UV DTF transfers are reshaping the landscape of graphic printing with their remarkable capacity to deliver high-quality graphics. This innovative printing method combines the efficiency of direct-to-film techniques with the curing power of ultraviolet light, resulting in vibrant and durable images that stand out in any context. One of the key benefits of UV printing is its ability to produce striking colors and fine details, making it ideal for various applications such as apparel, signage, and promotional materials. Additionally, the durability of UV prints ensures that graphics remain intact under heavy use, promising longevity and excellent value for businesses. As industries increasingly prioritize eco-friendly printing solutions, UV DTF transfers not only meet quality expectations but also support sustainability with low VOC emissions.

The landscape of contemporary printing has witnessed significant advancements, particularly through the lens of UV Direct-to-Film (DTF) transfers. This cutting-edge technology merges traditional printing methods with ultraviolet curing, enabling the production of exceptional graphics with unparalleled fidelity. Businesses now can leverage this versatile printing technology to create items ranging from high-quality apparel to sophisticated promotional products, distinguishing their brand in an increasingly competitive market. One of the notable benefits of using UV printing is its robust durability; these prints can withstand various environmental challenges while maintaining their striking visual appeal. Moreover, with a focus on eco-friendly practices, the shift towards UV DTF transfers represents a conscious choice for sustainable business operations.

The Versatility of UV DTF Transfers

UV DTF transfers are celebrated for their exceptional versatility. This printing method can effectively be employed on a diverse array of materials, including fabrics like cotton, polyester, and blends, as well as various plastics such as PVC and PET. This broad adaptability opens the door for businesses to print on a wide range of products—from apparel to promotional items—catering to varied market demands. Moreover, the capacity to work with metals further expands the possibilities, allowing for the creation of unique signage and branded metal merchandise.

In addition to offering varied surfaces for printing, UV DTF technology allows for creative expression across multiple industries. This flexibility is advantageous for businesses looking to diversify their product lines. For example, a company can seamlessly transition from designing ornate T-shirts to producing intricate bags without altering the printing process significantly. Such versatility not only meets consumer expectations but also helps businesses stay competitive and innovative.

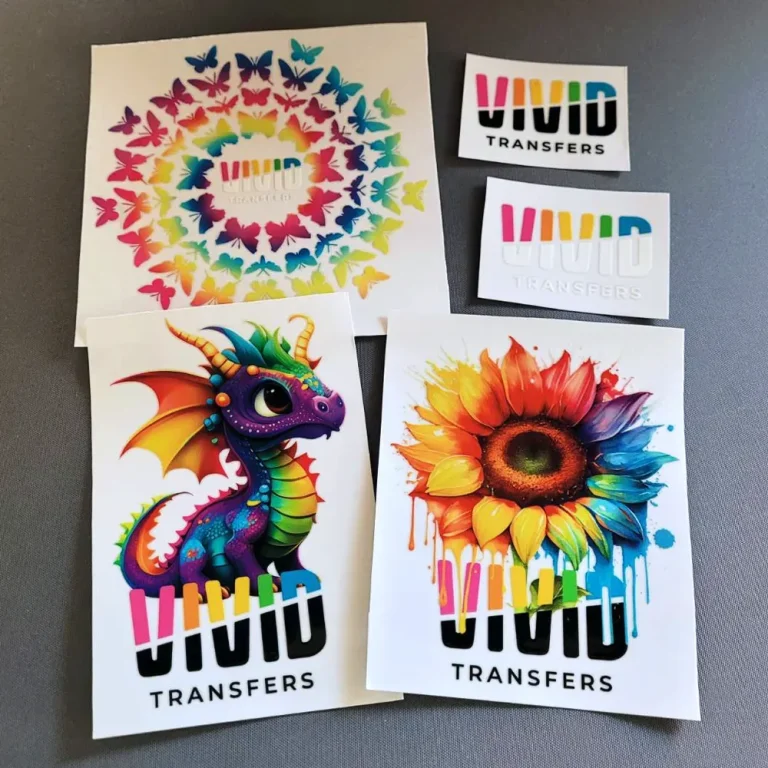

High-Quality Graphics with UV DTF Printing

One of the standout features of UV DTF transfers is their ability to produce high-quality graphics that boast bright colors and fine details. The UV curing process ensures that inks adhere perfectly, resulting in prints that are remarkably vivid and crisp. This aspect is crucial for businesses aiming to capture customer attention with intricate designs and vibrant hues, especially in branding and promotional contexts. A high-resolution graphic produced through UV DTF printing can significantly impact a consumer’s purchasing decision, making it an essential factor for companies aiming to stand out.

Furthermore, the print quality achieved with UV DTF technology is often unmatched, leading to an enhanced brand image for businesses. A commitment to quality can elevate a company’s reputation, encouraging repeat purchases and customer loyalty. In an environment inundated with choices, exceptional graphics can be a defining element that differentiates a product from competitors. Consequently, investing in UV DTF printing can yield substantial returns in terms of customer engagement and brand recognition.

The Durability of UV DTF Prints

The durability of UV DTF prints is a significant selling point for businesses, particularly those whose products undergo frequent handling or exposure to the elements. UV-cured inks create a resilient bond with substrates, making prints resistant to fading, scratching, and washing. This resilience is especially advantageous for items like sportswear or outdoor promotional materials frequently exposed to various stressors. By investing in UV DTF transfers, businesses ensure their products maintain their appearance, providing long-lasting value to customers.

Moreover, the durability of UV DTF prints contributes to reducing overall costs for businesses. When prints last longer, companies save on the costs associated with reprinting or replacing items that wear out quickly. This aspect can lead to increased customer satisfaction, as consumers appreciate high-quality products that withstand the test of time. Therefore, adopting UV DTF printing not only enhances product presentation but also improves the bottom line through reduced production cycles.

Streamlining Production with UV DTF Transfers

The efficiency brought about by UV DTF transfers is a major benefit for businesses aiming to streamline their production processes. Unlike traditional DTF methods, UV DTF printing eliminates the need for duplicated curing phases, allowing for a speedy turnaround time on orders. This speed and efficiency are critical in a market increasingly driven by rapid consumer demand and fast-paced trends. Companies leveraging UV DTF technology can meet tight deadlines, enabling them to respond quickly to market challenges without sacrificing quality.

In addition, the increased productivity facilitated by UV DTF technology allows businesses to take on more substantial projects and expand their client base. With the ability to process larger volumes of prints in shorter time frames, companies can maximize their operational capabilities. This expansion creates more opportunities for revenue generation while enhancing brand reputation as a reliable and efficient supplier in the graphic printing industry.

Eco-Friendly Aspects of UV DTF Transfers

In today’s climate-conscious market, the eco-friendly benefits of UV DTF transfers significantly enhance their appeal. Many UV inks are formulated with lower levels of volatile organic compounds (VOCs), making them a safer choice for the environment compared to traditional solvent-based inks. By choosing UV DTF printing, businesses can minimize their ecological footprint and contribute to sustainable printing practices, which can play a pivotal role in brand image and customer loyalty.

Additionally, companies that adopt eco-friendly printing technologies are often viewed more favorably by consumers who prioritize sustainability. This eco-conscious approach can serve as a unique selling proposition, attracting a more environmentally aware customer base. As consumers increasingly seek out brands that align with their values, eco-friendly UV DTF printing positions businesses to improve not only their market position but also to play a part in promoting responsible printing solutions.

Recent Innovations in UV DTF Technology

The UV DTF printing landscape is experiencing dynamic advancements that further enhance the technology’s market appeal. Recent innovations include sophisticated software integration that optimizes ink consumption and elevates print quality. These developments are making UV DTF printers more accessible to smaller businesses, thus broadening the potential user base. As technology continues to evolve, the efficiency and quality of UV DTF printing will only improve, empowering businesses of all sizes to adopt this cutting-edge method.

In addition to technological advancements, growing market demand underscores the importance of UV DTF transfers in the graphic printing industry. Analysis shows a positive trend in adoption rates as more companies recognize the multifaceted benefits of employing UV DTF solutions. As industries continue to innovate, case studies showcasing successful implementation of UV DTF printing highlight its practical applications, motivating other businesses to invest in this transformative technology for their own branding or promotional needs.

Frequently Asked Questions

What are the main benefits of using UV DTF transfers for high-quality graphics?

UV DTF transfers provide several benefits, including exceptional print quality with vibrant colors, enhanced durability against fading and scratching, and versatility across various materials such as fabrics, plastics, and metals. Additionally, they support eco-friendly printing practices by using lower volatile organic compounds (VOCs), making them a sustainable choice for businesses.

How does the durability of UV DTF prints compare to other printing methods?

The durability of UV DTF prints is significantly superior compared to traditional printing methods. UV-cured inks are resistant to fading, scratching, and washing, ensuring that printed items maintain their vibrant appearance over time. This durability makes UV DTF transfers ideal for high-wear products like sportswear and outdoor promotional materials.

Can UV DTF transfers be used on a variety of materials?

Yes, UV DTF transfers offer exceptional versatility and can be applied to a wide range of materials, including fabrics, plastics, and metal surfaces. This adaptability allows businesses to utilize UV DTF printing for various products such as apparel, accessories, signage, and promotional items, catering to diverse market needs.

Why is UV DTF printing considered an eco-friendly printing option?

UV DTF printing is considered eco-friendly primarily because the inks used typically have lower volatile organic compounds (VOCs) compared to solvent-based alternatives. This makes UV DTF a sustainable choice for environmental-conscious businesses looking to reduce their carbon footprint while producing high-quality graphics.

How does UV DTF technology improve production efficiency for businesses?

UV DTF technology enhances production efficiency by reducing the curing phases required in traditional DTF methods. This results in faster turnaround times and increased productivity, enabling businesses to meet tight deadlines and adapt quickly to market demands, which is crucial in today’s fast-paced environment.

What recent developments are taking place in UV DTF transfer technology?

Recent developments in UV DTF transfer technology include advances in printer software that optimize ink usage and improve print quality. Additionally, there has been significant market growth, with more businesses recognizing the benefits of UV DTF transfers, leading to increased adoption of this versatile and high-quality printing method.

| Key Benefits of UV DTF Transfers | |

|---|---|

| Versatility | Can be applied to various materials (fabrics, plastics, metal), making it adaptable for multiple products and markets. |

| High-Quality Print | Exceptional print quality with vibrant colors and fine detail perfect for branding and intricate designs. |

| Durability | UV-cured inks are resistant to fading, scratching, and washing, making prints long-lasting for high-use items. |

| Reduced Production Time | Streamlined processes result in faster production and increased productivity. |

| Eco-Friendly Options | Lower VOC emissions compared to traditional methods align with sustainable practices. |

Summary

UV DTF transfers are transforming the graphic printing landscape with their ability to deliver high-quality, vibrant prints that are both durable and versatile. This state-of-the-art technology not only enhances the printing process through faster turnarounds and eco-friendly options but also appeals to a wide range of industries. As businesses continue to adopt UV DTF transfers, they benefit from lower production costs, longer-lasting products, and the capacity to meet diverse market demands. With this innovative approach to printing, companies can effectively capture their audience’s attention while promoting sustainable practices.