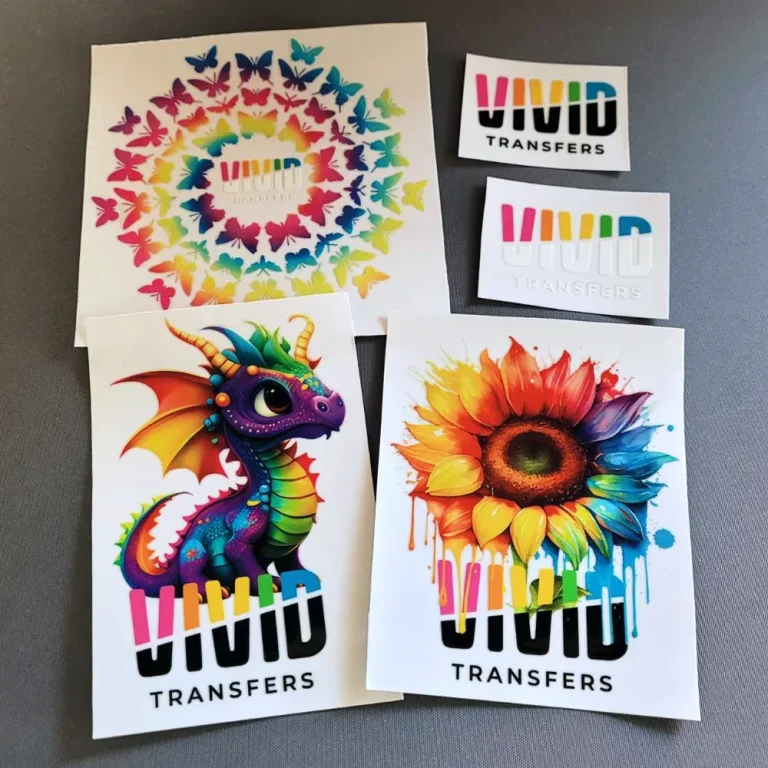

UV DTF transfers have emerged as a groundbreaking innovation in the printing industry, capturing the attention of artists and entrepreneurs alike. Combining the efficiency of Direct to Film printing with advanced UV printing technology, these transfers allow for vibrant and intricate designs to be applied to a variety of surfaces. As more businesses embrace custom apparel printing, the versatility of UV DTF transfers is reshaping market dynamics and offering creative possibilities never seen before. Notably, the eufyMake UV Printer E1 stands out for its user-friendly design and affordability, catering to both hobbyists and small business owners. As the demand for high-quality, customizable printing solutions continues to grow, UV DTF transfers represent not just a trend, but the future of expressive and innovative printing solutions.

Exploring the world of UV DTF transfers unveils a fascinating array of printing techniques and technologies that are redefining the landscape of ink application. Direct to Film technology combined with ultraviolet curing opens up new avenues for artists looking to produce personalized apparel and merchandise with ease and precision. With the introduction of cutting-edge machinery like the eufyMake UV Printer E1, creators can harness the power of UV printing to deliver stunning visuals and textures. Companies like Sam’s DTF Transfers are leading the charge, showcasing the impact of this innovative printing method on custom apparel printing. Collectively, these advancements point towards an exciting future in which UV DTF technology continues to thrive, offering endless possibilities for customization and creativity.

Understanding the Mechanics of UV DTF Transfers

UV Direct to Film (DTF) transfers represent a revolutionary advancement in printing technology, combining rapid curing processes with vibrant color capabilities. At the heart of this technology is the UV curing method, which utilizes ultraviolet light to instantly bond and dry the ink on film, ensuring that colors remain vivid and details sharp. This efficiency is especially beneficial for businesses that require high-volume production without sacrificing quality. Furthermore, the versatility of UV DTF allows for applications across various materials, from textiles to hard surfaces, making it an essential tool for artists and designers.

The core mechanics of UV DTF transfers involve several intricate steps, starting from the design stage, where images are created digitally. Once ready, these designs are printed onto a special film using advanced printers equipped with UV technology. This film can then be transferred onto virtually any surface, expanding the customization possibilities for product makers. As the demand for personalized items continues to rise, understanding these mechanics can help businesses leverage UV DTF transfers to stand out in a competitive market.

Revolutionizing Custom Apparel with UV DTF

The advent of UV DTF printing has significantly transformed the custom apparel industry, offering unparalleled opportunities for creativity and design. Unlike traditional methods, UV DTF allows for intricate designs that are not only vibrant but are also durable and resistant to wear and tear. This innovation has prompted businesses to explore new apparel lines featuring detailed graphics, textures, and multi-dimensional prints, catering to a growing consumer base that craves unique and standout pieces.

Companies such as Sam’s DTF Transfers have embraced UV DTF technology, leveraging its capabilities to enhance the quality and appearance of their custom clothing offerings. Their focus on in-house production assures customers of the authenticity and excellence of their products. This commitment to quality, combined with the limitless potential of DTF technology, positions them as leaders in the custom apparel market, a trend that is likely to continue expanding as consumers seek personalized items that reflect their individual styles.

The Game-Changing eufyMake UV Printer E1

Among the innovative tools emerging in the UV printing landscape, the eufyMake UV Printer E1 has captured attention for its user-friendly design and affordability. This printer is particularly well-suited for small business owners and hobbyists interested in producing high-quality UV DTF transfers. With its ability to print directly onto films ready for transfer, the eufyMake UV Printer E1 simplifies the process of creating custom merchandise, enabling users to produce vibrant designs quickly and efficiently.

The eufyMake UV Printer E1 is not just a cost-effective option; it represents a significant shift towards making advanced UV printing technology accessible to a broader audience. By allowing creators to produce stunning prints at a fraction of the cost associated with larger industrial printers, it empowers small businesses to innovate and experiment with unique designs that can elevate their brand. As more users adopt such technology, the potential for creative expression in the printing market will continue to expand.

Exploring 3D-Texture UV Printers

The introduction of 3D-texture UV printers has taken printing capabilities to new heights, enabling businesses to produce products with unprecedented levels of detail and texture. This innovative technology allows for layered designs that provide a tactile experience, appealing to consumers looking for unique products that stand out in the marketplace. Such advancements not only enhance the aesthetic value of printed items but also open new avenues for creative expression across various industries, including fashion and product customization.

With features like a Rotary Printing Attachment, 3D-texture UV printers can accommodate a wide range of applications, from elaborately designed toys to customized apparel with 3D effects. As these printers become more readily available, companies can capitalize on consumer desires for distinctive, textured designs, pushing the boundaries of traditional printing methods. This revolution in 3D printing not only enriches the standard of printed goods but also encourages innovation among creators seeking to expand their product offerings.

Sam’s DTF Transfers: Elevating Customization Standards

As the custom apparel sector continues to expand, Sam’s DTF Transfers is at the forefront of this boom, exemplifying the strengths of DTF technology in delivering high-quality products. Their commitment to in-house production ensures that they maintain rigorous quality control standards, resulting in transfers that customers can rely on for vibrant colors and durability. This focus on excellence is essential in a market flooded with options, allowing them to build a loyal customer base that appreciates quality craftsmanship.

Incorporating advanced UV DTF technology into their production process, Sam’s DTF Transfers has set a benchmark for personalization in clothing. The ability to adapt designs for various materials and clothing types means customers can expect a wide range of styles and customizations suited to their preferences. This flexibility not only strengthens their market position but also highlights the increasing acceptance and demand for innovative printing methods in the apparel industry.

The Future of UV DTF Transfers in Printing

The trajectory of UV DTF transfers indicates a promising future for the printing industry, driven by continuous technological advancements and consumer appetite for customization. Innovations like the eufyMake UV Printer E1 and the emergence of 3D-texture UV printers are redefining what is possible in printing, enabling standardization of high-quality outputs across various applications. The capability to print on diverse materials with complex designs not only enhances product offerings but also empowers entrepreneurs in their creative ventures.

As more businesses and individuals harness the unique benefits of UV DTF printing, the landscape of both commercial and artisanal printing will continue to evolve. The rise of customizable products, coupled with improved printing technology, suggests that this sector will diversify and flourish. As we step into this future, the potential for UV DTF transfers to reshape the traditional printing industry grows, fostering an environment filled with innovation and creativity.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers utilize UV printing technology to print vibrant designs on film that is instantly cured using UV light. This allows for high-quality images to be transferred onto various substrates, making UV DTF a versatile choice for custom apparel printing.

What advantages do UV DTF transfers offer over traditional printing methods?

UV DTF transfers provide faster curing times and superior detail compared to traditional printing methods. With the ability to print on multiple surfaces, including fabric and metal, this technology is particularly advantageous for businesses looking to innovate their custom apparel printing.

How does the eufyMake UV Printer E1 enhance UV DTF transfers?

The eufyMake UV Printer E1 enhances UV DTF transfers by offering user-friendly features and affordability. This printer allows creators to print directly onto transfer films that can be applied to various materials, streamlining the custom apparel printing process.

What role do companies like Sam’s DTF Transfers play in the UV DTF transfer market?

Companies like Sam’s DTF Transfers play a crucial role in the UV DTF transfer market by providing high-quality, premium in-house production services. Their focus on exceptional quality in custom apparel printing helps set industry standards and fosters consumer trust.

What are some creative applications of UV DTF printing technology?

UV DTF printing technology is used for a variety of creative applications, ranging from custom apparel to promotional merchandise, decorative items, and personalized gifts. The flexibility of the technology allows for unique designs and textures, elevating overall product appeal.

What should consumers look for when choosing a UV DTF printer?

When selecting a UV DTF printer, consumers should consider factors such as printer technology, ease of use, and compatibility with various materials. Models like the eufyMake UV Printer E1 are noteworthy due to their affordability and versatile printing capabilities ideal for custom apparel projects.

| Category | Details |

|---|---|

| Introduction | Technological advancements lead to UV DTF transfers revolutionizing custom image printing. |

| Definition | Combines Direct to Film printing with UV curing technology for vibrant, durable prints. |

| Innovative Printers | eufyMake UV Printer E1: Affordable with versatile applications for custom merchandise. |

| 3D-Texture Printers | First of its kind, enhances printing capabilities and allows for texturing on surfaces. |

| Market Impact | Companies like Sam’s DTF Transfers show growth in custom apparel due to DTF methods. |

| Expansion Opportunities | New printing methods are creating opportunities in promotional merchandise and fashion. |

| Future Outlook | As technology advances, UV DTF transfers will enhance entrepreneurial opportunities in printing. |

Summary

UV DTF transfers are revolutionizing the printing industry by offering innovative solutions for customization and efficiency. As advancements in technology continue to unfold, these transfers will enable artists and businesses to create vibrant, intricate designs across a multitude of surfaces. By utilizing cutting-edge printers like the eufyMake UV Printer E1 and the pioneering 3D-texture printer, businesses can cater to diverse consumer demands while promoting sustainability. The future of UV DTF transfers appears bright, transforming the landscape of both commercial and artistic printing, fostering innovation, and providing endless possibilities for creative expression.