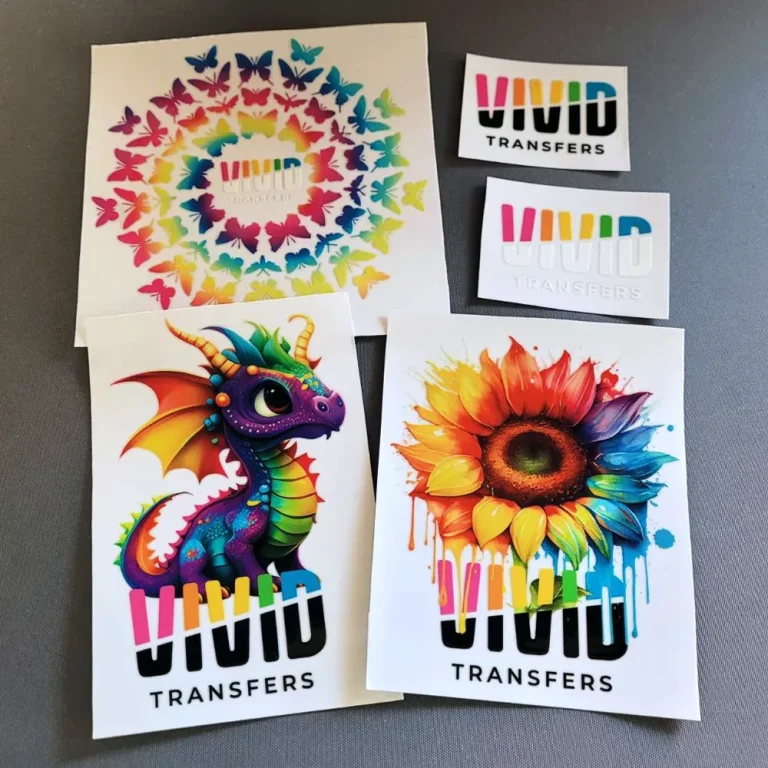

UV DTF Transfers are revolutionizing the realm of graphic design by providing an advanced printing solution that seamlessly combines creativity and efficiency. This innovative method utilizes ultraviolet inks to create high-quality, vibrant transfers suitable for a wide variety of substrates, from textiles to metals. As businesses and designers increasingly seek custom printing solutions, UV DTF transfers emerge as a frontrunner, meeting demands for detail and durability in apparel design. Moreover, this sustainable printing technology minimizes environmental impact, aligning with the growing preference for eco-conscious practices in the industry. In this blog, we will delve into the capabilities of UV DTF transfers and their significant role in shaping the future of graphic design.

Exploring UV Direct to Film transfers reveals an intersection of art and technology that is reshaping custom graphics. Also known as UV DTF printing, this process allows for intricate designs to be printed directly onto transfer films, which can then be heat-applied to various materials. By leveraging cutting-edge techniques in direct to film printing, designers can experiment with diverse textures and surfaces, pushing the boundaries of traditional apparel design. The upgraded capabilities of UV transfer printing not only foster creativity but also enhance the speed and efficiency of production. As the demand for personalized items rises, this technique presents a compelling solution for businesses aiming to deliver unique, high-quality products.

Understanding UV DTF Transfers

UV DTF transfers represent a groundbreaking method in the realm of graphic design, characterized by the application of UV-curable inks on films. This technology allows for a broad range of surfaces to be printed, including wood, glass, metals, and, notably, textiles. Graphic designers benefit from the enhanced capabilities offered by UV DTF printing, empowering them to explore their creativity with the assurance of high-quality results. As direct to film printing technology continues to improve, designers can anticipate increasingly diverse applications and finishes that cater to modern aesthetic demands.

The appeal of UV DTF transfers extends beyond mere printing capabilities; it also encompasses the speed and efficiency of the production process. By streamlining workflows and reducing turnaround times, this technique enables designers to rapidly bring their creative visions to life. Thus, UV DTF transfers simplify the process of custom printing solutions, ideal for businesses looking to address growing consumer demands for unique and personalized items.

The Versatility of UV DTF Transfers in Graphic Design

One of the most prominent advantages of UV DTF transfers is their versatility. This innovative printing method allows graphic designers to work across various media, all while maintaining exceptional print quality. Whether creating promotional merchandise, durable apparel, or bespoke interior décor, the application of UV DTF technology offers endless design possibilities. This newfound flexibility has inspired designers to push their limits, fostering an environment where creativity thrives and innovative designs flourish.

Furthermore, the ability to transfer intricate designs onto diverse substrates opens up greater opportunities for graphic designers. From fashion items that resonate with personal style to captivating merchandise for events and promotions, UV DTF transfers seamlessly adapt to different market demands. This adaptability is particularly relevant in today’s consumer climate, where uniqueness and customization are increasingly prioritized.

Sustainability and Environmental Impact of UV DTF Printing

The move towards sustainable printing technology is more significant than ever, as consumers become increasingly aware of environmental issues. One of the noteworthy benefits of UV DTF transfers is their reduced environmental impact compared to traditional printing methods. Conventional printing often involves the use of harmful solvents and generates high levels of waste, whereas UV DTF printing utilizes eco-friendly UV inks that minimize volatile organic compound (VOC) emissions.

Moreover, the DTF process requires fewer resources and generates less waste overall. By implementing sustainable practices in their printing operations, graphic designers and businesses alike can promote an eco-conscious approach while appealing to environmentally-minded consumers. UV DTF transfers embody this commitment to sustainability, positioning designers as forward-thinking innovators in the graphic design industry.

Technological Innovations Driving UV DTF Growth

Advancements in technology play a crucial role in the ongoing evolution of UV DTF printing. New printer models are being developed that offer faster printing speeds, higher print resolutions, and superior color accuracy. These technological improvements not only empower graphic designers to enhance the quality of their work but also enable them to meet the ever-increasing demands of their clientele efficiently. As the rate of innovation accelerates, these advancements solidify UV DTF transfers as a leader in modern printing techniques.

Additionally, the evolution of UV LED technology has considerably reduced curing times. This efficiency allows designers to complete projects faster, translating into improved customer service and satisfaction. Consequently, businesses can handle larger volumes of orders without sacrificing quality, further establishing UV DTF printing as an essential tool in the graphic design landscape.

Market Trends: The Growing Demand for Customization

The appetite for customized products has surged in recent years, particularly in the apparel sector. This consumer trend is a driving force behind the growing market for UV DTF transfers. Businesses are eager to leverage this technology, enabling them to offer an extensive range of personalized options tailored to individual preferences. In a market saturated with generic products, companies that embrace UV DTF printing can significantly differentiate themselves, tapping into the lucrative customization niche.

Furthermore, this demand for personalized products translates into substantial growth opportunities for graphic designers. They can innovate and create unique designs that resonate with consumers while maintaining the versatility offered by UV DTF technology. This customization trend not only fosters creativity but also encourages closer connections between businesses and their customers, cultivating brand loyalty and engagement through tailored experiences.

Expanding Applications of UV DTF Transfers Across Industries

UV DTF transfers not only impact the graphic design sector but also find applications in numerous industries. From home décor to signage and promotional products, the versatility of this printing technology allows for a wide array of creations. Businesses in various sectors have begun adopting UV DTF printing to produce distinctive designs that appeal to their audiences, illustrating the potential of this technology to drive innovation across multiple fields.

For instance, in the interior design industry, professionals are utilizing UV DTF transfers to produce customized wall art and decorative pieces that enhance residential and commercial spaces. In the realm of promotional products, companies leverage UV DTF printing to create eye-catching items that leave a lasting impression on consumers. As the uses for UV DTF technology continue to expand, so too do the opportunities for graphic designers to engage with diverse markets and meet unique consumer needs.

Frequently Asked Questions

What are the advantages of using UV DTF transfers in graphic design?

UV DTF transfers offer numerous advantages in graphic design, including enhanced print quality, versatility across various materials, and a commitment to sustainability. By utilizing UV-curable inks, this method allows for stunning and vibrant designs that adhere effectively to textiles, wood, metal, and glass, making it a favored choice among designers seeking innovative custom printing solutions.

How does UV DTF printing contribute to sustainable printing technology?

UV DTF printing significantly contributes to sustainable printing technology by using UV inks that emit fewer volatile organic compounds (VOCs) compared to traditional inks. This eco-friendly approach minimizes waste and avoids the need for harmful pre-treatments or coatings, aligning with the growing consumer demand for environmentally responsible practices in the graphic design and custom printing industry.

Can UV DTF transfers be used for apparel design?

Absolutely! UV DTF transfers are particularly well-suited for apparel design as they provide high-quality, durable prints that withstand everyday wear. This technology allows designers to create intricate and vibrant apparel, catering to the growing demand for personalized and custom clothing options. Additionally, UV DTF’s versatility means you can apply designs to various fabric types, enhancing creative possibilities.

What recent advancements have improved UV DTF transfer technology?

Recent advancements in UV DTF transfer technology include faster printing speeds, higher resolution outputs, and enhanced color gamuts due to new printer models and UV LED technology. These innovations not only boost efficiency in production but also yield superior quality prints, allowing graphic designers to meet high consumer expectations while shortening production times.

What industries can benefit from UV DTF transfers beyond graphic design?

Beyond graphic design, industries such as interior decoration, signage, and promotional merchandise can greatly benefit from UV DTF transfers. This printing method allows businesses in these sectors to create unique and customizable products, ranging from personalized wall décor to vibrant signs, enabling them to stand out in saturated markets and meet the diverse needs of their audiences.

Is UV DTF printing a good option for small businesses in custom printing solutions?

Yes, UV DTF printing is an excellent option for small businesses seeking custom printing solutions. Its ability to produce high-quality, customizable designs efficiently positions small brands to cater to specific consumer demands, enhancing their marketability. The technology also allows for quick turnaround times on orders, supporting the growth of small businesses in the competitive custom printing landscape.

| Key Point | Description |

|---|---|

| What are UV DTF Transfers? | A digital printing technology using UV-curable inks to print designs onto film, which are then transferred to various substrates under heat and pressure. |

| Enhanced Versatility | Allows applications on a wide range of materials, enabling intricate designs that cater to diverse consumer preferences. |

| Commitment to Sustainability | Uses UV inks which emit fewer VOCs compared to traditional inks, minimizing waste and aligning with eco-friendly practices. |

| Technological Advancements | New UV printers are faster and produce higher quality prints; improvements in LED curing times enhance efficiency. |

| Market Growth and Customization | Growing demand for customized products is driving the expansion of the UV DTF market, particularly in the apparel industry. |

| Applications Across Industries | Suitable for a variety of applications, including interior design and promotional merchandise, allowing for broad market appeal. |

Summary

UV DTF Transfers are transforming the graphic design landscape by offering innovative solutions that cater to modern demands. This technology stands out for its versatility, enabling designers to print high-quality designs on a wide array of materials while adhering to sustainable practices. As the market for UV DTF transfers grows, we can expect to see it shape future design trends, enhancing creativity and customization in various industries. With its commitment to eco-friendly solutions and technological advancements, UV DTF transfers promise a bright future for graphic design.