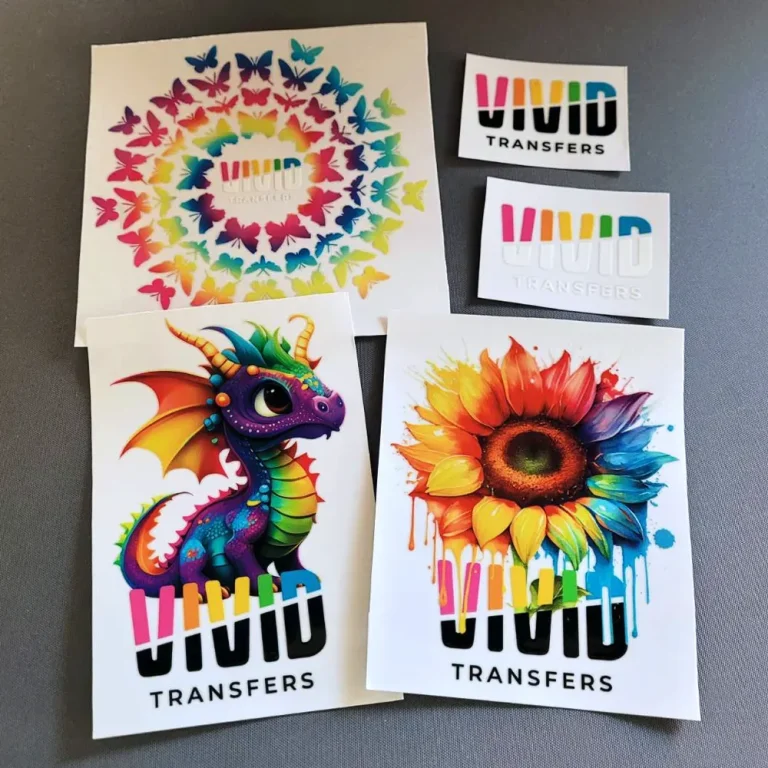

In today’s rapidly evolving printing landscape, UV DTF transfers are revolutionizing the way we think about high-quality prints and their applications. By leveraging cutting-edge Direct-to-Film printing technology, this method is pushing the boundaries of traditional screen printing, providing vibrant and durable images that are unmatched. Unlike older methods, UV DTF transfers not only offer stunning results but also prioritize environmentally friendly printing practices, making them a smart choice for sustainable production. As industries increasingly seek efficient and versatile printing solutions, the advantages of UV DTF transfers become increasingly clear. In this blog, we will explore how this innovative printing advancement can maximize your prints and elevate your business offerings.

UV Direct-to-Film printing, often simply referred to as DTF transfers, represents a significant technological leap in the realm of professional printing. This contemporary method is setting new standards, especially when compared to traditional techniques like screen printing. With a focus on delivering not just exceptional quality, but also environmentally conscious alternatives, UV DTF printing is reshaping industry approaches to print production. The technology facilitates the creation of stunning, durable images suitable for a wide range of materials, paving the way for both creativity and sustainability in printing practices. As we delve deeper, the myriad benefits of adopting UV DTF technologies will reveal why it is quickly becoming a preferred solution for modern print needs.

The Evolution of Direct-to-Film Printing

Direct-to-Film (DTF) printing has transformed the landscape of printing technology over recent years. This method allows for printing designs directly onto a special film, which can then be transferred onto various materials. With continued advancements, DTF printing has found new competitors such as UV DTF transfers. Unlike traditional methods, UV DTF employs ultraviolet light to cure the inks rapidly, ensuring vibrant and lasting prints. This evolution highlights a notable shift in how prints are produced and consumed in today’s market.

The surge in popularity of DTF printing can be attributed to its versatility and quality. However, as UV DTF transfers emerge, they represent a significant evolution in the technology, providing advantages such as lower energy consumption and reduced environmental impact. Given the rapid advancements in this field, businesses are encouraged to stay informed about these innovations to maximize their production capabilities while maintaining high standards.

Advantages of UV DTF Transfers in Comparison to Traditional Methods

When comparing UV DTF transfers to traditional screen printing methods, the benefits are clear. One of the main advantages of UV DTF is the superior print quality it offers. The ability to produce intricate designs with vivid colors and fine details sets it apart from older printing techniques. UV DTF transfers excel in delivering products that stand up to high wear and tear, ensuring that prints remain intact and vibrant over time.

Additionally, traditional screen printing methods are often associated with longer processing times and require significant setup changes for different designs. In contrast, the UV DTF process facilitates a streamlined production workflow, allowing for quick adjustments and faster turnaround times without sacrificing quality. This efficiency not only improves operational productivity but also helps meet the growing demands of today’s customers.

Environmental Benefits of UV DTF Printing Technology

Sustainability is increasingly important in the realm of printing, and UV DTF transfers offer significant environmental advantages. One notable aspect is the reduction of volatile organic compounds (VOCs) emitted during the printing process. The UV inks used in this technology generally feature lower VOC levels, creating a safer atmosphere for employees and minimizing the ecological footprint associated with printing.

Moreover, the energy efficiency associated with UV DTF printing is noteworthy. Unlike conventional methods, UV DTF transfers require less energy for the curing process. This not only translates to cost savings for businesses but also contributes positively to their sustainability goals. As companies seek to adopt greener practices, UV DTF represents an innovative approach to environmentally conscious printing solutions.

Enhancing Productivity with UV DTF Transfers

In a competitive landscape where time is of the essence, UV DTF transfers enhance productivity through their rapid production capabilities. Traditional printing methods often rely on lengthy curing times, which can bottleneck production schedules. However, UV DTF technology cures nearly instantly, drastically reducing turnaround times and allowing businesses to fulfill large orders more efficiently.

This heightened efficiency is instrumental for companies that need to meet tight deadlines and cater to fluctuating market demands. By integrating UV DTF transfers into their operations, businesses can significantly streamline their workflows, ensuring they remain agile and responsive to customer needs while still delivering high-quality prints.

Cost-Effectiveness of Investing in UV DTF Technology

While the initial investment in UV DTF printing technology may be substantial, the long-term financial benefits often justify the expense. The precision that comes with UV DTF printing means fewer mistakes and, consequently, less wasted material. This operational cost reduction, combined with the durability of the products, ensures that businesses can mitigate costs over time, making it a financially sound choice.

Additionally, the longevity of prints produced via UV DTF transfers translates into fewer reprints required. This not only maximizes profitability for businesses but also encourages a more sustainable approach to production. As noted by industry experts, integrating UV DTF technology can enhance both the bottom line and the environmental commitment of printing companies.

Versatile Applications of UV DTF Transfers

The versatility of UV DTF transfers allows them to be utilized across various industries and applications. Unlike traditional screen printing, which is often limited to specific substrates, UV DTF technology can effectively print on diverse materials such as plastics, glass, and metals. This capability broadens the scope of what businesses can offer to their customers, catering to a wider range of needs and preferences.

Furthermore, the creative possibilities are nearly limitless with UV DTF transfers. This technology empowers businesses to explore new aesthetic avenues, ensuring that they stay in tune with current trends and consumer demands. By enhancing their product lines through innovative printing methods, companies can capture a larger market share and build stronger customer loyalty.

Frequently Asked Questions

What are UV DTF transfers in comparison to traditional screen printing?

UV DTF transfers use ultraviolet light to quickly cure ink on film, providing sharp, durable prints that stand out against traditional screen printing, which may result in longer production times and less detail.

How do UV DTF transfers contribute to environmentally friendly printing practices?

UV DTF transfers utilize inks with lower volatile organic compounds (VOCs) and consume less energy during curing, making them a more sustainable option compared to other printing technologies.

Why choose UV DTF transfers for producing high-quality prints?

The technology behind UV DTF transfers enables vivid colors and intricate designs, ensuring that high-quality prints maintain their clarity and durability over time, outperforming many other printing methods.

What cost benefits can businesses expect from UV DTF transfer printing?

While the initial equipment cost for UV DTF transfers might be higher, businesses can save on material waste and maintenance in the long run, making it a cost-effective solution for high-volume printing.

In what applications are UV DTF transfers most beneficial?

UV DTF transfers are versatile and can be applied to a range of substrates including plastics, metals, and glass, allowing for a wider array of creative possibilities compared to traditional methods.

How does the efficiency of UV DTF transfers compare with other printing technologies?

UV DTF transfers offer rapid production speeds due to instant curing, which leads to quicker turnaround times and increased productivity compared to traditional DTF and screen printing methods.

| Key Point | Description |

|---|---|

| Quality and Durability | Type of printing that achieves vivid and detailed prints, ensuring long-lasting effects against wear and tear. |

| Environmental Impact | Features low VOC emissions and energy-efficient processes that contribute to sustainability in printing. |

| Efficiency and Speed | Offers rapid production capabilities with quick curing times, leading to increased productivity and lower operational costs. |

| Cost-Effectiveness | Initial costs may be high, but reduced material waste and longevity make it a financially smart choice for businesses. |

| Application Range | Versatile printing capabilities on multiple substrates, broadening creative possibilities and catering to various industries. |

Summary

UV DTF Transfers represent a revolutionary advancement in the printing industry, offering unparalleled advantages that set them apart from traditional methods. One of the primary benefits is their exceptional print quality, providing vibrant images and intricate details that are crucial for modern promotional materials. Additionally, the environmental benefits associated with low VOC emissions underscore the sustainability aspect of UV DTF Transfers, attracting eco-conscious businesses. Furthermore, the rapid production speed inherent to this technology significantly boosts efficiency, allowing companies to meet tight deadlines without sacrificing quality. Long-term, UV DTF Transfers promise cost-effectiveness through reduced waste and durable print output, making them an ideal choice for high-volume print operations. The versatility of UV DTF Transfers across various substrates opens up exciting avenues for innovation, keeping businesses aligned with evolving market trends. Ultimately, investing in UV DTF Transfers equips companies to thrive in a competitive landscape, making it a compelling option for forward-thinking print professionals.