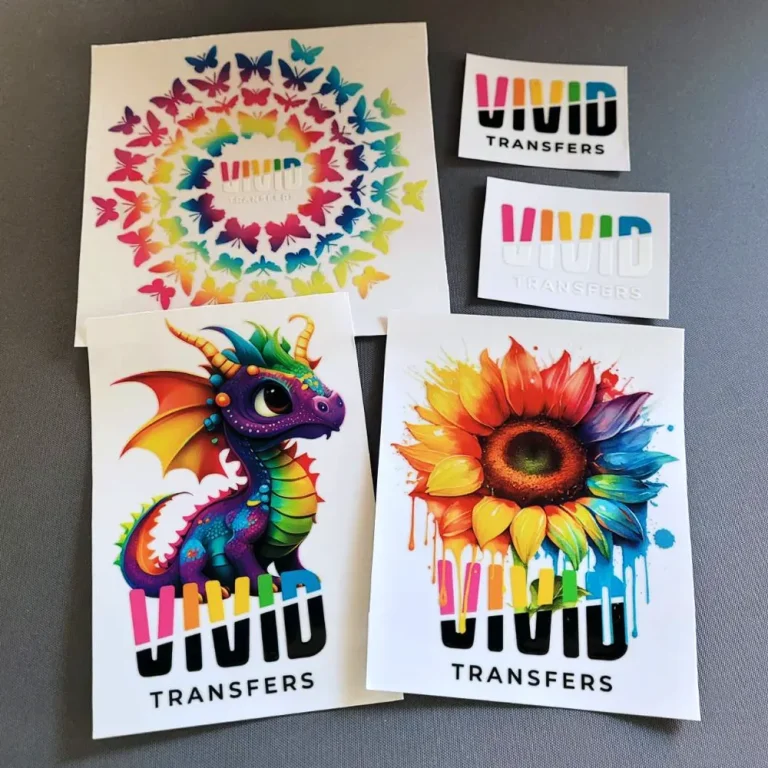

As the world of print design evolves, UV DTF transfers have emerged as a revolutionary technique that allows designers to push the boundaries of creativity. Utilizing ultraviolet light to cure inks on specially designed films, this method produces eye-catching, vibrant designs on a variety of substrates including fabrics, plastics, and metals. Artists and designers who master UV DTF printing techniques find themselves with endless possibilities to create unique and high-quality DTF transfers that not only stand out but also endure the test of time. In this guide, we’ll delve into creative UV DTF design tips that will help you transform your artistic visions into reality. Embrace the potential of UV DTF as we explore ways to enhance your design workflow and maximize your creative output.

The concept of UV DTF, or Direct-to-Film, printing has gained significant traction among contemporary designers looking for innovative solutions to their printing challenges. This advanced printing technology harnesses the power of ultraviolet curing to deliver stunningly vivid prints that adhere flawlessly to a wide range of materials. By exploring various UV DTF printing methods, designers can achieve exceptional durability and detail in their artwork. This exploration includes practical tips for successful DTF projects, ensuring that every print accurately reflects the artist’s vision. Ultimately, embracing this technique can unlock new creative avenues, making it a game changer in the world of design.

Why UV DTF Transfers are Revolutionizing Print Design

UV DTF transfers have quickly become a game-changer in the realm of print design. This innovative technique utilizes ultraviolet light to cure vibrant inks onto specialized films, which can then be applied to a variety of substrates such as textiles, plastics, and metals. Designers are particularly drawn to UV DTF transfers due to their ability to deliver high-quality, long-lasting prints that maintain color vibrancy over time. With the growing demand for unique and customized products, UV DTF’s versatility offers significant opportunities to cater to diverse market needs.

Moreover, UV DTF transfers facilitate intricate designs that traditional printing methods may not easily achieve. For instance, the ability to print white or metallic inks allows designers to create stunning visuals that stand out on dark or colored materials. As more designers embrace this technology, understanding how to leverage the advantages of UV DTF will be pivotal for creating unique products that captivate customers.

Essential Practices for Enhancing Creative UV DTF Designs

When designing with UV DTF transfers, creativity can flourish when certain practices are meticulously followed. One of the most significant tips is to start with high-resolution artwork. Designs should be created at resolutions of at least 300 DPI to ensure that every detail is beautifully rendered in the finished print. This not only guarantees sharp visuals but also plays a vital role in maintaining the integrity of the design during the transfer process.

Additionally, adopting an RGB color profile during the design phase is essential. Since UV printers operate primarily in RGB, this approach minimizes color shifts often encountered during conversions to CMYK, helping to deliver true-to-life colors in the final product. Implementing these practices can dramatically enhance the overall quality and appeal of creative UV DTF designs.

Material Matters: Selecting the Best Substrates for UV DTF Transfers

Choosing the right substrate for UV DTF transfers is crucial for achieving optimal print quality. Not all materials yield the same results with UV inks; thus, compatibility is key. Substrates such as smooth plastics and certain coated fabrics are known for their excellent adhesion properties, ensuring that designs remain vibrant and intact for longer periods. Conversely, rough or untreated surfaces can lead to challenges in bonding, reducing the lifespan of prints.

By experimenting with various substrates, designers can discover which materials enhance their specific designs. Utilizing surfaces that come with a smooth finish will often result in cleaner, sharper prints. This exploration of compatible materials not only elevates the print quality but also pushes creative boundaries, allowing for unique applications in the print design industry.

Leveraging Design Software for UV DTF Transfers

The proper use of design software can significantly enhance the process of creating designs intended for UV DTF transfers. Programs like Adobe Illustrator and CorelDRAW offer powerful tools for developing intricate designs while maintaining high quality. Working with vector graphics is particularly beneficial as it allows for resizing without losing clarity, accommodating various product dimensions and ensuring designs remain sharp and professional.

Incorporating layer management techniques within these applications also aids in achieving a polished final product. By strategically organizing colors and effects, designers can tweak and perfect their creations more efficiently. Such proficiency in design software not only aligns with high-quality DTF transfer production but also fosters greater creative freedom throughout the design process.

Mastering the Curing Process for Optimal UV DTF Quality

Understanding the UV curing process is paramount when it comes to the quality of UV DTF transfers. Proper exposure to ultraviolet light during curing is essential; inadequate or excessive exposure can compromise the durability and appearance of the prints. Striking the right balance fosters both vibrant colors and a robust finish, allowing designs to withstand various environmental factors.

Temperature control also plays a crucial role in this process. Keeping a consistent ambient temperature promotes uniform curing across all prints, which is particularly important in larger production runs. Mastering these elements of the curing process can greatly influence the longevity and overall success of UV DTF transfers, enabling designers to deliver high-quality products consistently and effectively.

Innovative Techniques to Elevate Your UV DTF Designs

Creativity knows no bounds when it comes to UV DTF design, especially when integrating innovative techniques. For instance, experimenting with layering different colors and finishes can enrich the visual appeal of your prints. Combining matte and glossy elements creates a stunning contrast that draws the eye while adding depth to the overall design.

Incorporating mixed media into UV DTF designs is another fantastic way to break away from the ordinary. By blending materials like vinyl or foils with traditional UV DTF transfers, designers can produce eye-catching textures that enhance the tactile quality of their creations. This approach opens up a world of possibilities, allowing designers to craft standout pieces that push the limits of conventional print aesthetics.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers are a printing technique that utilizes ultraviolet light to cure inks applied to films, allowing designers to produce vibrant, high-quality prints. This method is versatile and compatible with various substrates, enhancing the creativity of print designs.

What are the best materials to use with UV DTF transfers?

For optimal results with UV DTF transfers, consider using compatible substrates such as smooth plastics, metals, and specific types of fabrics. These materials improve adhesion and durability, ensuring that your high-quality DTF transfers remain vibrant and intact.

How can I prepare my artwork for UV DTF printing?

To prepare artwork for UV DTF printing, ensure high resolution (300 DPI or more) and use an RGB color profile to minimize discrepancies. Incorporating vector graphics also allows your design to be resized without loss of quality, essential for achieving the best results.

What are some creative design tips when using UV DTF printing techniques?

When designing with UV DTF printing techniques, experiment with layering colors and finishes, and consider integrating mixed media elements. Using a combination of matte and gloss layers can add depth, making your designs visually captivating.

How can I ensure the quality and durability of my UV DTF transfers?

Conducting test prints will help evaluate color accuracy and adhesion on selected substrates. Additionally, performing stretch and wash tests on samples ensures that your high-quality DTF transfers can withstand daily use and remain durable.

What recent advancements are influencing UV DTF technology?

Recent advancements in UV DTF technology include new eco-friendly ink formulations that enhance the durability and flexibility of transfers while minimizing environmental impact. Keeping up with these developments can further improve creative design capabilities in UV DTF printing.

| Key Aspect | Details |

|---|---|

| Artwork Preparation | Focus on high-resolution images (300 DPI) and use RGB color profiles for best color results. |

| Material Selection | Choose compatible substrates like plastics and metals for optimal results, and prefer smooth surfaces for better print quality. |

| Design Software Proficiency | Utilize vector graphics and manage layers effectively for better design control and quality. |

| Curing Process | Make sure to maintain proper exposure and temperature control during the curing process to enhance print durability. |

| Experimentation and Creativity | Incorporate layering techniques and mixed media for unique and visually appealing designs. |

| Quality Checks | Perform test prints and durability tests to ensure high-quality outcomes. |

| Recent Developments | Continued advancements in UV DTF technology focus on eco-friendly inks and enhanced durability. |

Summary

UV DTF Transfers have revolutionized the print design industry by marrying technology and creativity. This groundbreaking method allows for vibrant and long-lasting designs on a variety of materials, making it a favorite among designers. To fully harness this technique, it is essential to focus on several key aspects such as artwork preparation, material selection, and effective use of design software. Moreover, proper curing processes and regular quality checks ensure that the final product meets high standards. Encouraging experimentation with different techniques can significantly enhance the creativity displayed in designs. Keeping up with recent advancements in the field will also offer designers new opportunities to innovate and push the boundaries of their artwork.