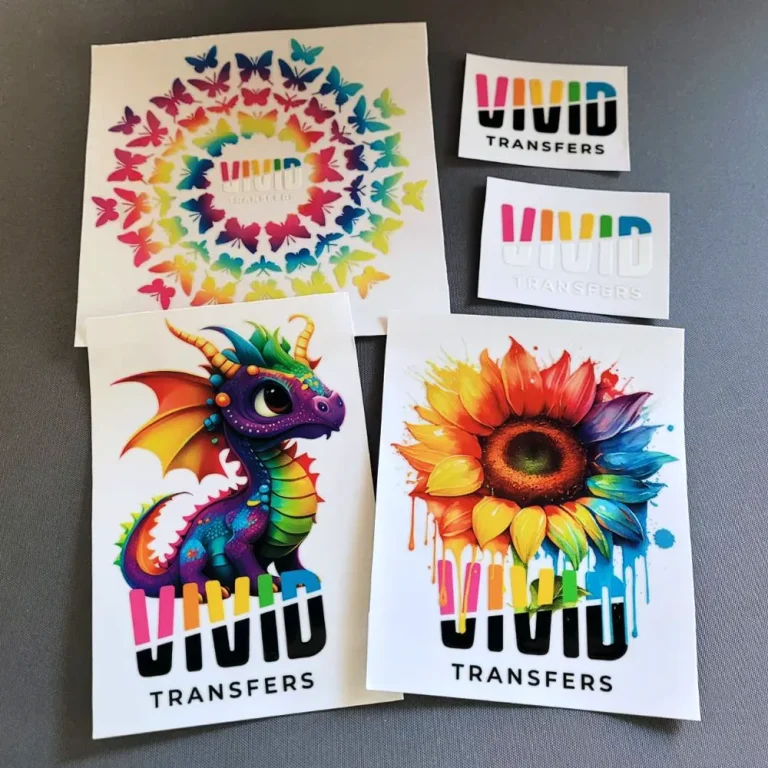

In the realm of modern printing solutions, UV DTF transfers have revolutionized the way we approach design and creativity. Combining the innovative techniques of UV printing and Direct to Film technology, this method offers exceptional versatility and stunning color outputs. Artists and designers alike can leverage UV DTF transfers to create vibrant, durable designs that adhere to a multitude of surfaces. Whether you’re looking to embellish textiles or add flair to rigid materials, understanding the nuances of this printing technique can remarkably enhance your workflow. With the right tools, tips, and creativity, you can unlock endless possibilities in the world of UV DTF transfers.

Also known as UV Direct to Film transfers, this cutting-edge printing approach merges the best aspects of UV technology with Direct to Film practices, creating endless opportunities for artistic expression. This method is ideal for both seasoned professionals and newcomers looking to deepen their knowledge of printing techniques. By integrating UV printing with specialized film, creators can achieve rich, intricate designs that stand the test of time across various mediums. With effective use of design software and essential printing tips, anyone can tap into the unique potential that comes with this advanced technology.

Understanding the Benefits of UV DTF Transfers

UV DTF transfers bring a unique advantage to the world of printing, combining the best features of UV and direct-to-film technologies. The use of UV light not only ensures that the inks cure rapidly, enabling faster production times but also ensures high durability and vibrant colors on a range of surfaces. Whether you want to print on textiles or more rigid materials like metal and glass, UV DTF transfers empower you to explore new creative avenues with speed and precision.

Additionally, these transfers excel in producing intricate designs and vivid imagery with remarkable detail. As this technology continues to improve, it opens up exciting possibilities for designers, allowing them to develop stunning products that stand out in a competitive market. The capability of UV DTF printing to maintain color fidelity and deliver long-lasting prints makes it an ideal choice for businesses looking to make a lasting impression with their branding and merchandise.

Exploring Material Selection for UV DTF Printing

When working with UV DTF transfers, choosing the right substrate can vastly influence the quality and impact of your designs. From clothing to promotional items, every material interacts differently with ink, which is why experimenting with various textures and finishes can yield stunning results. Light and dark textiles provide contrasting canvases that can either absorb or showcase colors vibrantly, making them a thrilling choice for experimenting with creative designs.

Moreover, the versatility of UV DTF technology allows for unique applications on unconventional surfaces, including wood, metal, and plastics. By testing how prints adhere and look on different materials, designers can discover innovative ways to enhance their creative projects. This mixed-media approach not only broadens your design capabilities but also enriches your portfolio, showcasing your ability to adapt and innovate in the printing landscape.

Leveraging Advanced Design Software for Optimal Outcomes

To fully realize the potential of UV DTF transfers, utilizing sophisticated design software is essential. Programs such as Adobe Illustrator and CorelDRAW are crucial tools that designers can use to develop their creative visions into tangible print-ready designs. Advanced color management features offered by these platforms ensure that the output on various substrates remains consistent and accurate, significantly influencing the success of your prints.

Additionally, employing specialized ICC profiles for your particular printer model can enhance color accuracy further. This technical aspect of design software may seem daunting, but mastering it enables designers to manipulate hues effectively and achieve breathtaking results. As a result, spending time to familiarize yourself with powerful design software can dramatically elevate the quality of your UV DTF projects.

Creating Depth and Dimension with Layering Techniques

One of the standout features of UV DTF transfers is the ability to layer inks to create depth and dimension in your prints. By experimenting with layering techniques, such as adding shadows, gradients, or textures, designers can achieve more intricate and captivating artwork that captures the observer’s attention. Incorporating effects like metallic or neon inks can elevate standard designs into striking visuals that resonate with viewers.

Furthermore, the process of layering not only enhances the aesthetic appeal of designs but also allows for customization options that can cater to specific client needs or trends. Using these advanced techniques, you can take standard prints and transform them into collectible pieces or unique products that stand out in today’s saturated market. Embracing this principle of layering can lead you to create a signature style that sets your work apart.

Essential Printer Adjustments for Superior Print Quality

Achieving exceptional print quality with UV DTF transfers hinges on optimizing your printer settings. Factors such as ink density, curing time, and even print speed can significantly affect the final output, which is why fine-tuning these settings according to the substrate is paramount. Regularly testing different configurations allows for identifying the ideal balance, ensuring every print not only meets but exceeds quality expectations.

Maintaining a meticulous record of successful settings benefits your workflow, allowing you to replicate optimal results efficiently. As you gain experience with various materials and designs, the insights gathered through these adjustments will inform your future projects and help streamline your production processes. Ultimately, an astute understanding of printer technology will empower you to deliver the best possible versions of your creative designs.

The Importance of Staying Informed on UV DTF Trends

The printing industry is continuously evolving, and staying up-to-date on the latest trends in UV DTF technology is crucial for any designer looking to expand their creative repertoire. Engaging with industry publications, online forums, and attending trade shows can provide you with essential insights into new materials, techniques, and other innovations that can inspire fresh ideas in your work. Subscribing to platforms that focus on UV printing or creative design can offer a wealth of information to fuel your artistic growth.

Moreover, connecting with a community of professionals who share an interest in UV DTF printing enables collaboration and knowledge-sharing. Participating in discussions can spark inspiration and expose you to different perspectives on design challenges and solutions. In an industry that thrives on creativity, keeping informed about the trends helps you innovate and ensure your work remains relevant and appealing to consumers.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers, or UV Direct to Film transfers, utilize ultraviolet light to cure inks on various substrates like textiles, plastics, and metal. This process involves printing on a specialized film, which is then heat-pressed onto the desired surface, resulting in vibrant and durable designs.

What materials can I use for UV DTF transfers?

UV DTF transfers can be applied to a wide range of materials including light and dark textiles, rigid items, and unconventional surfaces like wood and metal. Experimenting with different textures and finishes can enhance the visual depth of your prints.

Which design software is best for creating UV DTF transfers?

Advanced design software, such as Adobe Illustrator and CorelDRAW, is ideal for creating files optimized for UV DTF transfers. These programs offer powerful color management tools that help achieve accurate color representation and overall print quality.

How can I enhance the depth of designs using UV DTF transfers?

To enhance depth in your UV DTF transfers, experiment with layering techniques and effects. Incorporating textures, gradients, or even using metallic and neon inks can create striking multidimensional artwork within your designs.

What printer settings should I adjust for optimal UV DTF transfer results?

Adjusting printer settings such as ink density and curing time is crucial for achieving high-quality UV DTF transfers. Regular testing and meticulous record-keeping of successful settings will help improve print outcomes over time.

What post-processing techniques can improve UV DTF transfers?

Post-processing techniques such as applying protective coatings or laminates can enhance the appearance and durability of UV DTF transfers. Additionally, adding creative stitching or embellishments can further elevate the final product’s marketability.

| Key Aspects | Description |

|---|---|

| Introduction | UV DTF transfers are innovative printing solutions that combine UV and DTF technologies to create vibrant and durable designs. |

| Overview of UV DTF Transfers | This method uses UV light to cure inks on various surfaces, allowing high color fidelity and quicker production times. |

| Material Selection | Choosing the right substrates, such as textiles, plastics, and metals, is crucial for unique creative results. |

| Advanced Design Software | Utilizing software like Adobe Illustrator enhances color accuracy and file optimization. |

| Layering and Effects | Creating depth through layering and using different inks can produce multidimensional artwork. |

| Printer Settings | Adjusting ink density and curing time is key for achieving optimal print quality. |

| Post-Processing Techniques | Applying protective coatings and creative embellishments can enhance design durability and appeal. |

| Staying Updated | Engaging with industry trends helps inspire creativity and innovation in designs. |

Summary

UV DTF transfers present an exciting opportunity for creative expression in the world of printing. By following expert tips such as selecting the right materials, utilizing advanced design software, experimenting with printer settings, and enhancing designs through post-processing, designers can unlock the full potential of this innovative technology. The ability to create vibrant, durable prints enhances not just the creative process but also the final product’s marketability. Embrace the power of UV DTF transfers to elevate your artistic ventures.