UV DTF transfers are revolutionizing the custom apparel landscape with their innovative printing technology designed for creating vibrant and detailed designs on various materials. This cutting-edge method is quickly becoming the go-to option for businesses seeking to produce personalized clothing that stands out in a competitive market. With an emphasis on quality and durability, UV DTF transfers not only meet the demands of modern consumers but also align with the rising interest in sustainable fashion practices. As small batch production becomes more popular, this technology facilitates precise customization without sacrificing efficiency or environmental consciousness. In this article, we will explore how UV DTF transfers are shaping the future of custom apparel and the multiple benefits they offer to brands and consumers alike.

The landscape of printing for personalized fashion is evolving, and one of the standout methods leading this change is UV Direct to Film (DTF) printing. This advanced technique allows for high-quality, eye-catching designs that can be applied to a wide range of materials, making it a perfect fit for the demands of custom clothing production. As the industry shifts towards more sustainable practices, alternative printing methods like UV DTF are gaining traction due to their low environmental impact and quick turnaround times. Furthermore, the ability to create small batch productions makes this technology particularly attractive to brands looking to meet the diverse needs of their customer base. In this discussion, we will delve into the impact of UV DTF transfers on the custom apparel sector and the transformative benefits they bring to both businesses and consumers.

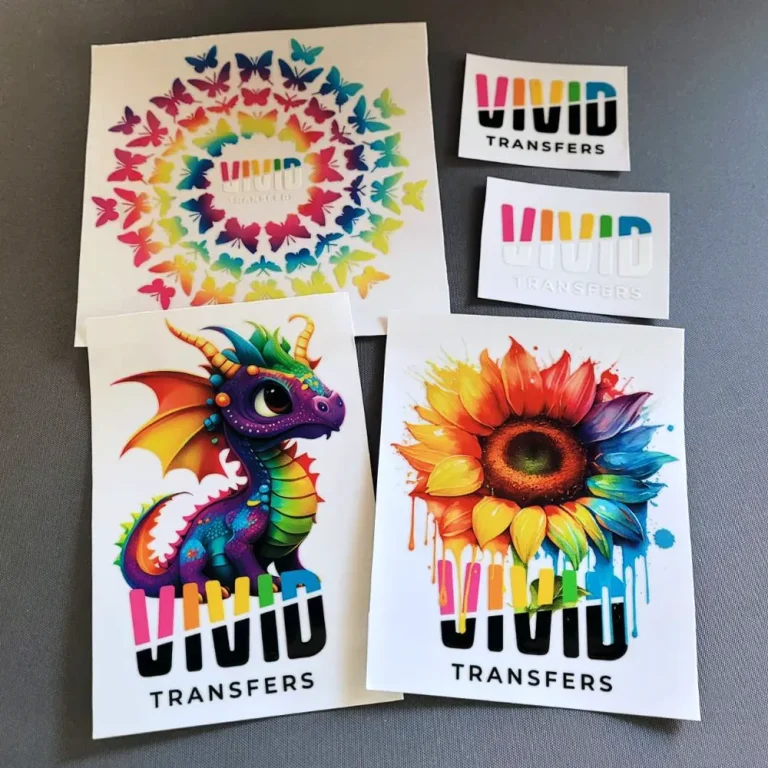

Introduction to UV DTF Transfers

UV DTF (Direct to Film) transfers are revolutionizing the custom apparel landscape by providing a unique solution for creating personalized clothing. This innovative printing technology utilizes UV-cured inks, allowing intricate designs to be printed on a special film which can be applied to a range of materials. With this method, businesses can achieve vibrant colors that are not only visually appealing but also incredibly durable, standing the test of time against elements like washing and exposure to sunlight.

Moreover, the use of UV DTF transfers signifies a shift in how apparel is produced, particularly in the realm of small batch production. As consumer preferences evolve towards more personalized apparel, UV DTF allows for quick turnaround times, accommodating the bespoke demands of modern shoppers. This can lead to higher customer satisfaction, proving that such advancements in printing technology are not just beneficial for manufacturers but also enhance the overall consumer experience.

Key Advantages of UV DTF Printing Technology

One of the most significant advantages of UV DTF printing technology is its unparalleled quality and longevity. As opposed to traditional printing methods, UV DTF prints are resistant to cracking, fading, and peeling, which makes them ideal for clothing that is meant to endure frequent use and washing. This durability is essential for brands looking to create lasting impressions with their customers, as it directly correlates with product quality and consumer satisfaction.

In addition to its durability, UV DTF technology streamlines the production process. Unlike conventional methods that may require pre-treatment, UV DTF simplifies setup and preparation, significantly reducing production times. This efficiency is particularly advantageous for businesses that thrive on quick turnaround times and custom orders, enabling them to meet the rising demands of a dynamic market. The result is a more agile and responsive manufacturing approach that aligns with contemporary retail needs.

Sustainability and Eco-Friendly Practices in Custom Apparel

As sustainability becomes an increasingly important factor in consumer decision-making, UV DTF transfers offer a compelling solution for eco-conscious apparel brands. The inks used in UV DTF printing have lower volatile organic compound (VOC) emissions compared to traditional printing methods, allowing companies to market themselves as environmentally friendly. By adopting UV DTF, brands can focus on sustainable production practices, engaging consumers who prioritize eco-friendly options.

Furthermore, the shift toward sustainable fashion is bolstered by the ability to produce small batch runs without excessive waste. UV DTF’s capacity for on-demand printing means that businesses can create personalized clothing items tailored to specific consumer preferences, minimizing overproduction and unnecessary inventory. As the apparel industry continues to navigate the challenges of environmental impact, technologies like UV DTF are becoming essential for fostering a sustainable future.

The Demand for Personalized Apparel

There has been a marked increase in consumer demand for personalized apparel, with individuals seeking unique items that reflect their personal style. UV DTF transfers are perfectly positioned to meet this trend, allowing brands to offer customization options without sacrificing quality. This capability extends to a wide range of garments, enabling businesses to cater to niche markets that prioritize distinctiveness in fashion.

The ability to produce customized apparel on a small scale fosters creativity and innovation, allowing brands to explore diverse design choices. This trend not only satisfies modern consumers’ desires for individuality but also opens new avenues for marketing and brand identity. By tapping into this demand, companies can build stronger connections with their customers, ultimately resulting in heightened loyalty and recurring sales.

Emerging Market Trends for Custom Apparel

Emerging market trends in the custom apparel sector highlight the increasing accessibility of printing technology like UV DTF. As the cost of UV DTF printers decreases, more small and medium-sized businesses can invest in these innovative solutions. This democratization of technology allows for a broader spectrum of creativity within the industry, enabling new entrepreneurs to enter the market with unique offerings that capitalize on the benefits of UV DTF.

Additionally, the rise of e-commerce and online customization platforms has transformed how apparel is marketed and sold. Brands are leveraging UV DTF printing technology to provide online design tools that empower customers to create their own personalized items from the comfort of home. This trend not only caters to individual preferences but also aligns with the growing demand for convenience in shopping experiences, thus reshaping the custom apparel industry.

The Future of Custom Apparel with UV DTF Transfers

Looking ahead, the future of custom apparel seems promising with the continued evolution of UV DTF technology. Ongoing advancements in ink formulations, production speeds, and printing capabilities will only enhance the effectiveness of this method. As companies adapt to these changes, the potential for innovative designs and greater customizability will expand, positioning UV DTF at the forefront of the apparel industry.

As brands strive to stay competitive in an ever-changing market, embracing technologies like UV DTF will prove to be a crucial strategy. Companies that invest in this technology can not only improve their product offerings but also align themselves with consumer trends that prioritize personalization and sustainability. This alignment will be key for brands aiming for long-term success in the thriving world of custom apparel.

Frequently Asked Questions

What are UV DTF transfers and how do they enhance custom apparel?

UV DTF (Direct to Film) transfers are a modern printing technology that utilizes UV-cured inks to create vibrant, intricate designs on a film for application on various materials, including fabrics. This method enhances custom apparel by providing high durability, rich colors, and detailed images, making it ideal for personalized clothing.

How do UV DTF transfers compare to traditional custom apparel printing methods?

Unlike traditional custom apparel printing methods like screen printing, UV DTF transfers offer superior durability, preventing fading and cracking over time. Additionally, UV DTF simplifies production with no pre-treatment required, allowing for quicker and more efficient turnaround on small batch production orders.

What role does UV DTF technology play in the sustainable fashion movement?

UV DTF technology contributes to sustainable fashion by using eco-friendly inks with lower VOC emissions than conventional printing options. This aligns with consumer demand for sustainable products, making it an attractive choice for businesses looking to reduce environmental impact while still producing high-quality custom apparel.

Can UV DTF transfers accommodate personalized clothing needs in small batch production?

Yes, UV DTF transfers are specifically designed for small batch production, allowing businesses to create custom designs on demand. This flexibility meets the growing consumer demand for personalized clothing while maintaining high quality and efficiency in the production process.

What are the market trends driving the adoption of UV DTF transfers in custom apparel?

Key market trends driving the adoption of UV DTF transfers include a rising consumer preference for personalized apparel and the increased accessibility of affordable UV DTF printers for small to medium businesses. This technological democratization promotes creative solutions and enhances production capabilities in the custom apparel sector.

What future advancements can we expect with UV DTF transfer technology?

Future advancements in UV DTF transfer technology may include innovations in ink formulation, production speed, and application versatility. These improvements will likely enhance customization options and efficiency, potentially expanding UV DTF’s use beyond just custom apparel into various industries.

| Key Aspect | Details |

|---|---|

| Understanding UV DTF Transfers | A modern printing method using UV-cured inks on various materials that delivers vibrant colors and durable images. |

| Advantages of UV DTF Transfers | 1. **Quality and Durability**: Resistant to fading and cracking, ideal for long-term use. 2. **Streamlined Production**: Simplifies production and reduces setup times for quicker turnarounds. 3. **Sustainability**: Lower VOC emissions, appealing to eco-conscious consumers. |

| Market Trends Influencing UV DTF Transfers | 1. **Personalized Apparel Demand**: Growing preference for unique, customized items. 2. **Technology Accessibility**: Affordable UV DTF printers for all business sizes, encouraging widespread use. |

| Future Prospects of UV DTF Transfers | Anticipated innovations will improve customization options and overall production effectiveness, broadening applications beyond fashion. |

Summary

UV DTF Transfers are revolutionizing the custom apparel industry by merging personalization with advanced printing technologies. This innovative approach not only caters to the growing demand for unique and durable designs but also aligns with sustainable practices—a crucial factor for modern consumers. As UV DTF technology continues to evolve, it will reshape the future landscape of apparel production, allowing businesses to thrive in a competitive market by harnessing its vast potential.