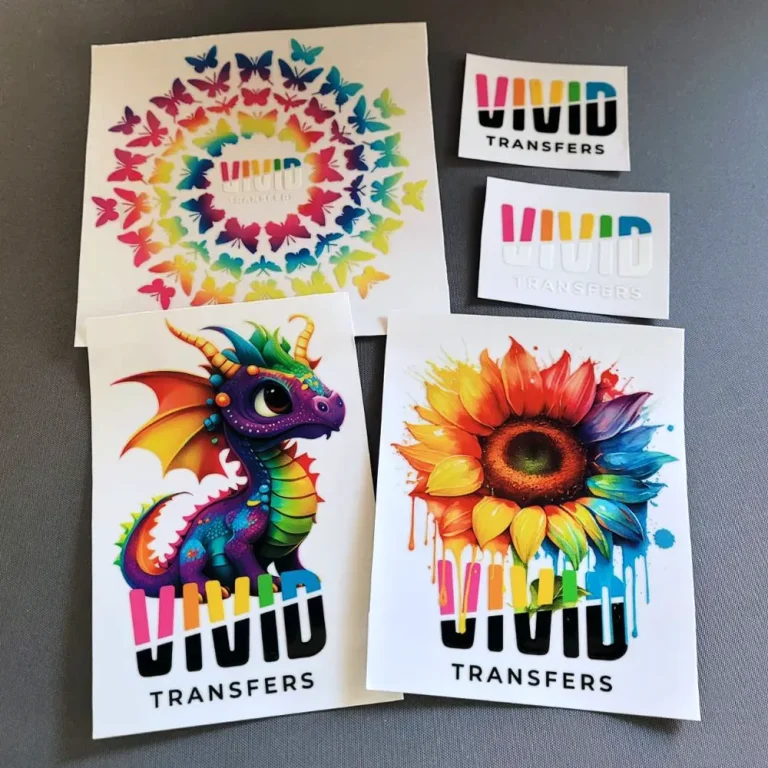

In the realm of custom printing, UV DTF transfers have revolutionized the way designs come to life, offering an exciting blend of vibrancy and durability. This innovative process, known as UV Direct-to-Film transfers, utilizes advanced ultraviolet technology to produce high-resolution prints that stand out on various materials. The adaptability of UV DTF transfers makes them ideal for applications in textiles, promotional items, and interior décor, paving the way for endless creative possibilities. With their capability to deliver intricate designs and bold colors, UV DTF transfers are quickly becoming the go-to choice in the custom printing world. Discover how this cutting-edge technique can elevate your projects while providing the durability in printing that consumers demand.

Exploring the intricacies of direct-to-film (DTF) printing unveils a transformative approach to custom design applications. Often referred to as UV Direct-to-Film technology, this printing method employs ultraviolet curing to produce vibrant and high-quality images that adhere remarkably well to diverse substrates. Emphasizing its versatility, the DTF transfer process allows businesses to showcase their branding on apparel, promotional products, and more with striking finesse. This technology not only enhances aesthetic appeal but also ensures longevity, making it a preferred option among those seeking exceptional custom printing solutions. By leveraging the capabilities of UV printing combined with DTF methods, creators can achieve remarkable results that cater to the modern market’s demand for durability and customization.

Understanding the Importance of UV Printing in Today’s Market

UV printing has revolutionized the way businesses approach custom printing by delivering high-quality results with a quicker turnaround. The use of ultraviolet light accelerates the whole printing process, which is particularly beneficial in commercial settings where time is often of the essence. This technology not only enhances efficiency but also streamlines workflows, allowing for rapid production of marketing materials, apparel, and packaging. Consequently, businesses that adopt UV printing find they can meet the increasing demands for quick service without sacrificing quality.

Moreover, UV printing’s ability to produce vibrant colors that stand the test of time adds substantial value to final products. Unlike traditional printing methods, which may cause images to fade or become dull over time, UV-printed items resist wear and tear. This characteristic is critical for industries where product longevity is vital, such as in fashion and promotional items. As a result, UV printing is becoming a preferred choice, enabling brands to maintain their image and consumer trust through high-quality, long-lasting products.

The Unique Benefits of UV DTF Transfers

UV DTF transfers embody a unique synergy of advanced technology and creative freedom. One of the primary benefits is their ability to achieve unparalleled durability in printing. Products adorned with UV DTF transfers are less prone to fading, cracking, or scratching, which enhances their usability across various applications. This durability makes them ideal for items that undergo frequent handling or are exposed to outdoor conditions, ensuring that designs remain striking over time.

Additionally, UV DTF transfers excel in versatility, allowing companies to print on a diverse range of materials, including fabrics, metals, and rigid surfaces. This flexibility opens up numerous opportunities for customization in industries like fashion, home decor, and promotional products. By utilizing UV DTF technology, businesses can cater to specific consumer needs, creating tailored items that resonate with their target audience, ultimately driving sales and brand loyalty.

Exploring the DTF Transfer Process

The DTF transfer process is a multi-step journey that begins with meticulous design creation, utilizing advanced graphic software to bring concepts to life. Artists must ensure that images are high-resolution and optimized for UV printing, as the intricacies of design play a significant role in ensuring the quality of the final product. Through thoughtful design, the potential for eye-catching, vivid prints is unlocked, setting the stage for a successful transfer.

Once the design is finalized, it is printed using specialized UV DTF printers that employ UV-curable inks. These inks are instantly cured during the printing process, yielding vibrant and detailed outcomes that cater to modern consumer tastes. This rapid turnaround is particularly advantageous in today’s fast-paced market, allowing businesses to meet customer demands without compromising quality. Each stage of this process is critical in ensuring the seamless transition from creativity to final product.

Visual Appeal and Longevity: Key Features of UV DTF Transfers

The visual appeal of products created with UV DTF transfers cannot be understated. The combination of UV cured inks and highly detailed designs ensures that each print is not only striking but also true to the artists’ vision, maintaining the concept’s integrity in the physical form. This visual quality is a major selling point for businesses looking to stand out in crowded markets, as consumers overwhelmingly favor products that boast vivid imagery and uniqueness.

Additionally, longevity is a hallmark of UV DTF transfers, positioning them as a reliable choice for businesses who prioritize durability in their products. Items printed with this technology endure various forms of physical stress, such as washing and exposure to sunlight, better than those created with traditional methods. This capability allows brands to offer guarantees on product quality, enhancing customer satisfaction and encouraging repeat purchases.

Recent Innovations in UV DTF Technology

The landscape of UV DTF technology is continuously evolving, with recent innovations aimed at enhancing sustainability and production efficiency. Eco-friendly inks are making waves, emphasizing the industry’s commitment to reducing environmental impact while delivering high-quality prints. This shift is particularly appealing to eco-conscious consumers, who increasingly prioritize environmentally responsible products in their purchasing decisions.

Furthermore, new technological advancements are focused on maximizing output while minimizing waste, addressing the industry’s need for efficiency. For businesses, these developments mean reduced operational costs, which can ultimately translate into lower prices for consumers. As such, staying at the forefront of these innovations not only entails better products but also aligns companies with the growing consumer demand for sustainable practices.

Applications of UV DTF Technology Across Industries

The practical applications of UV DTF technology are extensive, impacting multiple industries from fashion to promotional products. In apparel, UV DTF allows for eye-catching prints on t-shirts, hats, and other clothing items, appealing greatly to consumers looking for individual expression through unique designs. This flexibility helps brands differentiate themselves in a marketplace saturated with similar offerings, thereby attracting a loyal customer base.

Furthermore, UV DTF technology shines in the realm of promotional products, where businesses can create customized merchandise such as mugs, phone cases, and tote bags. These products not only serve as effective marketing tools but also enable brands to foster connections with their clientele. The ability to print high-quality, compelling designs on a variety of substrates makes UV DTF transfers an indispensable resource for brands looking to elevate their promotional strategies.

Frequently Asked Questions

What are UV DTF transfers and how do they work in custom printing?

UV DTF transfers, or UV Direct-to-Film transfers, utilize ultraviolet light to cure special inks printed onto a film substrate. This film can then be transferred onto various materials, resulting in high-resolution, vibrant prints that are durable and resistant to fading, making them ideal for custom printing applications.

What advantages do UV DTF transfers offer over traditional printing methods?

UV DTF transfers provide several advantages over traditional printing methods, including higher color vibrancy, superior durability that resists cracking and fading, and the ability to adhere to a wide range of substrates like fabric, wood, and metal. These features make them a preferred choice for businesses seeking quality and efficiency in custom printing.

How does the DTF transfer process ensure the durability of prints?

The DTF transfer process enhances print durability through immediate UV curing of the inks as they are printed onto the film, followed by a heat application during transfer. This method ensures that inks bond securely to the substrate, resulting in prints that maintain their quality over time, even under exposure to washing and sunlight.

What types of materials can be used with UV DTF printing?

UV DTF printing is versatile and can be applied to a variety of materials including fabrics, metals, wood, glass, and plastics. This flexibility allows businesses to explore diverse applications from apparel to promotional items, catering to different market needs in custom printing.

What should I consider when choosing a printer for UV DTF transfers?

When selecting a UV DTF printer, consider factors like print speed, print width, and the variety of ink options available. Faster print speeds can reduce production time, while ensuring the printer can accommodate your substrate sizes and desired finishes is vital for achieving high-quality results.

Can UV DTF transfers be eco-friendly, and what recent innovations support this?

Yes, recent innovations in UV DTF transfer technology have led to the development of eco-friendly inks that reduce environmental impact. Many manufacturers are focusing on improving efficiency and minimizing waste, aligning with sustainability trends in the printing industry while maintaining high-quality output.

| Key Points | |

|---|---|

| UV DTF Technology | Utilizes UV light to cure inks on film for printing on various materials. |

| Advantages of UV DTF Printing | 1. Vibrant colors 2. High durability 3. Versatile adhesion |

| Process of UV DTF Transfer | 1. Design Creation 2. Printing with UV-curable inks 3. Transfer and curing 4. Quality control checks |

| Recent Developments | 1. Eco-friendly inks 2. Increased efficiency 3. Customizable options |

| Applications | 1. Apparel 2. Promotional products 3. Interior decor |

Summary

UV DTF transfers are revolutionizing the custom printing industry, offering a cutting-edge blend of technology and creativity. This innovative printing method allows for vibrant, durable prints that can adhere to a variety of materials, making it ideal for a wide range of applications. The process involves creating high-quality designs, printing with UV-curable inks, and confident transfer techniques that guarantee product longevity. As the market continues to embrace UV DTF transfers, the emphasis on sustainable practices and rapid customization will only grow, paving the way for a more dynamic and eco-friendly printing future.