, this technology produces striking designs that are exceptionally durable. The versatility of UV DTF transfers allows for a broad spectrum of applications, ranging from apparel to promotional materials, thereby catering to diverse market demands. With rising consumer interest in customized products, adopting this innovative technology positions businesses favorably in a competitive landscape. Furthermore, the sustainable nature of UV printing not only enhances product quality but also aligns with the growing trend towards eco-friendly practices in the printing industry.

Understanding the Advantages of UV DTF Transfers

UV DTF transfers combine cutting-edge technology with practical benefits that have transformed the printing landscape. One of the primary advantages is the exceptional durability offered by UV inks, which have superior scratch resistance and adhesion properties. This means that products adorned with UV DTF transfers can withstand daily wear and tear without losing their vibrancy or integrity. Furthermore, the instant curing process of UV printing technology allows for rapid production times, eliminating long drying periods and making this method ideal for businesses looking to streamline their production workflow.

Another noteworthy advantage of UV DTF transfers is their environmental impact. As sustainable printing solutions gain traction, this technology stands out by minimizing waste and eliminating the need for harmful solvents. The precision of UV printing ensures that less material is wasted during production, aligning perfectly with the growing demand for eco-friendly practices in the printing and apparel industries. Companies adopting UV DTF technology can meet consumer expectations for sustainability while benefiting from efficient, high-quality production.

The Process of Printing with UV DTF Technology

The printing process with UV DTF technology integrates several key steps that ensure high-quality results. Initially, a digital design is created based on customer specifications, which allows for customized printing solutions tailored to specific products. Once the design is ready, it is printed onto the specially coated transfer film using a UV printer. During this phase, the UV inks are applied in vibrant colors that stand out on various substrates, ensuring that the final product meets clients’ aesthetic needs.

After printing, the film undergoes a curing process where the UV light instantly hardens the inks, rendering them ready for application immediately. This quick turnaround is particularly beneficial for businesses focusing on rapid order fulfillment. Following curing, the transfer is applied to the desired substrate—whether it be apparel or promotional merchandise—using heat and pressure. This technique guarantees that the transfer maintains the design’s sharpness and color fidelity throughout its lifespan, making UV DTF an attractive option for both manufacturers and consumers.

Exploring Versatile Applications of UV DTF Transfers

One of the most impressive features of UV DTF transfers is their versatility, allowing them to be applied to a broad spectrum of materials beyond just textiles. Businesses can utilize this technology for home decor items, such as custom ceramic tiles or decorative wooden products, expanding their offerings and tapping into niche markets. This adaptability not only enhances a company’s product portfolio but also attracts a diverse customer base looking for unique and personalized items.

Moreover, UV DTF transfers find practical use in promotional merchandise, allowing for the creation of personalized mugs, tote bags, and more that can effectively promote brand identity. The durability of products created through this method ensures longevity, providing clients with cost-effective and appealing advertising solutions. By embracing the versatility of UV DTF technology, companies can remain competitive and meet the evolving demands of their consumers, making it a critical asset in modern printing practices.

Harnessing UV Printing Technology for Customization

UV printing technology empowers businesses to offer unparalleled customization capabilities to their clients. With the rise of consumer preferences for personalized products, UV DTF transfers enable companies to cater to this demand by easily producing custom designs on-demand. This technology allows for intricate details and vibrant colors in the graphics, ensuring that each item delivers a unique touch that resonates with individual tastes.

Additionally, the flexibility of UV DTF transfers means that businesses can quickly adapt to changing trends and preferences. As markets evolve, companies can adjust their design offerings in real-time, creating a responsive manufacturing environment that keeps pace with consumer needs. This level of customization is essential for businesses looking to enhance customer engagement and loyalty, making UV printing technology a pivotal component in successful marketing strategies.

Best Practices for Maximizing UV DTF Efficiency

To unlock the full potential of UV DTF technology, businesses must adhere to best practices that enhance efficiency and output quality. One critical practice is proper surface preparation, which involves thoroughly cleaning substrates to ensure optimal adhesion of the transfer. Any residue or contaminants can compromise the integrity of the design, leading to poor results. By implementing rigorous surface cleaning protocols, companies can improve the durability and longevity of their UV DTF products.

Moreover, calibrating printer settings to align with specific materials is imperative for achieving successful transfer applications. By adjusting factors such as exposure time and temperature, operators can maximize ink adhesion and eliminate issues such as peeling or fading over time. Regular testing and experimentation with different materials also play a significant role in optimizing production quality, allowing businesses to refine their processes and deliver superior products to their customers.

Navigating Challenges Associated with UV DTF Technology

Despite its many advantages, UV DTF technology does come with certain challenges that businesses must navigate. Initial equipment costs can be a significant barrier for smaller companies or startups looking to adopt this innovative printing solution. These costs, encompassing both the printer and necessary materials, require careful consideration and planning during budgeting to ensure financial viability.

Additionally, the technological complexity associated with UV DTF machines necessitates operator training and skill development. Investing in comprehensive training programs is crucial to equip personnel with the necessary skills to operate machines efficiently and produce high-quality outputs consistently. Over time, as training programs solidify, businesses can expect to see a decrease in errors and a significant improvement in overall production quality.

Frequently Asked Questions

What are the advantages of using UV DTF transfers in apparel printing technology?

UV DTF transfers offer several advantages in apparel printing technology, including remarkable durability, vibrant color reproduction, and superior adhesion to a variety of substrates. This hybrid process combines the benefits of UV printing with the versatility of Direct to Film methods, making it suitable for customized printing solutions on textiles and beyond.

How does the UV printing technology in UV DTF transfers enhance print quality?

UV printing technology enhances print quality in UV DTF transfers by using ultraviolet cured inks that instantly solidify upon exposure to UV light. This results in high-resolution graphics with sharp details and vibrant colors that are resistant to scratches and fading, which is crucial for producing long-lasting customized products.

Can UV DTF transfers be used on substrates other than textiles?

Yes, UV DTF transfers are highly versatile and can be used on various substrates beyond textiles, including ceramics, wood, glass, and metals. This capability allows businesses to expand their offerings and explore diverse markets through sustainable printing practices.

What challenges might businesses face when adopting UV DTF transfers?

Businesses may encounter several challenges when adopting UV DTF transfers, such as high initial equipment costs, the need for skilled operators, and material compatibility issues. Overcoming these challenges often involves thorough testing and calibration to ensure optimal results.

In what ways does UV DTF technology support sustainable printing practices?

UV DTF technology supports sustainable printing practices by producing less waste compared to traditional methods. It minimizes overspray and eliminates the need for additional solvents, contributing to a more environmentally friendly production process while still delivering high-quality customized printing solutions.

What are the best practices for effectively using UV DTF transfers?

Best practices for effectively using UV DTF transfers include ensuring proper surface preparation of substrates, calibrating printer settings according to material needs, and conducting thorough testing of materials and inks. These steps help optimize adhesion, durability, and print quality for successful application.

| Key Points | Details |

|---|---|

| Definition | UV DTF transfers use UV cured inks on a transfer film, offering durability and vibrant colors. |

| Technology | Digital designs are printed and instantly cured, allowing immediate transfer application. |

| Market Trends | Growing demand for customizable products and sustainable practices. |

| Applications | Versatile uses include textiles, home decor, promotional merchandise, and industrial applications. |

| Best Practices | Surface preparation, printer calibration, and thorough testing are essential for success. |

| Challenges | High initial costs, need for operator training, and material compatibility issues. |

Summary

UV DTF Transfers are transforming the printing landscape with their innovative blend of technology and versatility. This breakthrough method enables businesses to produce customizable, high-quality graphics with impressive durability on a variety of substrates. As consumer preferences lean towards personalization and sustainability, UV DTF Transfers cater perfectly to these trends, allowing companies to efficiently deliver unique products that stand out. With the capability to adapt to different industries, from textiles to industrial applications and promotional items, UV DTF Transfers are not just a modern advancement; they represent the future of printing technology. Whether you’re in apparel production or creating unique merchandise, embracing UV DTF Transfers ensures you stay at the forefront of industry developments.