UV DTF Transfers are revolutionizing the world of printing, providing endless possibilities for customizing various materials. With the integration of UV printing technology, digital transfer printing has become more efficient and vibrant, allowing designers to create stunning visuals on everything from custom apparel to promotional items. This innovative method involves a heat press application, ensuring that the transfer film adheres securely to the substrate, while UV inks guarantee long-lasting, brilliant colors. As businesses strive to meet diverse needs, UV DTF transfers offer an unmatched combination of quality and versatility that traditional methods simply can’t match. In this guide, we’ll explore the ins and outs of UV DTF transfers, covering everything you need to know to maximize your printing projects.

Also referred to as Direct to Film printing, UV DTF Transfers utilize cutting-edge technology for applying images to various surfaces with greater precision and durability. This method of digital transfer printing is gaining immense popularity among both professionals and hobbyists alike, enabling the production of high-quality custom apparel and merchandise. At its core, the process involves printing designs onto transfer films before they are heat pressed onto chosen materials, resulting in vibrant, fade-resistant prints. As advancements continue to shape the future of this printing technique, understanding the essentials of UV DTF can help creators explore their artistic potential fully. Join us as we delve deeper into the fascinating world of Direct to Film printing and uncover its many advantages.

Understanding UV DTF Transfers

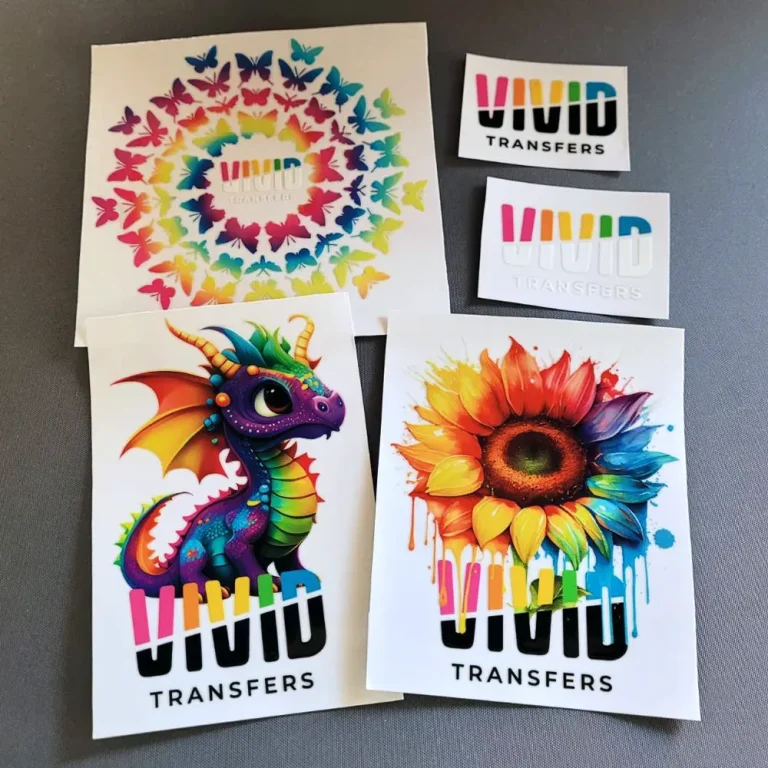

UV DTF Transfers, or Ultra Violet Direct to Film Transfers, represent a groundbreaking advancement in the realm of digital printing. This method involves transferring images onto a specially formulated film before applying them to various substrates, using a heat press to ensure a durable bond. Unlike traditional methods, UV DTF printing utilizes UV-curable inks which allow for enhanced durability, providing a rich color palette that often outshines screen printing and other techniques.

The versatility of UV DTF Transfers cannot be understated. This method can print on a diverse range of materials, from soft fabrics suitable for custom apparel to hard surfaces like plastics and metals. Such flexibility enables designers and manufacturers to create promotional items, decorative artwork, and fashion pieces, making UV DTF Transfers a go-to option for anyone looking to push creative boundaries.

Frequently Asked Questions

What is the process of UV DTF transfers in digital printing?

UV DTF transfers involve printing high-quality images onto a special transfer film using UV-cured inks. The printed film is then applied to a substrate using a heat press, allowing for vivid and durable prints on various materials such as custom apparel, plastic, and even metal.

What are the advantages of using UV printing technology for DTF transfers?

UV printing technology offers several advantages for DTF transfers, including vibrant colors that resist fading, exceptional durability against scratches and water, and versatility across different surfaces. This makes UV DTF a preferred choice when creating custom apparel and promotional products.

Do I need special equipment for UV DTF transfers?

Yes, specific equipment is essential for UV DTF transfers, including a UV DTF printer that supports UV inks, a reliable heat press for transferring images, transfer films designed for UV applications, and graphic design software for preparing print files.

How do UV DTF transfers compare to traditional printing methods like screen printing?

UV DTF transfers are often more efficient than traditional screen printing since they allow for faster production times and the ability to produce complex and colorful designs with ease. Additionally, they offer superior durability and vibrancy, making them suitable for both indoor and outdoor use.

What are the best practices for achieving high-quality UV DTF transfers?

To ensure successful UV DTF transfers, it’s important to prepare surfaces properly by cleaning them to enhance ink adhesion, adjust printer settings according to the substrate and ink type, and conduct test prints to fine-tune parameters for optimal results.

Are there any recent developments in UV DTF technology?

Recent advancements in UV DTF technology include enhanced ink formulations for better adhesion, improved printing equipment that increases speed and lowers costs, and the introduction of eco-friendly inks that align with sustainability efforts in the printing industry.

| Key Features and Benefits of UV DTF Transfers |

|---|

| Versatility: Prints on various materials including fabrics, plastics, and metals. |

| Vibrant Colors: UV inks create bright, fade-resistant colors suitable for sunlight exposure. |

| Durability: Finished prints are scratch, water, and UV resistant, ideal for various applications. |

| Efficiency: Faster production times compared to traditional methods like screen printing. |

Summary

UV DTF Transfers have emerged as a revolutionary technique in the digital printing world, offering remarkable versatility and durability. Ideal for those looking to create vibrant designs on a variety of surfaces, this method utilizes advanced UV-curable inks that not only deliver striking colors but also boast longevity. The development of newer equipment and sustainable practices further enhances the popularity of UV DTF Transfers, making it an attractive option for both beginners and seasoned professionals. The accessibility of resources such as tutorials and industry workshops simplifies the learning curve, encouraging a greater adoption of this innovative printing technology.