In an era where branding is paramount to business success, **UV DTF transfers** (Direct to Film) are redefining how companies convey their unique identities. This cutting-edge technology harnesses UV printing technology to create vibrant, high-quality designs that elevate brands above the competition. By allowing businesses to explore custom branding solutions across various materials, UV DTF transforms traditional transfer printing into a versatile and impactful branding strategy. Emphasizing sustainability, this innovative approach minimizes waste and promotes eco-friendly practices, aligning brands with contemporary consumer values. As we delve deeper into the realm of UV DTF transfers, it becomes clear that they are not just a trend but a transformative force in modern branding.

Exploring the world of **UV DTF printing**, often referred to as Direct to Film technology, reveals a stunning advancement in the branding landscape. This innovative method utilizes ultraviolet curing processes to achieve exceptionally detailed and colorful prints on multiple substrates, making it a popular choice for businesses seeking to enhance visual impact. Known for its flexibility, UV DTF allows for seamless integration in custom branding initiatives, which is essential for modern marketing strategies. Moreover, this approach underscores a commitment to sustainable printing practices, addressing the increasing demand for environmentally conscious production. As brands look towards dynamic and personalized solutions, UV DTF remains at the forefront, offering unmatched quality and versatility.

Understanding the Basics of UV DTF Transfers

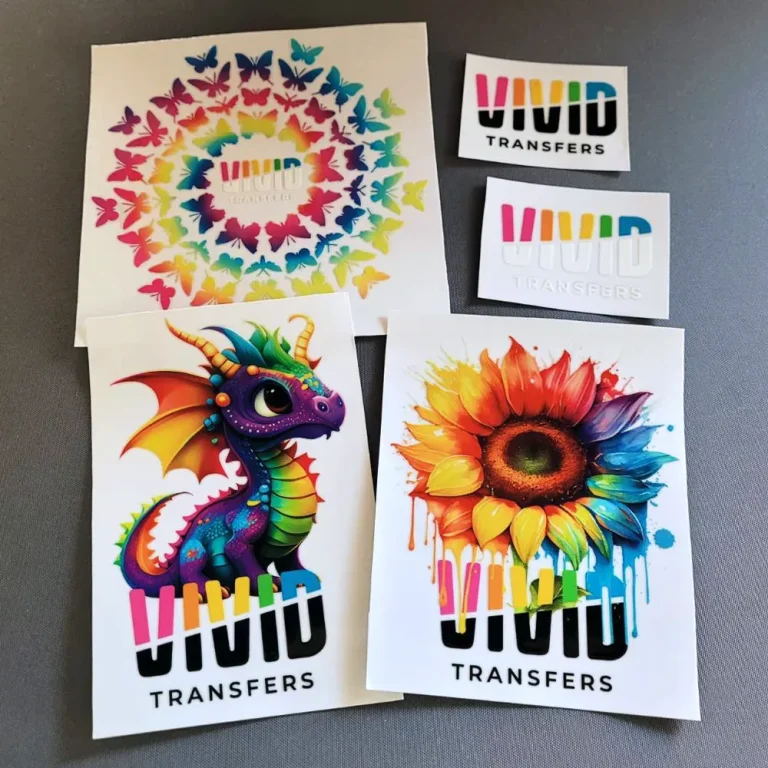

UV DTF transfers, or Ultraviolet Direct to Film transfers, represent a significant leap in printing technology. This technique employs UV light to cure ink directly onto the film, resulting in vibrant, long-lasting prints that can be applied to a wide variety of surfaces. The ability to print on different substrates not only expands creative possibilities but also enhances the flexibility of branding initiatives. By employing UV DTF, brands can achieve stunning, detailed designs that stand out in a crowded marketplace.

The technology behind UV DTF is particularly compelling due to its rapid curing process. Unlike traditional printing methods that may require drying time, UV DTF prints are instantly ready for application. This efficiency leads to quicker turnaround times and more agile responses to market changes, vital for brands that must adapt and innovate continuously. As a result, companies can execute their branding strategies with enhanced speed and precision, refining their marketing efforts to better align with audience expectations.

The Impact of UV DTF Transfers on Brand Identity

Brand identity is critical for any organization aiming to resonate with consumers. UV DTF transfers play a pivotal role in crafting a distinctive brand image. Through high-resolution, colorful designs, businesses can effectively communicate their unique selling propositions (USPs) and core values to customers. This enhanced visual appeal can significantly elevate brand perception, leading consumers to associate quality and creativity with the brand. Ultimately, UV DTF technology serves as a powerful tool in reinforcing brand messaging and identity.

Moreover, the versatility of UV DTF allows brands to apply their visual identity across various marketing collateral, from promotional items to apparel. Brands can ensure consistency in their messaging while adapting their designs to different products, thus maximizing brand exposure. This cohesive branding experience is essential in building brand loyalty and recognition. Using UV DTF transfers effectively boosts the overall impact of a company’s branding strategy.

Versatility and Customization with UV DTF Transfers

One of the standout features of UV DTF technology is its remarkable versatility. Brands can utilize this printing method on a diverse range of materials, including textiles, plastics, and metals. This adaptability allows for unprecedented creativity in product offerings, as companies can explore unique designs without being limited by the material constraints typically associated with traditional printing methods. Consequently, businesses have the freedom to innovate and create customized products that truly reflect their branding vision.

Customization is integral to modern branding strategies, and UV DTF excels in this area. Companies can quickly produce customized items tailored to specific consumer preferences or seasonal trends. This capability fosters a more personalized experience for customers, allowing brands to connect on a deeper level. As consumers increasingly seek personalized products, brands utilizing UV DTF transfers can better position themselves in competitive markets, driving sales and fostering brand loyalty.

Enhancing Marketing Strategies through UV DTF Technology

The emergence of UV DTF transfers has transformed traditional marketing strategies, paving the way for innovative promotional solutions. With its ability to produce high-quality prints quickly, businesses can create eye-catching marketing materials that attract consumer interest. Brands can launch targeted campaigns that emphasize unique aspects of their offerings, ensuring that they resonate with their audience. As consumers are continually bombarded with marketing messages, the stunning visuals enabled by UV DTF become a vital component in capturing attention.

Additionally, the quick turnaround associated with UV DTF printing allows brands to stay ahead of trends and respond rapidly to consumer demand. This agility not only enhances operational efficiency but also improves customer satisfaction. For example, a brand can introduce a limited-edition product line or seasonal collections with ease, maximizing the impact of its marketing campaigns. By leveraging UV DTF technology, businesses can adapt more dynamically and effectively to the ever-changing landscape of consumer preferences.

Sustainability and Eco-Friendly Practices in UV DTF Printing

As brands become more conscious of their environmental footprints, UV DTF transfers stand out as a sustainable printing option. The technology minimizes waste by producing prints on-demand, reducing the need for excess inventory that often ends up discarded. Additionally, advancements in eco-friendly inks contribute to a more sustainable production process, allowing brands to align their operations with modern environmental standards. This commitment to sustainability can enhance a brand’s reputation in the eyes of eco-conscious consumers.

Moreover, adopting sustainable practices not only addresses consumer expectations but also positions a brand as a leader in corporate social responsibility. By incorporating UV DTF printing in their branding strategy, companies can actively communicate their values, appealing to a growing segment of the market that prioritizes eco-friendly products. In doing so, brands can foster loyalty among customers who are increasingly looking for brands that support sustainable practices.

Future Trends: UV DTF and Personalized Marketing Strategies

As we look to the future, the integration of UV DTF transfers into personalized marketing strategies signifies a shift towards more tailored customer experiences. This evolution is driven by consumer desires for unique and individualized products that reflect their preferences. Brands are beginning to see the benefits of using UV DTF technology to create bespoke items that engage customers on a personal level. This customization not only enhances consumer loyalty but also aligns with the broader trend of personalized marketing.

The ability to quickly produce small batches of customized products with UV DTF technology enables brands to experiment and innovate in their offerings continually. As companies embrace this technology, they are able to gather customer feedback and adapt their strategies accordingly, leading to even more effective branding efforts. Therefore, as UV DTF continues to develop, it will undoubtedly play an integral role in shaping the future of branding and marketing in a highly personalized marketplace.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers (Direct to Film) utilize ultraviolet curing technology to produce vibrant, durable prints directly onto various substrates. This process involves printing designs onto a special film, which is then cured using UV light, allowing for high-resolution, detailed prints that can adapt to different materials like textiles and plastics.

How can UV DTF transfers enhance branding strategy?

UV DTF transfers can significantly enhance branding strategies by delivering sharp, vibrant prints that improve a brand’s visual identity. With capabilities to produce eye-catching designs on multiple surfaces, brands can create distinct merchandise and promotional products that resonate with their target audience.

What advantages do UV DTF transfers offer for sustainable printing?

UV DTF transfers are advantageous for sustainable printing as they reduce waste associated with excess inventory. By using eco-friendly inks and cutting down on the need for large print runs, brands can align their operations with sustainable practices while still delivering high-quality, custom products.

Why are UV DTF transfers preferred for custom branding solutions?

Brands prefer UV DTF transfers for custom branding solutions due to their material versatility and quick turnaround times. This technology enables businesses to respond rapidly to market trends with custom designs on a wide range of surfaces, making it ideal for limited edition products and timely promotions.

Can UV DTF transfers be used on different materials?

Yes, UV DTF transfers are exceptionally versatile and can be applied to various materials, including textiles, plastics, wood, and metals. This adaptability allows brands to explore creative options for their promotional products, apparel, and packaging.

How do UV DTF transfers compare to traditional transfer printing methods?

UV DTF transfers outperform traditional transfer printing methods by offering superior color vibrancy, durability, and the ability to print on a wider range of substrates. Additionally, the quick curing process and reduced waste associated with UV DTF technology make it a more efficient and eco-friendly choice for brands.

| Key Point | Description |

|---|---|

| UV DTF Technology Overview | Utilizes ultraviolet curing for vibrant and durable prints on various substrates. |

| Color Vibrancy and Detail | Produces high-resolution designs with striking colors enhancing brand perception. |

| Material Versatility | Adapts to print on multiple surfaces, ideal for diverse promotional products. |

| Quick Turnaround | Responds swiftly to market trends and customer demands, improving efficiency. |

| Sustainability Considerations | Reduces waste and promotes eco-friendly practices with sustainable inks. |

| Transformative Case Studies | Brands using UV DTF see increased engagement and sales through unique designs. |

| Future Directions | Shifting towards personalized marketing with unique branding solutions using UV DTF. |

Summary

UV DTF transfers are revolutionizing branding strategies by offering innovative solutions that enhance product visibility and consumer engagement. This advanced technology allows brands to produce vibrant and high-quality prints on a variety of materials, ensuring flexibility and adaptability in marketing approaches. The impressive color accuracy, coupled with the ability to customize designs quickly, makes UV DTF a preferred choice for companies aiming to stand out in a competitive marketplace. As brands increasingly focus on sustainability, UV DTF also aligns with eco-friendly practices, reducing waste while delivering exceptional products. Embracing UV DTF transfers not only positions brands at the forefront of modern marketing but also caters to the growing consumer demand for personalized experiences, ultimately leading to a successful and dynamic branding strategy.