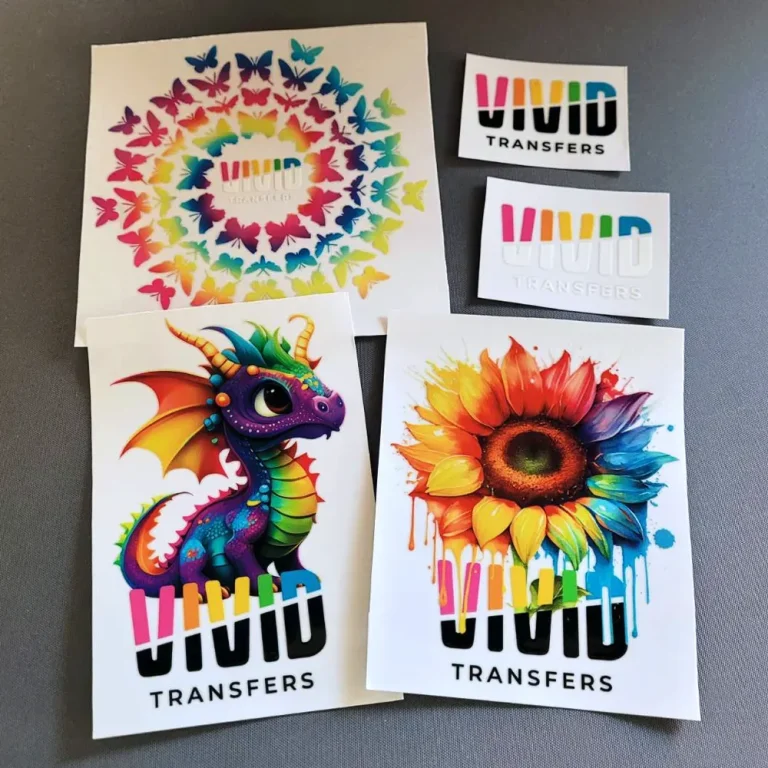

In the dynamic realm of custom printing, **UV DTF transfers** stand out as a revolutionary method for achieving stunning, durable designs. By using UV inks to print on specialized transfer films, this technique ensures vibrant colors that can be applied to a variety of surfaces, including textiles and plastics. The versatility of UV DTF printing allows for the seamless integration of personalized designs into everyday items, making it a popular choice among businesses and hobbyists alike. With the right equipment—such as a heat press machine and UV printer—users can unlock new creative possibilities, crafting unique products that truly resonate with their audience. As the demand for custom solutions continues to rise, understanding the intricacies of UV DTF transfers becomes essential for anyone looking to capitalize on this exciting market.

Also known as Direct to Film UV printing, this innovative technique employs a specialized form of transfer film to apply designs created with UV inks onto various substrates. Utilizing a heat press machine, the process merges imaging technology with durable materials to produce lasting and eye-catching results. With applications ranging from personalized clothing to bespoke home decor, DTF prints have quickly gained traction for their high-quality outputs and versatility. This method not only allows for the production of detailed graphics but also caters to the ever-growing demand for customization in various industries. As the technology evolves, those interested in tapping into the world of DTF transfers continue to explore creative ways to bring their ideas to life.

Understanding UV DTF Transfers

UV DTF (Direct to Film) transfers represent a revolutionary technique in the custom printing industry. This method involves using a specialized UV printer to apply vibrant inks onto a transfer film. The incredible versatility of UV DTF allows printers to successfully transfer these vivid designs onto various substrates including textiles, plastics, and even wood. By utilizing cutting-edge UV inks, the prints produced are not only striking in terms of color but also exhibit exceptional durability, making them ideal for both indoor and outdoor applications.

In essence, the process begins with printing on a specific type of transfer film designed to work optimally with UV inks. Once the design is printed, it undergoes a heat press application, transferring the ink to the chosen substrate. This technique is particularly favored for its ability to produce long-lasting prints with impressive color fidelity, allowing businesses and individual creators to meet the growing demand for customized products.

Frequently Asked Questions

What is the process of UV DTF transfers and how does it work?

UV DTF transfers involve printing a design onto a special transfer film using UV inks. The printed film is then transferred onto various substrates like textiles, plastics, or wood with the help of a heat press machine. This method ensures vibrant colors and durability, making it popular among custom printers.

What type of UV printer is best for UV DTF transfers?

For UV DTF transfers, a high-quality UV printer such as those from Mimaki, Roland, or Epson is ideal. These printers use UV-cured inks to produce clear and consistent prints, which are crucial for achieving professional results.

Why is transfer film important in UV DTF transfers?

The choice of transfer film is critical in UV DTF transfers because specific UV DTF transfer films are designed to absorb UV inks effectively. This enhances print quality and ensures better adhesion to the substrate, resulting in long-lasting designs.

How does a heat press machine function in the UV DTF transfer process?

A heat press machine applies controlled heat and pressure to the transfer film and substrate, ensuring that the UV inks adhere properly. Proper settings are crucial to achieve durable and vibrant prints, making the heat press a vital piece of equipment in the UV DTF transfer process.

What role does a curing unit play in UV DTF transfers?

A curing unit with UV lamps is essential in the UV DTF transfer process as it fully sets the UV inks, enhancing their durability. Curing prevents fading and ensures that prints are suitable for both indoor and outdoor use, making it a key component for high-quality outcomes.

What are the latest trends in UV DTF transfers?

The demand for UV DTF transfers has surged due to the popularity of personalized products across various markets, including fashion and home decor. Recent innovations in ink formulations and printing technology aim to improve durability and color fidelity, positioning UV DTF transfers as a leading choice for custom printing.

| Key Points | Description |

|---|---|

| What is UV DTF Transfer? | A technique that uses UV inks printed on a film that is then transferred to various substrates using heat and pressure. |

| Equipment Needed | – **UV Printer**: Essential for printing high-quality designs. – **Transfer Film**: Special film that absorbs UV inks for successful transfer. – **Heat Press Machine**: Vital for applying heat and pressure to adhere prints. – **Curing Unit**: Receives prints with UV lamps to set and ensure durability of inks. |

| Techniques for Success | – **Pre-Treatment**: To improve adhesion on different substrates. – **Print Settings**: Optimizing settings results in better color and quality. – **Pressing Techniques**: Monitoring heat and pressure prevents damage while ensuring good adhesion. |

| Innovations & Trends | New advancements in technology enhance durability, color fidelity, and speed of the process. Rising demand for personalized products increases the market trend for UV DTF transfers. |

| Further Learning Resources | – **Printful Blog**: Guide for beginners. – **Impressions Magazine**: Articles on techniques and practices. – **YouTube**: Tutorials on equipment setup and application techniques. |

Summary

UV DTF Transfers have revolutionized the custom printing industry by providing unparalleled versatility in creating vibrant and long-lasting designs. These transfers, utilizing UV inks, enable printing on various substrates, allowing for a wide range of personalized products. The essential equipment includes a quality UV printer, specific transfer films, a heat press machine, and a curing unit, all pivotal in the transfer process. Successful printing hinges on employing proper techniques, including pre-treatment and careful adjustments of print settings. As the technology evolves, the increasing demand for tailored products ensures that UV DTF Transfers remain at the forefront of personalized printing solutions. In summary, embracing the tools and techniques of UV DTF transfers offers creators an exciting avenue to express their creativity and meet consumer desires.