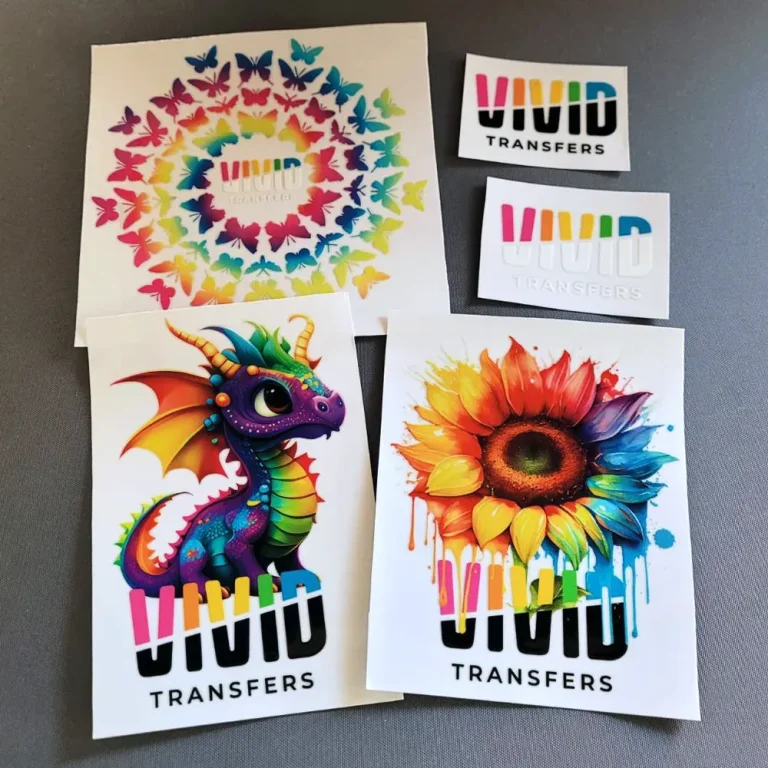

In the realm of customized printing, **UV DTF transfers** are emerging as a revolutionary choice for designers and businesses alike. This innovative printing method combines the efficiency of direct to film transfers with the vibrancy of UV transfer technology, allowing for the creation of eye-catching designs that stand out on various surfaces. From custom apparel to promotional merchandise, UV DTF printing provides unparalleled quality and durability, making it a preferred option for those seeking to transform their creative concepts into reality. As the demand for unique and personalized products continues to grow, understanding the intricacies of UV DTF transfers can position you at the forefront of this dynamic market. Join us as we explore the benefits, processes, and best practices associated with this cutting-edge printing technique.

Custom printing solutions have taken a leap forward with innovative techniques like UV DTF printing, which involves direct to film transfers for stunning results. This modern approach to printing leverages ultraviolet light to cure vibrant inks right onto a specialized film, offering designers a streamlined way to bring their visions to life. The process boasts versatility, allowing for application on diverse materials such as textiles, metals, and glass, catering to a wide range of creative endeavors. With advancements in UV transfer technology, creators can expect exceptional quality and longevity, ensuring their designs remain striking even after prolonged use. Embracing these contemporary methods can truly enhance your repertoire in design transformation and product personalization.

The Versatility of UV DTF Transfers

UV DTF transfers are incredibly versatile, making them suitable for a wide array of applications in the custom printing industry. From clothing and accessories to promotional items and interior decor, the ability to apply vibrant designs to various substrates is unmatched. This flexibility allows businesses to diversify their product offerings, ensuring they can meet the differing tastes and needs of their customers. The adaptability of UV DTF also extends to the types of materials used; whether it is fiberglass, leather, or even wood, this printing technology can accurately reproduce designs with impressive precision.

Another aspect of versatility is the capability to produce both small and large batch orders with ease. This means that whether you are looking to create a handful of custom shirts for an event or run a full production line of promotional merchandise, UV DTF transfers accommodate both. Additionally, the technology allows for intricate designs to be realized with high-quality output, ensuring that even the most detailed graphics are rendered beautifully. This combination of adaptability in materials and design complexity makes UV DTF an essential tool for businesses aiming to stand out in a competitive market.

Understanding the UV DTF Printing Process

The UV DTF printing process is an intricate yet straightforward method that opens doors for creative expression. It begins with the meticulous creation of a design, which can be crafted using graphic design software like Adobe Illustrator. Designers are encouraged to use high-resolution graphics to ensure that every minute detail is captured in the final print. Once the design is finalized, the UV DTF film is loaded into the specialized printer, which uses UV inks that dry quickly and offer stunning brightness. This phase is crucial as the quality of the initial print significantly impacts the final product.

After the printing process, the film must undergo a curing phase where UV light solidifies the ink. This part of the process ensures that the design not only adheres well but also possesses durability against everyday wear and tear. Applying adhesive powder while the ink is still wet is the next critical step, as this guarantees the bond between the film and the substrate during transfer. Following this, the film is positioned onto the intended surface and pressed under heat, completing the transfer. Each stage plays a pivotal role in delivering high-quality, long-lasting products, showcasing the effectiveness of UV transfer technology.

Key Benefits of Using UV DTF Transfers

One of the standout benefits of UV DTF transfers is their unparalleled durability. Unlike other printing methods, UV DTF infuses designs directly into the substrate, providing resistance against fading, scratching, and washing. This ensures that the customized products maintain their quality over time, promoting customer satisfaction and repeat business. Additionally, the eco-friendliness of UV inks, which emit fewer volatile organic compounds, makes UV DTF a more sustainable choice for modern printing needs. Businesses that prioritize environmental responsibility can appeal to a growing market segment seeking green alternatives.

Moreover, the vivid color output achievable with UV DTF transfers is another significant advantage. This printing technique utilizes inks that can produce strikingly bright and detailed images, allowing brands to create standout products that captivate customers. The versatility in material compatibility further enhances the benefits, as businesses can branch out into various products—from promotional items to custom apparel—without compromising on quality. As such, UV DTF transfers not only drive creative freedom but also align closely with commercial objectives in today’s fast-paced market.

Recent Innovations in UV DTF Technology

The UV DTF printing landscape is continually evolving, thanks to a range of recent innovations that enhance both performance and output quality. Recent developments have introduced advanced UV DTF printers capable of faster printing speeds, significantly reducing turnaround times for both small-scale and large-scale orders. With improved color calibration technologies, these printers offer even greater accuracy and depth in color reproduction, transforming how businesses approach their design processes. This advancement is particularly beneficial for companies that require high-volume output without sacrificing detail or vibrancy.

Additionally, progress in adhesive technology is revolutionizing the UV DTF transfer process. New formulations offer improved bonding properties, enhancing the durability of transfers on various substrates. These innovations not only empower designers by expanding the creative realm of product possibilities but also provide practical solutions to long-standing challenges within the printing industry. As these cutting-edge technologies continue to emerge, businesses are encouraged to stay informed, adapting to maintain a competitive edge in the dynamic world of custom printing.

Transform Your Brand with UV DTF Transfers

Incorporating UV DTF transfers into your branding strategy can significantly enhance your product offerings. This modern printing technique allows brands to showcase their identity visually through vibrant, durable designs that resonate with consumers. By utilizing custom prints, businesses can create unique merchandise that effectively communicates their message, leading to improved brand recognition and customer loyalty. A well-executed UV DTF design not only reflects the quality of your products but also elevates the overall customer experience.

The ability to deliver personalized products has never been more important in a competitive market. With UV DTF technology, businesses can respond to customer demands for customization, helping them stand out in a crowded marketplace. Whether it’s through personalized apparel, branded promotional items, or unique gifts, UV DTF transfers provide the flexibility necessary to cater to diverse consumer needs. By embracing this innovative technology, brands can take an important step towards not just improving their product lines, but also solidifying their place in their respective industries.

Exploring Future Trends in UV DTF Printing

As UV DTF printing technology continues to develop, we can expect to see emerging trends that will shape its future landscape. One significant trend is the increasing integration of automation within the printing process. Automated printing solutions can improve efficiency and reduce labor costs, allowing businesses to scale their operations while maintaining high-quality standards. Additionally, advancements in AI and machine learning are anticipated to enhance design capabilities further, enabling more sophisticated and dynamic artwork creation for UV DTF transfers.

Another future trend is the shift towards more sustainable printing practices. As awareness grows around environmental impacts, the demand for eco-friendly solutions will drive innovation in UV inks and films, focusing on biodegradable or recyclable materials. Companies that adopt these sustainable practices not only improve their environmental footprint but also gain favor with consumers who prioritize green initiatives. As these trends take shape, staying adaptable and informed will be crucial for businesses looking to thrive in the evolving UV DTF landscape.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers, or UV Direct to Film transfers, are an innovative printing technique that uses ultraviolet light to cure inks onto a special film. The process involves printing a design, curing the ink with UV light, applying an adhesive, and then using heat to transfer the design onto various surfaces, such as textiles and metals. This method produces vibrant, durable designs ideal for custom printing.

What materials can I use for UV DTF printing?

UV DTF printing is highly versatile and can be applied to a wide range of materials. This includes textiles for custom apparel, hard surfaces like wood and metal, as well as glass items. The flexibility of UV transfer technology allows designers to create unique products across multiple substrates.

What are the advantages of using UV DTF transfers over traditional printing methods?

One of the main advantages of UV DTF transfers is their ability to produce high-quality, vibrant images that are resistant to fading, scratching, and washing. Unlike traditional printing methods, UV DTF offers better durability, versatility, and a more eco-friendly approach with reduced volatile organic compounds (VOCs) in inks. This makes it a preferred choice for businesses looking to create long-lasting custom designs.

How do I ensure the quality of my UV DTF prints?

To ensure the quality of your UV DTF prints, start by using high-resolution images and vector graphics during the design process. Proper printer configuration is crucial; ensure your UV DTF printer settings are optimized for the film and ink being used. Additionally, pay careful attention during the curing and transfer processes to maintain adherence and finish quality.

Can I use UV DTF transfers for small scale custom printing?

Yes, UV DTF transfers are an excellent option for small scale custom printing. With advancements in UV transfer technology making it more accessible, small businesses can benefit from lower setup costs and produce high-quality outputs without the need for large production runs. This makes it easy for designers and entrepreneurs to create unique, customized products on a budget.

What recent innovations have improved UV DTF transfer technology?

Recent innovations in UV DTF transfer technology include enhanced printers that offer faster print speeds and improved color accuracy. Additionally, advancements in adhesive formulations have increased the durability and versatility of transfers. These developments allow users to achieve better results while maintaining efficiency and quality in their custom printing projects.

| Step | Description |

|---|---|

| 1. Design Creation | Create a high-resolution design using graphic software like Adobe Photoshop or Illustrator. |

| 2. Print on Film | Load UV DTF film into the printer and print using UV inks for quality images. |

| 3. Curing the Ink | Cure the printed film using UV light to solidify the ink for durability. |

| 4. Applying Adhesive | Sprinkle adhesive powder onto the wet design and heat to activate bonding. |

| 5. Transfer Process | Position the cured film on the substrate and use a heat press to transfer. |

| 6. Peeling and Finishing | Allow cooling and peel away the film to reveal the final vibrant design. |

Summary

UV DTF transfers are a revolutionary method in the realm of customized printing, delivering unmatched versatility and exceptional durability. This innovative transfer technique combines modern digital printing with the vibrant quality of UV inks, allowing designers to create striking graphics on a wide array of materials. By mastering the UV DTF transfer process, anyone from seasoned designers to enthusiasts can unlock a plethora of creative possibilities, producing high-quality items suited for both personal and commercial use. As advancements in this technology continue to emerge, adopting UV DTF transfers ensures that you remain at the forefront of the printing industry, equipped to deliver top-notch designs that stand the test of time.