UV DTF transfers have emerged as a game-changer in the realm of custom printing, offering unparalleled customization options for businesses eager to stand out. This innovative technology harnesses the power of UV printing, seamlessly blending it with DTF methods to produce stunning, high-quality designs on a vast array of materials. With the growing demand for personalized products, UV DTF transfers deliver vibrant prints that not only catch the eye but also endure the test of time. As we dive into this exciting topic, we’ll uncover the numerous benefits and applications of UV DTF technology, solidifying its position as a leader in the transfer printing market. Join us on this journey to explore how UV DTF transfers can elevate your brand and meet the rising expectations of consumers seeking unique creations.

In the ever-evolving landscape of printing technology, Direct to Film (DTF) transfers utilizing ultraviolet (UV) ink represent the forefront of customization capabilities. This technological advancement merges traditional transfer printing methods with cutting-edge UV printing technology, enabling businesses to create personalized products that resonate with consumers. By employing special films and curing inks with UV light, this process ensures robust and vibrant results suitable for a variety of substrates. As we further investigate this revolutionary approach, we will highlight the distinctive advantages and potential of these innovative printing techniques, thriving in a market that increasingly demands customization.

Understanding UV DTF Transfers: A Breakdown

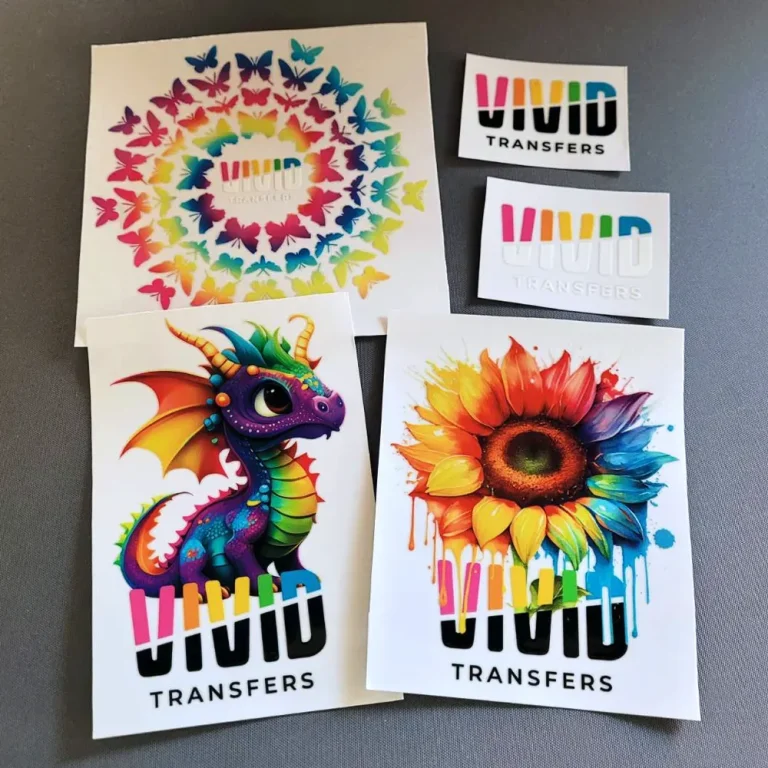

UV DTF transfers are an innovative printing technology that merges the strengths of UV printing with the versatility of Direct to Film (DTF) methods. This process involves using UV-curable inks to print designs onto a special film, which is then transferred onto various substrates. The prints created through this method are not only vivid and colorful, but they also have remarkable durability, making them suitable for both indoor and outdoor use. The ability to print on diverse materials such as textiles, wood, and glass offers businesses a unique opportunity to expand their product offerings.

Furthermore, the efficiency of UV DTF transfers cannot be overlooked. The use of UV inks allows for quick drying times due to the immediate curing process that involves ultraviolet light. This allows for faster production turnaround, catering to the increasing demand for personalized products in today’s market. As customization becomes a driving force in consumer purchasing decisions, understanding the nuances of UV DTF technology is crucial for businesses looking to streamline their operations and meet consumer expectations.

The Advantages of UV DTF Transfers in Custom Printing

One of the most significant advantages of UV DTF transfers is their versatility. Unlike traditional printing methods that are often limited to specific substrates, UV DTF technology allows for customization on a wide range of materials. This is particularly advantageous for businesses that aim to offer personalized products, as customers can select their preferred materials without compromising on quality. Whether it’s fashion apparel, promotional items, or unique home décor, UV DTF transfers provide the flexibility needed to satisfy diverse consumer needs.

Moreover, the durability of UV cured inks is well-documented. These inks resist fading, scratching, and other wear, ensuring that personalized products maintain their appearance over time. This durability is notably important in industries where items are regularly exposed to the elements or where high usage is typical. Investing in UV DTF technology not only enhances product offerings but positions companies to better serve their clientele, leading to heightened customer satisfaction and loyalty.

The Customization Trend: Capitalizing on UV DTF Technology

As businesses look to capitalize on the growing demand for customized products, UV DTF technology emerges as a powerful ally. With consumers increasingly desiring bespoke items, companies that invest in UV DTF printing are able to respond effectively to market trends. This technology supports a range of applications, ensuring that businesses can meet varied consumer preferences—from customized apparel to personalized promotional materials.

The shift towards personalization also means that companies can differentiate themselves in a competitive marketplace. By utilizing UV DTF technology, brands can offer innovative solutions that not only fulfill customer expectations but also exceed them. By creating unique and memorable products using custom printing, businesses are likely to see increased brand loyalty and a stronger connection with their customer base.

Integration of UV DTF Technology with Modern Printing Solutions

The integration of UV DTF technology into contemporary digital printing workflows is a growing trend within the industry. This hybrid approach enhances operational efficiency and allows printing service providers to reduce turnaround times significantly. By embracing UV DTF transfers, companies can streamline their processes, ensuring they remain competitive while accommodating the rising demand for swift and efficient service.

In addition to improving efficiency, the implementation of UV DTF technology often reduces waste associated with traditional printing methods. This shift toward sustainable practice is becoming increasingly important as consumers lean towards brands that prioritize environmental responsibility. By adopting UV DTF techniques, businesses position themselves as leaders in both quality and sustainability, appealing to a modern, eco-conscious market.

Future Innovations in UV DTF Technology

Looking forward, the future of UV DTF technology seems promising, particularly with ongoing advancements aimed at improving efficiency and adaptability in the printing process. Innovations may encompass real-time color management systems that enhance accuracy and consistency, or automated printing solutions that increase production capabilities. As the demands of consumers continue to evolve, staying at the forefront of technological advancements will be critical for businesses seeking to optimize their printing solutions.

Additionally, as UV DTF transfers gain traction, companies operating within this space will likely see an increase in the complexity of customization options available to consumers. Enhanced features could allow for more intricate designs and a broader array of color choices, further broadening the appeal of personalized products. For businesses, harnessing these innovations means not only meeting current demands but understanding and anticipating future trends in custom printing, thereby maintaining a competitive edge.

Conclusion: Embracing the Future of Printing with UV DTF Transfers

In conclusion, UV DTF transfers are transforming the landscape of printing and customization. The advantages offered by this innovative technology—such as versatility, durability, and vibrancy—enable businesses to produce high-quality personalized products that stand out. For companies that embrace UV DTF technology, the potential for growth and differentiation in a crowded market is immense.

As consumer expectations continue to rise, the strategic incorporation of UV DTF transfers can provide businesses with the tools needed to thrive. By investing in advanced printing technologies, companies not only enhance their production capabilities but also position themselves as leaders in an increasingly customized world.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers utilize ultraviolet ink printed on a special film, which is then applied to different substrates such as textiles and metal using heat and pressure. This technology allows for vibrant, high-quality prints that are durable and resistant to wear.

What materials can UV DTF transfers be applied to?

UV DTF transfers can be applied to a wide variety of materials, including textiles, wood, glass, and metal. This versatility makes them ideal for custom printing on personalized products across different industries.

What are the durability benefits of using UV DTF transfers?

UV DTF transfers offer high durability due to the use of UV inks, which are resistant to fading, scratching, and washing. This ensures that the printed designs maintain their vibrancy and quality over time, even with frequent use.

How do UV DTF transfers compare to traditional printing methods?

UV DTF transfers stand out from traditional printing methods by providing better vibrancy, durability, and versatility. The quick-drying UV inks allow for intricate designs and faster turnaround times, making them a preferred choice for many businesses.

Why is the demand for UV DTF transfers growing in the customization market?

The demand for UV DTF transfers is increasing as consumers seek personalized products. Businesses that adopt this technology can meet the rising consumer expectations for unique and high-quality merchandise, driving their success in the competitive market.

What future advancements can we expect in UV DTF printing technology?

The future of UV DTF printing technology may include developments such as real-time color management, automated systems, and enhanced customization features. These advancements are expected to improve efficiency and further elevate the quality of custom printing options.

| Key Points | Description |

|---|---|

| Introduction | Overview of UV DTF transfers and their impact on customization in printing. |

| What Are UV DTF Transfers? | Printing UV ink on film, which is then applied to substrates with heat and pressure for high-quality, durable prints. |

| Advantages | Includes versatility across materials, high durability of prints, and vibrant detail in designs. |

| Growth in Customization Market | Increasing consumer demand for personalized products is boosting UV DTF adoption. |

| Integration with Modern Technology | Enhances efficiency and sustainability in printing processes, appealing to environmentally-conscious consumers. |

| Future Perspectives | Potential advancements in printing efficiency, automated systems, and enhanced customization options. |

| Conclusion | Emphasizes the need for companies to adopt UV DTF technology for competitive advantage in a customizable market. |

Summary

UV DTF transfers are revolutionizing the world of customization in printing, offering businesses a powerful method to create vibrant, high-quality products that meet the evolving demands of today’s consumers. This technology harnesses the benefits of UV printing combined with the flexibility of DTF processes, making it an ideal solution for a diverse range of applications—from textiles to promotional items. The ability to print intricate designs rapidly and with great durability enables companies to stand out in a crowded marketplace. As businesses increasingly lean into customization, those that embrace UV DTF transfers will find themselves well-positioned to capture consumer interest and remain competitive in a dynamic landscape.