In the rapidly evolving world of printing, **UV DTF transfers** have emerged as a game-changing method that combines the advancements of Direct to Film (DTF) technology with the cutting-edge capabilities of UV printing technology. This innovative approach not only enhances the vibrancy and durability of printed designs but also expands the creative possibilities for businesses. As the demand for custom printing techniques grows, integrating UV DTF transfers can significantly bolster printing business growth and profitability. This article delves into the transformative benefits of UV DTF printing, helping businesses leverage these techniques effectively. Discover how embracing UV DTF can set your printing services apart in an increasingly competitive market.

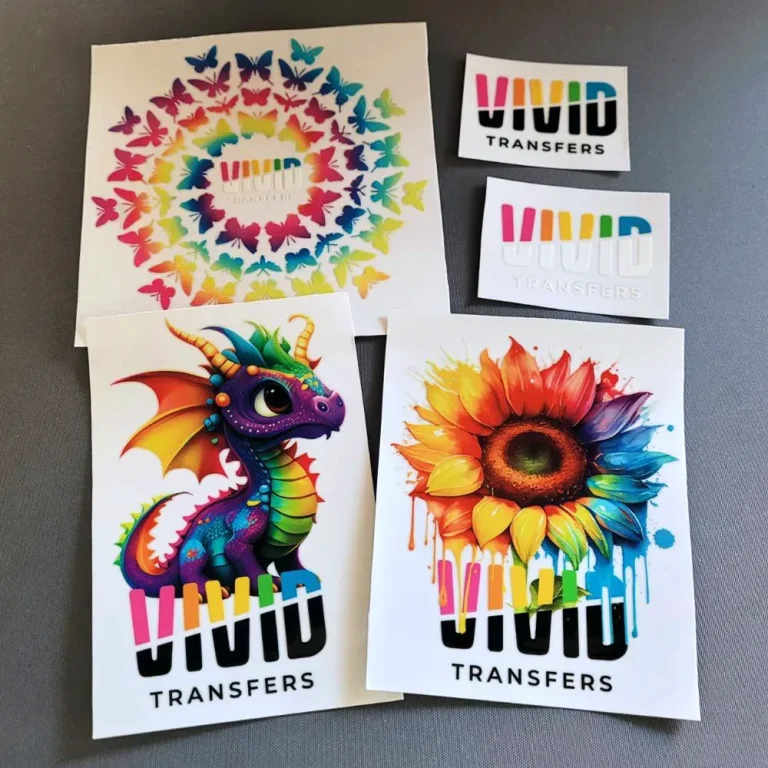

UV Direct to Film transfers represent a revolutionary approach in the printing industry, enabling businesses to produce eye-catching designs with unmatched quality. Often referred to simply as DTF printing, this method utilizes ultraviolet light to cure inks on a specialized film before transferring them to various substrates. The versatility of this technique allows printers to cater to diverse markets, from fashion to promotional items. With the rising popularity of custom print solutions, exploring these advanced printing techniques can unlock new opportunities for growth and customer outreach. By adopting UV DTF methods, companies can not only enhance their product offerings but also streamline their operational processes.

Understanding UV DTF Transfers and Their Mechanism

UV DTF (Direct to Film) Transfers represents a significant shift in printing technologies. This method utilizes ultraviolet light to cure ink directly onto a transfer film. The process involves first printing the design onto the film, followed by exposure to UV light which instantly solidifies the ink. This innovation allows businesses to produce vibrant and intricate designs with remarkable ease and flexibility. Moreover, the UV curing process reduces the risk of smudging and enhances the durability of the print, making it ideal for a variety of materials.

By harnessing the capabilities of UV DTF technology, printing companies can cater to an expansive market, including apparel, signage, and promotional products. This versatility extends to printing on diverse substrates like textiles, metals, and even plastic surfaces. The ability to quickly shift between various applications increases the operational efficiency of printing businesses and significantly broadens their service offerings, thus tapping into new revenue streams.

The Benefits of Integrating UV DTF Printing

One of the most compelling advantages of integrating UV DTF printing into your business model is the sheer vibrancy of colors. Unlike traditional printing methods that may require multiple layers to achieve depth, UV DTF processes yield rich colors in a single pass. This allows for high-quality finishes that catch the eye and meet customer expectations for aesthetic appeal. The bold colors combined with sharp details can enhance the overall product offering and promote brand recognition.

Moreover, UV DTF prints showcase an impressive level of durability. Unlike conventional transfers that may fade or peel over time, UV-cured prints withstand exposure to various environmental factors, including moisture and sunlight. This longevity not only bolsters customer satisfaction through quality assurance but is also an attractive selling point for businesses that prioritize sustainability and long-lasting products. Companies can assure clients that their custom prints will maintain integrity and appearance under diverse conditions.

Market Trends and the Rise of UV DTF Printing

The printing industry is witnessing a seismic shift as trends increasingly favor customization and high-quality outputs. The rise of UV DTF printing aligns perfectly with consumer demands for unique, personalized products. As shopping behaviors evolve, customers are prioritizing brands that offer tailored solutions, making it imperative for printing businesses to adopt innovative methods like UV DTF. This adaptation is not just a trend but a requirement for survival and growth in the modern market.

Reports indicate that sectors such as fashion, merchandise, and promotional products are driving the demand for DTF solutions. As a result, businesses integrating UV DTF technology not only meet immediate customer needs but position themselves for future growth. The ongoing evolution of these technologies suggests that using UV DTF techniques will be a key factor in corresponding with market dynamics and thriving amid competitive pressures.

Quality Control Strategies in UV DTF Printing

Quality control is fundamental to the success of any printing operation, especially when implementing a sophisticated technology like UV DTF printing. It’s crucial for businesses to establish rigorous quality assurance protocols at each stage of production. Regular quality checks help ensure that colors are accurately represented, and the details within prints are sharp. Investing in high-quality inks and maintaining equipment can significantly elevate the final output, ultimately leading to enhanced customer satisfaction.

Moreover, businesses should consider the consistency of their prints. Even the smallest variations can lead to dissatisfaction, particularly in custom printing scenarios where clients expect uniform quality in bulk orders. Utilizing digital quality control tools and metrics can assist operators in identifying issues before they escalate, creating a culture of excellence that bolsters the brand’s reputation within the printing industry.

Advanced Software Solutions for Printing Optimization

Incorporating advanced design software into UV DTF printing operations can dramatically enhance productivity and output quality. These tools enable businesses to manage color settings effortlessly, ensuring that the vibrancy and fidelity of prints correspond closely with customer expectations. Software solutions that specialize in graphic design can streamline workflows and allow teams to make real-time adjustments, reducing production time and errors.

Additionally, adopting software that integrates directly with UV printing equipment allows for better handling of complex projects. As printing technologies evolve, the ability to utilize sophisticated design programs that accommodate various substrates and designs becomes crucial. This emphasis on using technology not only maximizes output quality but also enhances the creativity involved in custom printing, ultimately leading to increased sales opportunities.

Emerging Opportunities in Diverse Applications Beyond Textiles

While textiles remain a significant focus for UV DTF transfers, the potential applications are much broader. Expanding into signage presents lucrative opportunities for printing businesses, allowing them to create eye-catching displays that feature logos, graphics, and important information for various enterprises. The resilience of UV prints makes them ideal for outdoor use, enhancing their appeal as businesses seek durable yet attractive solutions.

Promotional items also serve as a viable avenue for growth. Printing on products such as mugs, phone cases, and keychains with UV DTF technology enables companies to offer unique branding options that resonate with clients. As promotional campaigns increasingly lean towards personalization, incorporating customized UV DTF prints can make products stand out, thereby capturing attention in competitive markets. This diversity not only enhances a company’s service portfolio but also attracts a wider range of clients.

Frequently Asked Questions

What is UV DTF Transfers and how does it work?

UV DTF (Direct to Film) Transfers use ultraviolet curing technology to allow vibrant prints to be seamlessly transferred onto various surfaces. This technique applies UV inks to a special film, which is then heat pressed onto substrates like textiles, plastics, and metals, achieving high-quality, durable prints.

What are the main benefits of using UV DTF Transfers in my printing business?

Utilizing UV DTF Transfers provides several benefits including vibrant color output, enhanced durability, and versatility across multiple substrates. This method is also cost-effective compared to traditional printing techniques, which can positively impact your printing business growth and profit margins.

Can UV DTF Transfers be used on different materials?

Yes, UV DTF Transfers are highly versatile and can be applied to various materials including textiles, plastics, and metals. This adaptability allows printing businesses to expand their service offerings and cater to a broader clientele by exploring different applications.

How does UV DTF Transfers compare to traditional DTF printing?

While both UV DTF Transfers and traditional DTF printing share similar foundations, UV DTF employs ultraviolet curing, resulting in brighter colors and greater durability. This technological advancement helps businesses achieve superior print quality, making it an attractive choice for custom printing techniques.

What equipment is needed for UV DTF printing?

Investing in advanced UV printers specifically designed for DTF printing is essential. These printers have become more affordable, and their capabilities enable printing businesses to compete effectively in the market, providing high-quality output while maintaining efficiency.

What strategies can I use to maximize my printing operations with UV DTF Transfers?

To maximize your printing operations with UV DTF Transfers, focus on quality control, utilize advanced design software for color management, and explore diverse applications for your prints. Additionally, investing in staff training and staying abreast of market trends will enhance productivity and customer satisfaction.

| Key Points | Details | |

|---|---|---|

| Definition | UV DTF transfers utilize UV light to cure inks onto a special film, allowing high-quality prints on various surfaces. | |

| Advantages | Vibrant colors, durability, versatility, and low production costs make UV DTF transfers appealing for businesses. | |

| Popularity Growth | The DTF market is rapidly expanding, driven by demand from sectors like fashion and custom merchandising. | |

| Maximization Techniques | Implement quality control, use advanced design software, and explore diverse applications to maximize business potential. | |

| Equipment Investment | Invest in advanced UV DTF printers and ensure staff are trained on color management and substrate compatibility. | |

| Success Stories | Businesses have reported increased sales and customer satisfaction after adopting UV DTF technologies. | |

Summary

UV DTF Transfers represent a significant advancement in the printing industry, offering businesses a practical solution to meet the rising demand for high-quality custom prints. By leveraging the unique capabilities of UV DTF technology, companies can achieve vibrant colors, durability, and versatility in their offerings. As the market continues to evolve, embracing UV DTF Transfers not only enhances printing efficiency but also allows businesses to cater to a diverse clientele eager for customized products. Staying informed and adaptive to these innovations will position printing businesses for sustained growth and success.