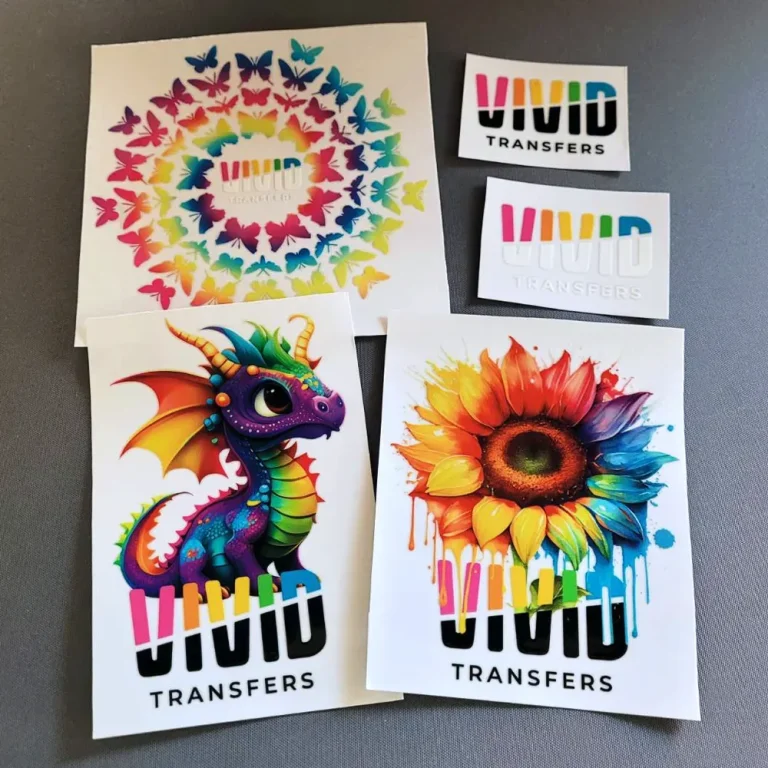

In the dynamic realm of custom printing technology, **UV DTF Transfers** have emerged as a game-changer for artists and designers looking to enhance their artwork with vibrant and durable prints. This innovative method combines the best of UV printing and DTF techniques, leading to stunning visuals that stand the test of time. As the demand for high-quality prints increases, understanding the advantages of UV DTF transfers becomes essential for anyone in the creative field. In this guide, we’ll explore best practices for UV DTF, uncover artwork enhancements specifically tailored for this technology, and share insights into how to successfully implement UV DTF printing in your projects. Join us as we dive into the exciting world of UV DTF transfers and discover how they can elevate your artistic expressions.

UV DTF printing, or Direct to Film printing with ultraviolet curing, represents a revolutionary advancement in the printing industry that enhances artists’ ability to produce exceptional artwork. Often referred to as a seamless fusion of DTF and UV technologies, this method allows for the creation of intricate designs on a variety of surfaces, promising both resilience and vividness. As designers strive for the highest quality in their projects, understanding the nuances of this custom printing technology is crucial. This discussion will outline key strategies for maximizing the use of UV DTF transfers and delve into their myriad advantages, transforming the approach to modern printing. Explore with us how this innovative method can help redefine your artistic capabilities.

Understanding the Mechanics of UV DTF Transfers

UV DTF (Direct to Film) Transfers are at the forefront of modern printing technology, combining precision and flexibility for artists and designers. This innovative process begins with high-quality UV printing, where ultraviolet light instantly cures the inks, ensuring vibrant colors and superior durability. By utilizing DTF methods, creators can apply intricate designs onto films, which are then heat-transferred onto various substrates. This blended technique not only enhances the visual appeal but also guarantees adhesion and protection against wear and tear.

The mechanics of UV DTF revolve around its dual capabilities: the immediate curing of UV inks and the versatility of DTF applications. The use of heat and pressure during the transfer process solidifies the image onto diverse surfaces, from textiles to metals. This opens a vast array of possibilities for artistic expression, fulfilling the demands of commercial printing sectors and personalized projects alike. Understanding these mechanics is crucial for artists aiming to leverage UV DTF technology effectively.

Frequently Asked Questions

What are the key features of UV DTF transfers in printing?

UV DTF transfers combine the durability of UV printing with the flexibility of DTF methods, resulting in vibrant, high-quality prints. This technology uses ultraviolet light to cure inks instantly, allowing for rich colors and long-lasting images that adhere well to various surfaces, such as textiles, wood, glass, and metal.

How do I ensure the best results with UV DTF printing?

To achieve optimal results with UV DTF printing, follow best practices such as thorough surface preparation, maintaining consistent temperature during the application process, using high-quality UV DTF inks, and ensuring an even curing process with UV light. These steps help improve adhesion and print durability.

What are the advantages of using UV DTF transfers over traditional printing methods?

The advantages of UV DTF transfers include greater durability due to UV curing, versatility across different substrates, and the capability to produce vivid colors, even on dark materials with the use of white ink. This makes UV DTF an excellent choice for artists looking for innovative custom printing technology.

Can UV DTF transfers be used on various materials?

Yes, UV DTF transfers are exceptionally versatile and can be applied to a wide range of materials including textiles, wood, glass, metal, and more. This adaptability allows artists to explore multiple media and enhance their artwork creatively.

What should I consider when preparing artwork for UV DTF transfers?

When preparing artwork for UV DTF transfers, ensure your designs are high-resolution and suitable for the UV printing process. Consider enhancements such as adding vibrant colors, appropriate contrasts, and using white ink for prints on darker substrates to achieve the best visual impact.

What trends are emerging in the UV DTF transfer market?

Emerging trends in UV DTF transfers include increasing accessibility for smaller businesses due to technological advancements and decreasing production costs. This growth is spurring creativity in custom apparel and promotional products, allowing artists and designers to cater to diverse consumer preferences.

| Key Point | Description |

|---|---|

| What are UV DTF Transfers? | Revolutionary printing technology combining UV and DTF methods for vibrant, durable prints. |

| Advantages of UV DTF Transfers | 1. Durability: Resistant to scratches, moisture, and UV light. 2. Versatility: Applicable to various surfaces like textiles and metal. 3. Vivid Colors: Produces bright images, working especially well on dark materials. |

| Best Practices | 1. Surface Preparation: Clean the substrate thoroughly. 2. Temperature Control: Maintain consistent temperatures during application. 3. Quality Ink: Use high-quality inks for better results. 4. Curing Process: Ensure uniform UV light distribution during curing. |

| Market Trends | Rising demand in custom apparel and promotional products, with increased accessibility for small businesses existing in the market. |

| Conclusion | UV DTF transfers empower artists to enhance their artwork by ensuring quality and vibrant prints, leading to more creative possibilities in the market. |

Summary

UV DTF Transfers are an innovative printing solution that allows artists and designers to elevate their artwork, combining durability and vibrance in each print. This technology enables a broad range of applications on various surfaces, making it highly versatile for creative expression. The benefits of UV DTF include enhanced durability against environmental factors, a stunning color palette, and the ability to produce high-quality prints on diverse materials. By following best practices, such as proper surface preparation and using quality inks, creators can maximize the potential of UV DTF transfers. With the growing trend of adoption in various sectors, now is the optimum moment for artists to embrace UV DTF transfers to transform their creative visions into reality.