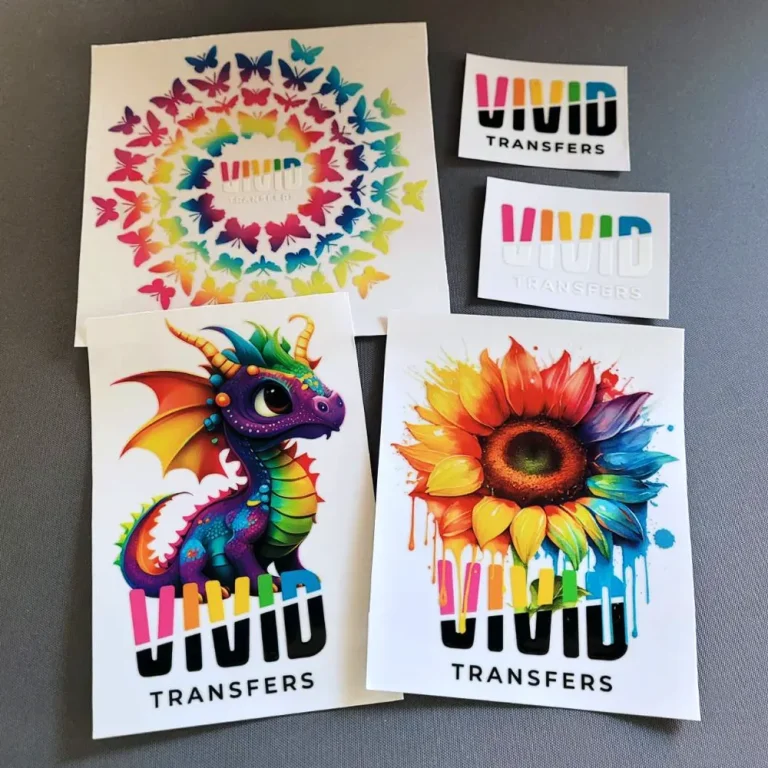

UV DTF Transfers are revolutionizing the printing industry by offering an innovative alternative to traditional printing methods like screen printing and heat transfer vinyl. This cutting-edge technology employs ultraviolet light to cure ink directly onto a film, which is then transferred to various surfaces including fabrics, metals, and plastics. With the ability to produce vibrant colors and intricate designs, UV DTF printing provides a level of detail and durability that traditional methods often struggle to achieve. Businesses are rapidly embracing UV DTF due to its cost-effectiveness, especially for custom printing projects and smaller runs that require quick turnaround times. In this guide, we will explore the benefits of UV DTF Transfers and help you choose the best printing method for your specific needs.

When discussing advanced printing techniques, **UV Direct-to-Film (DTF) printing** emerges as a standout option in comparison to the more conventional methods such as **screen printing** and **heat transfer vinyl (HTV)**. Through the utilization of ultraviolet light technology, this modern approach not only enhances print quality but also optimizes efficiency by seamlessly transferring images onto diverse materials. As a result, UV DTF offers unparalleled versatility for customizing products, making it a preferred choice among businesses seeking to maximize their creativity and cater to varied customer demands. In this article, we will delve deeper into how UV DTF compares to traditional approaches and the unique advantages it brings to the table.

The Versatility of UV DTF Transfers

One of the most significant advantages of **UV DTF transfers** is their remarkable versatility. Unlike traditional printing methods like screen printing and heat transfer vinyl, which often have limitations regarding the materials they can effectively print on, UV DTF printing excels across a diverse range of substrates. This capability allows businesses to offer an extensive array of customized products—from apparel and accessories to promotional items and signage. By utilizing UV DTF technology, companies can cater to the unique demands of various industries, tapping into markets that require specialized items.

Moreover, the ability to print on unconventional surfaces—such as metals and plastics—positions UV DTF as a leading choice among printers looking to diversify their offerings. Since clients increasingly seek personalized products, the versatility of UV DTF printing not only streamlines production but also enhances creativity, enabling designers to implement intricate and colorful graphics without the constraints faced in traditional methods.

Comparative Durability of Printing Methods

Durability is another critical factor where **UV DTF transfers** outshine traditional printing techniques. When ink is cured using ultraviolet light, the result is a high-quality finish that is exceptionally resistant to environmental factors such as sunlight and moisture. This quality contrasts with screen printing and heat transfer vinyl, where fading and peeling can occur over time, particularly when exposed to harsh conditions. By opting for UV DTF, businesses can ensure that their prints remain vibrant and intact for prolonged periods, thus elevating customer satisfaction and reducing the need for reprints.

Furthermore, the advancements in UV ink formulations contribute significantly to the resilience of these prints. Unlike conventional inks that may degrade or lose adhesion, UV inks boast enhanced scratch resistance and color fidelity. This durability makes UV DTF a smart investment for companies committed to maintaining high standards for their products, ensuring that the visual appeal and quality are preserved even in demanding environments.

Cost-Effectiveness: A Key Factor in Choosing Printing Methods

When evaluating the feasibility of **UV DTF transfers** against traditional methods like screen printing and heat transfer vinyl, cost-effectiveness plays a pivotal role. For small to medium print runs, UV DTF often presents a more economical solution. The avoidance of multiple screens and lengthy setup times associated with screen printing enables businesses to save both time and money, making it particularly beneficial for custom orders that require quick turnaround.

In addition, while the initial equipment investment for UV DTF might be higher than that of basic screen printing setups, the efficiency and speed gained through UV DTF technology can lead to substantial savings in labor costs and production time over the long term. Companies with fluctuating demand can greatly benefit from the adaptability of UV DTF, as it allows them to respond to market needs without incurring additional costs associated with traditional print setups.

Quality and Detail: Achieving Superior Print Results

In the realm of print quality, **UV DTF printing** is renowned for delivering exceptional detail and clarity. This printing process is adept at capturing intricate designs, fine lines, and delicate gradients—elements that traditional methods like screen printing may struggle to reproduce accurately. For artists, creators, and brands looking to showcase their designs with precision, UV DTF offers the ideal solution to bring their visions to life.

Additionally, the consistent quality of UV DTF transfers, which remain vibrant and details intact even after multiple washes or exposure to external elements, sets it apart from screen printing and heat transfer vinyl. This reliability in print quality not only enhances the aesthetic appeal of the products but also reinforces the brand’s commitment to excellence, making UV DTF a preferred choice for quality-conscious businesses.

Emerging Trends in UV DTF Printing

The landscape of printing is witnessing a significant shift, with **UV DTF printing** at the forefront of this revolution. As businesses embrace technological advancements, the demand for high-quality, efficient printing solutions continues to soar. Emerging trends reveal that industries such as fashion, promotional products, and signage are increasingly turning to UV DTF printing, driven by its ability to produce vibrant and long-lasting prints that cater to contemporary consumer desires for personalization and uniqueness.

Current market insights suggest that as the technology surrounding UV DTF printing evolves, costs are becoming more accessible, allowing even small businesses and startups to incorporate it into their operations. Consequently, this trend indicates a growing preference for UV DTF among entrepreneurs seeking an edge in a competitive marketplace, highlighting its role as a game changer in the printing industry.

Making the Right Choice: Factors to Consider in Printing

When determining whether to adopt **UV DTF transfers** or remain with traditional printing methods, several factors are crucial for businesses to consider. Cost efficiency, material compatibility, and advertising needs must align with the chosen technology. Companies engaged in high-volume, simple design productions might still find traditional methods, such as screen printing, beneficial due to their economies of scale. However, for those aiming to produce detailed, customized items or variations in lower quantities, UV DTF emerges as the superior choice.

Additionally, understanding client demands and aesthetic preferences plays a vital role in making the right printing choice. With UV DTF’s outputs consistently exhibiting exceptional detail and durability, businesses can confidently invest in this innovative technology, ensuring they meet client expectations while maintaining creative freedom and operational efficiency.

Frequently Asked Questions

What are UV DTF Transfers and how do they differ from traditional printing methods?

UV DTF Transfers, or UV Direct-to-Film transfers, utilize ultraviolet light to cure inks printed on a film that can be transferred to various surfaces. Unlike traditional printing methods, such as screen printing, UV DTF allows for a wider range of materials to be printed on with vibrant colors and high durability.

Why should I choose UV DTF printing over screen printing?

Choosing UV DTF printing offers several advantages over screen printing, including faster turnaround times for intricate designs without the need for multiple screens. UV DTF produces high-quality prints with detailed images and can be applied to an array of substrates, making it a versatile choice for custom printing.

Is UV DTF suitable for small print runs compared to traditional heat transfer vinyl?

Yes, UV DTF is particularly advantageous for small print runs as it eliminates the need for extensive setup procedures, common in heat transfer vinyl (HTV) methods. This efficiency makes UV DTF a cost-effective solution for businesses that require quick and varied customization.

How does the quality of UV DTF transfers compare to traditional printing techniques?

UV DTF transfers typically offer superior quality and detail compared to traditional printing techniques like screen printing. The ability to print fine details and gradients effectively makes UV DTF ideal for intricate designs that require high precision.

What are the advantages of using UV DTF transfers in custom printing projects?

The advantages of using UV DTF transfers in custom printing projects include vibrant color reproduction, excellent durability against fading, and versatility across various materials. These qualities make UV DTF a popular choice for personalized products in fashion and advertising.

Are there any limitations to using UV DTF printing compared to traditional methods?

While UV DTF printing has many benefits, potential limitations include higher upfront costs for equipment and compatibility issues with certain fabrics. It’s essential to assess your printing needs and specific materials to determine if UV DTF is the right choice for your project.

| Key Point | UV DTF Transfers | Traditional Methods |

|---|---|---|

| Overview | Utilizes UV light to cure inks directly onto film for versatile applications. | Includes methods like screen printing and heat transfer vinyl (HTV), which have established processes. |

| Quality | Offers vibrant colors and superior detail, ideal for intricate designs. | May struggle with details, especially in multi-color designs due to reliance on stencils. |

| Efficiency | Fast production times, suitable for smaller or customized runs. | Can be time-consuming due to setup processes, especially with multiple colors. |

| Cost | More cost-effective for small batches, avoiding multiple setups. | Lower cost-per-unit for large print runs, but less flexibility in designs. |

| Applications | Capable of printing on a variety of materials including fabric, metal, and plastic. | Commonly associated with bulk orders and simpler designs. |

Summary

UV DTF Transfers have revolutionized the printing industry by providing a modern alternative to traditional printing methods. Unlike conventional techniques, UV DTF transfers utilize cutting-edge ultraviolet light technology to create vibrant and durable prints on a wide variety of substrates. This innovative process allows for exceptional detail and faster production times, making it an ideal choice for businesses looking to enhance customization and efficiency. As market trends shift towards high-quality, quick-turnaround printing, understanding the advantages of UV DTF transfers can significantly impact your operational success.