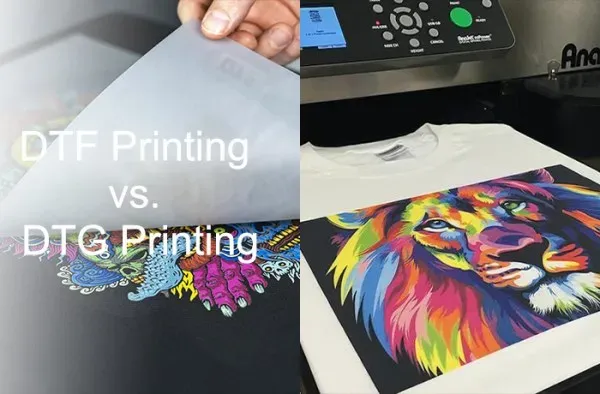

In the ever-evolving landscape of custom apparel printing, understanding the nuances of **UV DTF Transfers vs. DTG Printing** is crucial for making informed decisions. These two technologies offer distinctive methods for bringing designs to life, catering to diverse needs in the marketplace. While DTG printing shines with its vibrant colors and intricate details on fabric, UV DTF printing offers versatility, allowing for application on a myriad of substrates. The choice between these methods can significantly affect the final print quality, cost efficiency, and sustainability of your projects. In this article, we’ll delve into a comprehensive comparison of UV DTF and DTG printing, examining their technologies, strengths, and environmental implications.

When considering advancements in the realm of fabric and material printing, one might encounter the terms **Direct-to-Film (DTF)** transfers and **Direct-to-Garment (DTG)** printing frequently. These alternatives represent the best of current printing technology, appealing to businesses engaged in the growing trend of custom clothing and promotional items. In this discussion, we will analyze the effectiveness of **DTF transfers** and **DTG technology** in achieving high-quality prints and their application across various fabric types. By exploring the specific advantages of each method, such as production speed and print durability, customers can better determine which approach aligns with their sustainability goals and design aspirations. Ultimately, understanding these options will empower you to make informed choices for your custom printing projects.

Understanding UV DTF Transfers: A Modern Printing Technique

UV DTF Transfers leverage cutting-edge technology that employs ultraviolet light to cure pigments on a transfer film. This innovative approach not only allows for vibrant designs but also extends its application beyond textile printing to various hard substrates like metal and wood. The ability to print on multiple materials makes UV DTF particularly appealing to businesses seeking versatility in custom apparel and product offerings.

One of the key features of UV DTF is its adaptability; it seamlessly combines aesthetic appeal with durability. The cured inks are designed to withstand both scratch and UV damage, making them suitable for products that experience outdoor use or rough handling. As sustainability and diverse applications become paramount in printing technology, UV DTF stands at the forefront, meeting the needs of modern consumers.

DTG Printing: Harnessing Digital Technology for Apparel

Direct-to-Garment (DTG) printing is a sophisticated method that allows for the direct application of ink onto fabric using advanced inkjet technology. This approach is particularly advantageous for creating designs with intricate details and vibrant colors, appealing to businesses focused on high-quality custom apparel printing. DTG excels in its ability to handle complex graphics with subtle gradations, which is a crucial factor for brands emphasizing unique, artistic expressions.

While DTG printing offers numerous advantages in terms of print quality, it requires specialized equipment and processes, including pre-treatment of fabrics for optimal results. This factor can lead to higher initial costs, particularly when starting operations. However, the economic efficiency of DTG shines in smaller runs where personalization and immediate production are of utmost importance, making it a favored choice in the burgeoning custom apparel market.

Print Quality Comparison: Evaluating UV DTF and DTG

When it comes to evaluating print quality, the differences between UV DTF and DTG are notable. DTG printing is renowned for its superior capability to produce vibrant colors and intricate details directly onto fabrics. This detail-oriented process is especially beneficial for cotton and cotton blends, allowing for a soft feel and excellent color representation, crucial for fashion-forward brands.

In contrast, while UV DTF transfers also produce quality prints, some users notice that they may not achieve the same brightness or detailed finish as DTG, particularly on lighter fabrics. However, UV DTF compensates with its resilience and versatility, ensuring good quality across diverse materials. Businesses must consider their target audience’s expectations regarding print quality when choosing between these methods.

Cost Efficiency in Printing: DTG vs. UV DTF

Understanding cost efficiency is crucial for businesses contemplating DTG and UV DTF printing technologies. DTG often incurs higher upfront expenses due to the need for specific machinery and pretreatment solutions. However, as the production volume increases, the per-unit cost can decrease subsequently, making it economically viable for custom prints and smaller orders.

On the other hand, UV DTF printing may offer a more economical solution for larger production runs, especially when incorporating various types of substrates. Businesses that aim to produce diverse products at scale may find UV DTF to be a more cost-effective choice in the long run. Balancing initial investment and expected production volume is essential in the decision-making process.

Environmental Impact: Sustainability in Printing Technologies

As environmental awareness grows among consumers, the printing industry is adapting with a focus on sustainability. DTG printing utilizes water-based inks, which are significantly less harmful than solvent-based alternatives, thus appealing to eco-conscious consumers and brands. This approach aligns with the ongoing initiative for sustainable printing methods, allowing businesses to showcase their commitment to the environment.

Similarly, advancements in UV DTF inks have paved the way for more eco-friendly options, with manufacturers increasingly prioritizing sustainability in their formulations. While UV inks provide benefits in durability and application range, opting for greener alternatives helps brands enhance their market appeal. Both printing technologies present viable paths for organizations aiming to reduce their ecological footprint.

Current Trends in Custom Apparel Printing: UV DTF vs. DTG

The custom apparel printing landscape is rapidly evolving, with innovations in both UV DTF and DTG technologies. The rising trend towards personalized products has catalyzed a demand for these printing techniques. UV DTF is capturing attention due to its flexibility across materials, allowing manufacturers to explore new markets and product lines.

Conversely, DTG printing continues to thrive, particularly for businesses that specialize in vibrant, custom graphics. As consumer preferences shift towards unique and customized items, both methods are adapting to meet these market trends, making it essential for businesses to stay informed and agile in their production strategies.

Frequently Asked Questions

What are the main differences between UV DTF transfers and DTG printing?

The main differences between UV DTF transfers and DTG printing include the printing technology used, print quality, durability, and material compatibility. UV DTF uses ultraviolet light to cure inks on transfer films, allowing application on diverse substrates, while DTG applies ink directly onto fabrics, especially cotton. DTG is known for vibrant colors and intricate details, whereas UV DTF offers greater durability and versatility for various materials.

Which method provides better print quality: UV DTF transfers or DTG printing?

DTG printing typically offers superior print quality due to its ability to reproduce vibrant colors and intricate designs with high detail on fabrics. UV DTF printing provides good print quality as well, but it may not achieve the same level of color richness and detail on textile substrates, especially lighter fabrics.

How do UV DTF transfers and DTG printing compare in terms of durability?

UV DTF transfers are generally more durable and resistant to scratching and fading, making them an excellent choice for outdoor apparel and products exposed to wear. In contrast, DTG printing can fade over time, but with proper care, it offers decent wash durability. The choice between the two methods depends on the specific use case and expected longevity of the printed product.

Are UV DTF transfers or DTG printing more cost-effective for custom apparel printing?

The cost-effectiveness of UV DTF transfers versus DTG printing depends on production scale. DTG printing may have higher initial setup costs but lower per-unit costs for larger batches, making it cost-effective for small orders. On the other hand, UV DTF is more economical for large production runs and diverse materials, providing flexibility in custom apparel printing.

Which printing method is more environmentally friendly: UV DTF transfers or DTG printing?

DTG printing is generally considered more environmentally friendly due to its use of water-based inks, which are less harmful than solvent-based inks. However, advancements in UV inks are leading to more eco-friendly options in UV DTF printing as well. It’s crucial for businesses to consider sustainability in their printing methods to enhance their brand reputation.

What market trends are influencing the choice between UV DTF transfers and DTG printing?

Market trends are leaning towards customization, driving demand for both UV DTF transfers and DTG printing. UV DTF’s adaptability to a variety of materials attracts manufacturers looking for versatility, whereas DTG remains popular in the t-shirt printing sector for its ability to deliver vibrant custom graphics. Staying updated with these trends is essential for businesses to maintain competitiveness in custom apparel printing.

| Criteria | UV DTF Transfers | DTG Printing |

|---|---|---|

| Technology Overview | Uses UV light to cure ink on transfer film. Can be applied to fabrics and hard surfaces. | Applies ink directly onto fabric using inkjet technology, ideal for cotton and blends. |

| Quality | Good quality, however, may lack vibrancy on lighter fabrics. | Exceptional detail and vibrant colors, perfect for intricate designs. |

| Durability | More resistant to scratching and fading, suitable for outdoor use. | Can fade over time, but good wash durability with proper care. |

| Cost | Generally lower costs for larger runs; more economical for diverse projects. | Higher initial setup costs, but cost-effective for small batches due to low per-unit costs. |

| Production Speed | Faster production on larger runs. | Longer processing time, especially with pre-treatment requirements. |

| Market Trends | Increased demand for versatility across various materials. | Popular among t-shirt businesses for delivering custom graphics. |

| Environmental Considerations | UV inks becoming more eco-friendly. | Utilizes water-based inks, less harmful to the environment. |

Summary

In the exploration of UV DTF Transfers vs. DTG Printing, it’s evident that both methodologies present unique strengths tailored for specific applications. UV DTF Transfers shine with their versatility and durability, making them suitable for a variety of substrates, while DTG Printing excels in delivering vibrant colors and detailed designs for textiles. Understanding the nuances of UV DTF Transfers vs. DTG Printing is critical in making an informed choice that meets your printing goals, whether for personal projects or business endeavors.