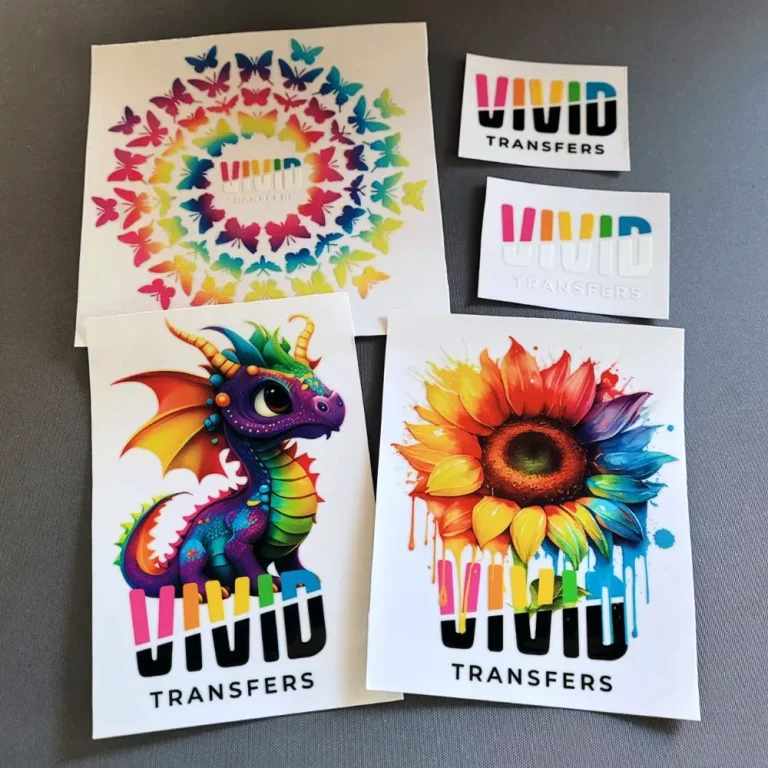

UV DTF Transfers are revolutionizing the printing industry by seamlessly merging efficiency and quality. This innovative technology utilizes UV printing methods to produce vibrant, high-resolution images directly onto various substrates through the DTF printing process. By focusing on superior adhesion and durability, UV DTF transfers allow businesses to meet the growing consumer demand for customizable products that stand out. In this article, we’ll explore essential quality printing tips designed to maximize the effectiveness of UV DTF transfers, ensuring your prints reflect excellence. Whether you are a seasoned professional or a newcomer to the world of printing, understanding heat transfer techniques will empower you to achieve remarkable results.

When discussing advanced printing solutions, terms such as direct-to-film printing transfers often come to mind—yet few techniques offer the versatility of UV DTF transfers. This method, combining UV printing technology with the intricacies of heat application, has quickly become a preferred choice for artists and businesses alike. By harnessing the powers of light-cured inks, you can achieve stunning results on a variety of printing substrates. This article will guide you through optimal processes and preparation techniques to enhance your transfer printing outcomes. As we delve deeper into this topic, we’ll reveal the crucial steps needed to elevate your creativity and output quality in the realm of UV DTF transfers.

The Benefits of UV DTF Transfers for Quality Printing

UV DTF transfers offer a plethora of advantages for businesses seeking high-quality printing solutions. One of the most significant benefits is the ability to print on a wide variety of substrates, including plastics, wood, textiles, and glass. This flexibility allows print shops to diversify their offerings, catering to a broader audience with customized solutions. The UV printing technology employed in DTF transfers ensures that inks cure instantly when exposed to UV light, resulting in vibrant colors and a durable finish that stands up to various environmental conditions.

Moreover, UV DTF transfers eliminate the need for multiple printing steps, streamlining the production process significantly. Since this technique combines both printing and transfer in one seamless operation, it enhances efficiency and reduces the chances of errors that can occur during traditional multi-step processes. As a result, businesses can achieve faster turnaround times, which is crucial in today’s fast-paced market. This combination of quality and efficiency makes UV DTF transfers a preferred choice for professional printing applications.

Best Practices for UV Printing Technology

One of the best practices for utilizing UV printing technology effectively is to ensure compatibility between inks and substrates. High-quality UV inks specifically formulated for DTF transfers are essential for optimal adhesion and color profiles. Investing in quality materials can significantly reduce problems associated with fading and peeling over time. It’s also wise to conduct test prints on the intended substrates to confirm that the ink adheres as expected, providing prints that not only look good but also stand the test of time.

Another essential practice revolves around maintaining a clean printing environment. Dust and contaminants can compromise print quality, so implementing rigorous cleaning protocols before printing sessions is invaluable. Moreover, regular maintenance of printing equipment, including cleaning nozzles and aligning print heads, ensures consistent performance. Adhering to these best practices will help in maximizing the potential of UV printing technology, allowing printers to deliver high-quality, vibrant prints that meet client expectations.

Frequently Asked Questions

What are the benefits of using UV DTF transfers compared to traditional printing methods?

UV DTF transfers combine UV printing technology with heat transfer techniques, offering superior adhesion and vibrant colors on various substrates. Unlike traditional printing methods, UV DTF provides durability and excellent clarity, making it ideal for intricate designs and ensuring high-quality outputs.

How important is substrate preparation in the UV DTF printing process?

Substrate preparation is crucial for UV DTF transfers as it ensures optimal ink adhesion. A clean surface free from dust and contaminants maximizes print quality. Properly preparing the substrate enhances durability, reducing issues like peeling and fading, which are essential for achieving professional results.

What printer settings should I adjust for quality UV DTF transfers?

To achieve high-quality UV DTF transfers, adjusting your printer’s resolution and speed is vital. Higher resolution settings can prevent ink bleeding and maintain sharp details. Slowing down print speed for complex designs can enhance gradients and precision, resulting in more detailed and captivating prints.

What are some common issues in UV DTF transfers, and how can they be solved?

Common issues in UV DTF transfers include smudging, peeling, and poor adhesion. To address these, ensure your printer is properly calibrated and aligned, and use high-quality DTF films. Regular printer maintenance and revisiting setup processes can help troubleshoot and prevent these problems to maintain consistent print quality.

How does the heat pressing technique affect UV DTF transfers?

Heat pressing is critical in the UV DTF process; the temperature and timing influence adhesion and clarity of the final print. Adjusting heat settings to suit specific substrates and experimenting with higher temperatures for shorter durations often lead to superior transfer results, ensuring vibrant and durable outputs.

What post-processing steps should I take after completing UV DTF transfers?

Post-processing steps include allowing adequate curing time for inks to set properly and applying a protective layer or coating. This enhances durability against scratches and environmental damage, ensuring the longevity of your UV DTF prints and maintaining their quality over time.

| Key Aspect | Details |

|---|---|

| Ink and Substrate Compatibility | Choose high-quality UV inks designed for DTF to ensure optimal adhesion and vibrant colors. |

| Optimizing Printer Settings | Adjust resolution and print speed for intricate designs to achieve sharper details and better gradients. |

| Prepping the Substrate | Ensure the substrate is clean and free from contaminants; consider a primer for challenging materials. |

| Heat Pressing Techniques | Experiment with temperature and time settings; use Teflon sheets to prevent sticking. |

| Post-Processing Care | Allow curing time for inks; apply protective coatings to enhance longevity. |

| Troubleshooting Common Issues | Regular maintenance and quality checks can mitigate common problems like smudging or poor adhesion. |

Summary

UV DTF Transfers represent a significant advancement in printing technology, offering exceptional quality prints that cater to a wide range of materials. By understanding the critical factors such as ink and substrate compatibility, printer settings optimization, and thorough post-processing techniques, professionals can greatly enhance the quality of their UV DTF transfers. This process not only ensures vivid colors and durable prints but also positions businesses to meet increasing customer demands for high-quality outputs. Embracing these practices leads to successful outcomes in UV DTF printing, allowing creators and businesses alike to flourish in today’s competitive landscape.