In the rapidly evolving landscape of customized merchandise, UV DTF transfers have emerged as a groundbreaking innovation. This advanced printing technology utilizes UV light to create vibrant and durable prints directly from film to surface, revolutionizing the way businesses produce personalized products. By streamlining the production process and offering cost-effective solutions, UV DTF transfers enable companies to cater to diverse consumer demands without compromising on quality. Additionally, these sustainable printing solutions align with the increasing consumer preference for eco-friendly options, making them a responsible choice for environmentally conscious businesses. As we delve into the realm of UV printing technology, we’ll uncover the transformative effects of UV DTF transfers on the personalized product market and the benefits they bring to businesses of all sizes.

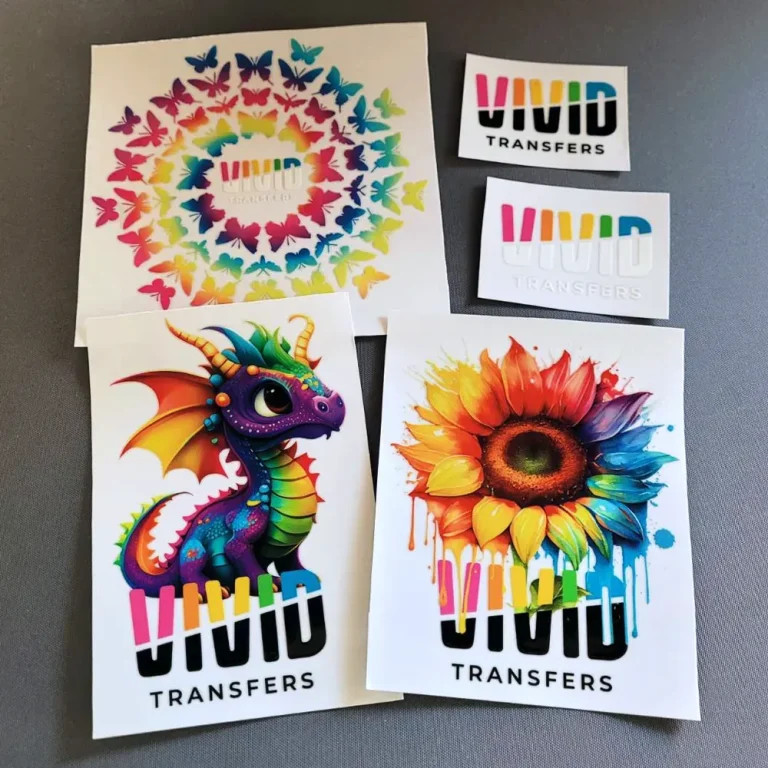

The realm of custom prints has been significantly enhanced by methods like UV Direct-to-Film (DTF) transfers, a process that merges cutting-edge technology with creative expression. These innovative techniques allow for unique artistry on various substrates, delivering high-resolution imagery that is long-lasting and visually striking. With the growing demand for bespoke items, enterprises that adopt this modern approach can tap into the personalized products market seamlessly. Moreover, UV-based printing solutions not only promise efficiency but also prioritize sustainable practices, reducing waste and harmful emissions. As the personal merchandise market continues to grow, the adoption of such advanced printing methods is more critical than ever.

Understanding UV DTF Transfers in Depth

UV DTF (Direct-to-Film) transfers have emerged as a revolutionary method in the realm of printing, offering a unique way to produce high-quality customized merchandise. This technology works by printing vivid designs onto a specially coated film, which is then cured using UV light, effectively locking in the colors and details of the design. This process ensures that the final product boasts exceptional durability and vibrancy, qualities that resonate well with businesses aiming to stand out in a saturated market.

Unlike traditional transfer methods, which often lead to peeling and fading after multiple washes, UV DTF transfers provide a more resilient solution. The adhesion of the ink is enhanced through the UV curing process, which not only accelerates production times but also minimizes the risk of errors, leading to cost-effective printing solutions. By embracing this technology, companies can produce personalized products that meet the diverse needs of their customers, all while maintaining a commitment to quality.

The Cost-Effective Benefits of UV DTF Transfers

One of the major advantages of adopting UV DTF transfer technology is its cost-effectiveness. Traditional printing methods often come with hefty upfront costs associated with machinery, setup, and a prolonged production timeline. On the other hand, UV DTF transfers require fewer materials and significantly reduce wastage during the printing process. This makes it an attractive proposition for small to medium enterprises that are looking to produce high-quality, customized items without breaking the bank.

Furthermore, UV DTF technology allows for smaller batch productions, which is ideal for businesses that want to test the waters before committing to larger orders. This flexibility means that brands can quickly adapt to changing market trends and customer preferences, maintaining a competitive edge. The ability to produce personalized products affordably not only enhances customer satisfaction but also encourages businesses to experiment with innovative designs and offers.

Customization at Its Finest with UV DTF Transfers

The modern consumer craves individuality and personalization, and UV DTF transfers are paving the way for businesses to fulfill these desires. With this technology, companies can offer a plethora of custom options, from personalized apparel to customized promotional materials that truly resonate with the target audience. The precision and versatility of UV printing technology make it possible to produce intricate designs and vibrant colors that capture the essence of personalization.

This level of customization not only satisfies the growing demand for unique items but also empowers businesses to engage with their clients on a deeper level. Customers are more likely to purchase merchandise that reflects their personality or interests, and UV DTF enables companies to provide tailored products that enhance brand loyalty. As a result, businesses can diversify their offerings, ensuring they are well-positioned to meet the demands of a dynamic marketplace.

Sustainable Printing Solutions: A Priority for Businesses

As environmental concerns continue to grow among consumers, businesses are seeking sustainable printing alternatives. UV DTF transfers stand out as a responsible printing solution due to their lower emissions of volatile organic compounds (VOCs) compared to conventional inks. This positive environmental impact addresses the increasing consumer preference for sustainable and eco-friendly products, making UV DTF transfers an appealing choice for brands that prioritize sustainability.

By investing in UV DTF technology, businesses not only enhance their product offerings but also align themselves with the values of eco-conscious consumers. This alignment can significantly boost brand reputation and affinity, leading to increased customer loyalty and sales. As the demand for sustainable products rises, companies that utilize UV printing technology will likely see a surge in their market position, ultimately fostering a healthier planet while satisfying consumer expectations.

Market Growth Trends in Customized Merchandise

The market for personalized merchandise is on a robust growth trajectory, largely driven by advancements in UV DTF transfer technology. As businesses become aware of the advantages that UV printing offers—such as production speed, durability, and customization flexibility—they are eagerly adopting this innovative technology to keep up with evolving consumer demands. With consumers gravitating towards unique products, UV DTF holds the potential to lead the industry toward new heights.

Forecasts suggest that brands integrating UV DTF transfers into their production processes will capture a significant share of the customized merchandise marketplace. As technology continues to evolve, businesses will be better equipped to meet the needs of consumers craving personalized items, subsequently driving further growth. The seamless combination of high-quality printing and customization capabilities ensures that companies adopting this technology are not only meeting market demands but also setting themselves up for long-term success.

User-Friendly Operations with UV DTF Technology

One of the standout features of UV DTF technology is its user-friendly operation, making it accessible to a wide range of businesses, regardless of their technical expertise. Modern UV printers are designed with intuitive interfaces that streamline the printing process, allowing operators to produce high-quality prints with minimal training. This ease of use helps businesses increase their productivity while fulfilling customer orders efficiently, reducing turnaround times significantly.

This user-friendliness eliminates barriers for small business owners who may lack extensive experience in printing technology. By simplifying the printing process, UV DTF empowers entrepreneurs to focus on creativity and design rather than the technical intricacies of printing. Consequently, businesses can diversify their product offerings and adapt quickly to market demands, further enhancing their competitive edge in a fast-evolving landscape.

Frequently Asked Questions

What are the benefits of using UV DTF transfers for customized merchandise?

UV DTF transfers provide several benefits for customized merchandise, including high-quality, vibrant prints and durable results. They allow for quick production times and lower setup costs, making them ideal for businesses of all sizes. In addition, UV DTF transfers enable businesses to create a wide variety of personalized products while also being environmentally friendly due to reduced VOC emissions.

How does UV printing technology enhance the quality of personalized products?

UV printing technology, used in UV DTF transfers, enhances the quality of personalized products by curing inks instantly. This results in sharp, high-resolution images and vibrant colors on various surfaces, including textiles and metals. The ability to print intricate designs with detail makes UV DTF an excellent choice for businesses looking to deliver standout custom merchandise.

Are UV DTF transfers a sustainable printing solution?

Yes, UV DTF transfers are considered a sustainable printing solution. They utilize UV inks that generate fewer volatile organic compounds (VOCs) compared to traditional inks, reducing harmful emissions. This eco-friendliness aligns with the increasing demand for sustainable products among consumers, making UV DTF an attractive option for environmentally-conscious businesses.

Can UV DTF transfers be used on different surfaces for customized products?

Absolutely! UV DTF transfers are versatile and can be used on a variety of surfaces, including plastics, metals, and textiles. This capability allows businesses to create customized products ranging from personalized apparel to promotional items, catering to the diverse needs of different market sectors.

What makes UV DTF transfers a cost-effective option for businesses?

UV DTF transfers are cost-effective because they reduce waste and lower setup costs compared to conventional printing methods. This technology allows businesses to produce smaller batches without significant financial risk, making it easier for them to adapt to changing market demands while minimizing upfront investments.

How user-friendly are UV DTF transfer technologies for businesses?

UV DTF transfer technologies are designed to be user-friendly, featuring intuitive interfaces that simplify operation. This means that businesses do not need extensive technical experience to produce high-quality prints, which increases productivity and enables faster order fulfillment for personalized products.

| Key Points | Details |

|---|---|

| Introduction to UV DTF Transfers | UV Direct-to-Film (DTF) transfers revolutionize the customized merchandise market through advanced printing technology. |

| What Are UV DTF Transfers? | A printing process where designs are printed onto a film and transferred onto surfaces with UV light, curing ink instantly for vibrant prints. |

| Technological Advancements | Sophisticated printers that can create high-resolution graphics on various surfaces, streamlining production for diverse business sectors. |

| Cost-Effectiveness | Reduced setup costs and waste, making it ideal for small to medium enterprises to produce flexible order sizes. |

| Customization Flexibility | Enables the production of unique, personalized items catering to individual consumer preferences. |

| Sustainability Concerns | More eco-friendly with fewer VOC emissions, responding to the growing demand for sustainable products. |

| Market Growth Trends | Projected significant growth in the personalized merchandise market driven by UV DTF technology. |

| User-Friendly Operations | New UV DTF printers feature intuitive interfaces, increasing accessibility for various businesses. |

Summary

UV DTF transfers are revolutionizing the world of customized merchandise by offering businesses a reliable and innovative printing solution. This technology not only ensures high-quality, vibrant prints but also addresses consumer demand for personalization and sustainability. By minimizing waste and reducing costs, UV DTF empowers companies to respond quickly to market changes while maintaining exceptional print quality. As this technology continues to evolve, it unlocks new opportunities, enabling businesses to stay ahead in the competitive market of custom products.