UV DTF Transfers represent a cutting-edge advancement in printing technology that is reshaping the landscape for businesses seeking high-quality image reproduction. Unlike traditional transfer methods such as screen printing and heat transfer, UV DTF utilizes ultraviolet light to cure inks, resulting in vibrant colors and exceptional detailing. This innovative approach enables versatile applications across various surfaces, including fabric, plastic, and metal, while simplifying the production process and enhancing efficiency. As companies increasingly focus on rapid turnaround and eco-friendly options, UV DTF stands out as a frontrunner, offering solutions that align with modern sustainability goals. Understanding the benefits and limitations of UV DTF transfers compared to traditional ink printing methods can help businesses make informed choices for their branding and product needs.

When exploring the realm of advanced printing techniques, UV DTF Transfers, also known as Direct to Film Transfers utilizing ultraviolet curing, emerge as a revolutionary option in the printing industry. This method distinguishes itself from established practices such as heat transfer and traditional screen printing, offering unique advantages in terms of color vibrancy and material compatibility. With the ability to cater to a wide range of surfaces, UV DTF provides businesses with unparalleled versatility, ensuring that intricate designs can be achieved with ease. As the demand for efficient and sustainable printing grows, understanding the nuances of these cutting-edge techniques becomes essential for companies looking to elevate their product offerings. By considering alternative terms like direct-to-film and UV printing, businesses can better navigate the landscape of modern printing technologies.

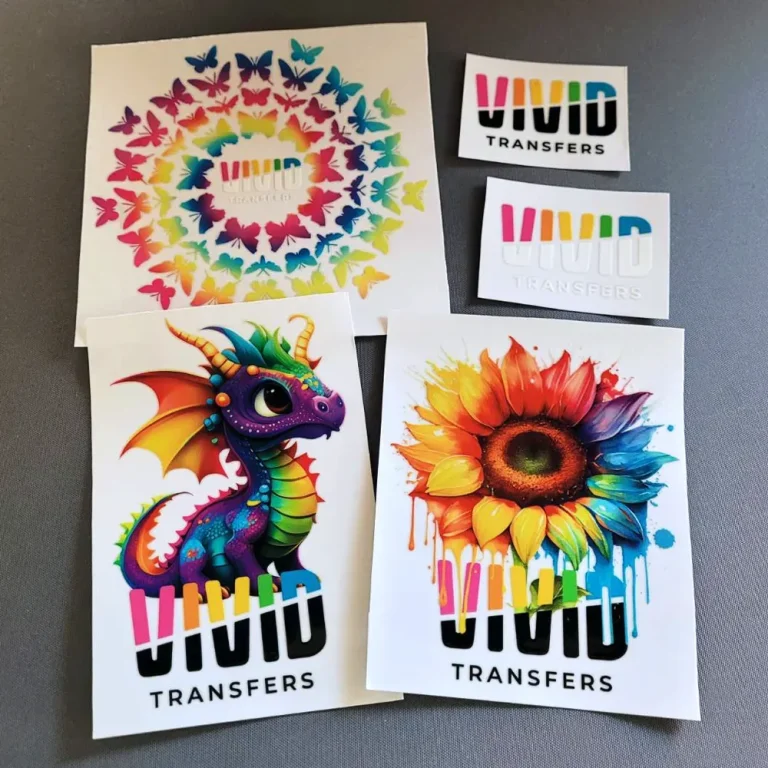

Exploring UV DTF Transfers: A Revolutionary Printing Method

UV DTF Transfers stand out as a cutting-edge printing technology that harnesses ultraviolet light to cure ink directly onto a film. This technique offers exceptional color saturation and precision, enabling printers to create intricate designs that are both vivid and durable. Unlike traditional transfer methods, UV DTF allows for printing on a diverse range of surfaces, from textiles to rigid materials like metal and plastic. This flexibility makes it an appealing option for businesses looking to diversify their product lines without needing multiple types of equipment.

The process begins with high-quality ink being applied to a special film, where UV light cures the ink almost instantly. This expedited drying time significantly reduces production cycles, allowing companies to meet demanding deadlines without compromising on quality. Furthermore, UV DTF is noted for its environmentally friendly characteristics, as many inks used are low in VOCs, thus presenting a sustainable alternative to some traditional methods.

Traditional Transfer Methods: A Time-Tested Approach

Traditional transfer methods, particularly screen printing and heat transfer, have been foundational to the printing industry for decades. Screen printing, known for its capacity to produce strikingly bold colors and durable prints, leverages a stenciling process that limits the type of details but excels in producing vibrant designs. On the other hand, heat transfer method involves printing an image onto special transfer paper and then using heat to transfer it onto a substrate, which can deliver high-detail results.

However, the limitations of traditional methods become apparent when discussing versatility and efficiency. Screen printing often involves extended setup times and is generally less efficient for small runs due to its substantial preparation requirements. While these techniques are time-honored and reliable, they may not withstand the competitive pressures faced by businesses that demand rapid turnaround and high variability in design.

Speed and Efficiency in UV DTF Transfers

One of the most significant advantages of UV DTF transfers lies in their remarkable speed. The absence of a drying phase, which is common in traditional transfer techniques, accelerates the production timeline. This can be particularly advantageous for businesses operating within tight deadlines or experiencing seasonal spikes in demand. With UV DTF, the entire printing process can be completed in just a fraction of the time, allowing companies to take on more orders and boost their revenues.

Additionally, the swift production cycle is complemented by the high-quality output that UV DTF technology delivers. The ability to maintain print quality at high speeds ensures that even intricate designs are rendered without any compromise, from complex gradients to fine lines. In contrast, traditional methods may struggle under pressure, often leading to delays and subpar results, particularly when ramping up production for larger orders.

Challenges of UV DTF Transfers: Understanding the Investment

While UV DTF transfers present numerous advantages, they are not without their challenges. The primary concern for potential adopters is the initial investment required for the necessary machinery. High-quality UV DTF printers can be expensive, which may pose a barrier for small to medium-sized businesses. This upfront cost, combined with the need for UV-specific inks, can create hesitancy among companies that operate under tight budget constraints.

Moreover, proficiency in operating UV DTF machines may necessitate specialized knowledge. Print staff must be trained not only to handle the equipment but also to optimize print settings for quality outputs. This added layer of complexity can create a steeper learning curve compared to more familiar traditional methods, ultimately affecting the transition for businesses aiming to upgrade their printing technology.

Advantages of Traditional Printing Techniques in Bulk Production

Despite the rise of modern technologies like UV DTF, traditional printing methods such as screen printing continue to hold significant advantages, particularly in bulk production scenarios. When producing large quantities of items, the cost per unit decreases dramatically with screen printing. This efficiency makes it a favored choice for businesses aiming to produce thousands of items, as it can minimize operational costs while delivering consistent quality across all pieces.

Furthermore, the reliability of traditional methods cannot be understated. Screen printing is known for its durability, often producing prints that withstand significant wear and tear. This established method has garnered trust and reassurance from businesses that prioritize proven durability in their product designs. While there are limitations in color diversity and detail, the value it brings in consistent bulk production remains unmatched in many scenarios.

The Decision-Making Process: Choosing the Right Printing Method

Choosing between UV DTF transfers and traditional methods ultimately depends on the specific needs of a business. Companies looking for vibrant, detailed designs and the capability to print on diverse substrates will likely benefit from the adaptability and quality that UV DTF offers. Its rapid production times also meet the growing demands of quick turnaround, making it an excellent choice in today’s fast-paced market.

Conversely, businesses focused on high-volume production with budget constraints may find traditional methods, especially screen printing, to be more aligned with their operational goals. Understanding the nuances and requirements of each technology will empower businesses to select a printing method that not only fits their budget but also aligns with their production capabilities and design aspirations.

Frequently Asked Questions

What are UV DTF Transfers and how do they differ from traditional transfer methods?

UV DTF Transfers, or UV Direct to Film Transfers, use ultraviolet light to cure the ink, allowing for vibrant colors and detailed images on various substrates. Unlike traditional transfer methods such as screen printing and heat transfer, UV DTF is more versatile, accommodating textiles, plastics, and metals, thus expanding design options.

Why should I choose UV DTF Transfers over screen printing or heat transfer?

Choosing UV DTF Transfers offers several advantages over traditional methods like screen printing and heat transfer. UV DTF provides faster production times due to no drying phase, exceptional detail in high-resolution images, and compatibility with a wide range of materials, making it ideal for intricate designs and diverse products.

Are UV DTF Transfers cost-effective compared to traditional transfer methods?

While UV DTF Transfers may entail a higher initial investment, especially for the machinery, they can be cost-effective in the long term due to their efficiency and ability to produce high-quality prints quickly. For businesses engaged in small to medium runs, the savings in time and versatility can outweigh the initial costs compared to traditional methods.

What are the environmental benefits of using UV DTF Transfers over traditional screen printing?

UV DTF Transfers are often more eco-friendly than traditional screen printing methods, as modern UV inks typically contain fewer volatile organic compounds (VOCs), leading to a lesser environmental impact. This makes UV DTF a preferable option for businesses looking to minimize their ecological footprint.

Can UV DTF Transfers produce high-resolution images like traditional printing technologies?

Yes, UV DTF Transfers excel in delivering high-resolution images and a broad color spectrum that can rival traditional printing technologies. Unlike conventional methods that may require multiple screens for detailed designs, UV DTF allows for intricate graphics without the same limitations.

What challenges might I face when adopting UV DTF Transfers compared to traditional methods?

Adopting UV DTF Transfers can present challenges such as the need for specialized training to operate the machinery effectively and the upfront costs associated with purchasing UV DTF equipment. Conversely, traditional methods like screen printing often require extensive setup but have a more established and familiar process for many businesses.

| Key Point | UV DTF Transfers | Traditional Transfer Methods |

|---|---|---|

| Technology Overview | Uses UV light for curing, allows for vibrant colors and details, versatile across substrates. | Includes screen printing and heat transfer; known for durability and bold colors but less versatile. |

| Advantages | Speedy production, high-quality detail, compatibility with various surfaces, eco-friendly. | Cost-effective for bulk production, well-established reliability. |

| Challenges | High initial investment costs, requires specialized knowledge. | Limited color range & detail, longer setup times. |

Summary

In the world of printing, UV DTF Transfers represent a modern solution for creating vibrant and detailed images on a variety of surfaces. This technology stands out due to its ability to quickly cure ink using ultraviolet light, resulting in superior quality and efficiency compared to traditional methods. While UV DTF transfers may involve higher upfront costs and a learning curve for operators, their numerous benefits—including versatility, ecological advantages, and exquisite detail—make them an excellent choice for businesses looking to enhance their product offerings. In contrast, traditional methods like screen printing continue to be invaluable for large-scale productions due to their cost-effectiveness and reliability. Ultimately, the choice between UV DTF Transfers and traditional printing methods should be based on specific business needs, including budget constraints, volume requirements, and desired print quality.