In the ever-evolving landscape of product customization, **UV DTF transfers** have emerged as a revolutionary printing method that outshines many traditional printing techniques. Unlike screen printing or vinyl printing, which often struggle with detailed designs and color vibrancy, UV DTF transfers leverage advanced technology to deliver high-resolution images with remarkable durability. This innovative approach to printing ensures that your designs not only look captivating but also withstand the test of time, making them ideal for a variety of surfaces, from fabrics to plastics. As businesses seek efficient and versatile solutions, comparing UV DTF transfers to other methods like direct-to-garment printing and traditional screen printing becomes essential. In this guide, we’ll delve into the pros and cons of UV DTF technology, positioning it as a game-changer in the printing industry.

Known as UV direct-to-film printing, **UV DTF transfers** offer an advanced alternative to conventional methods such as screen printing and direct-to-garment techniques. This printing process utilizes ultraviolet light to cure designs onto transparent film, which is then transferred onto an array of materials. As businesses increasingly demand adaptable and high-quality printing solutions, exploring the benefits of UV DTF transfers becomes crucial. By examining how this technology measures up against traditional printing options, such as vinyl printing, we uncover its potential to transform product customization. Additionally, this modern approach addresses the limitations often associated with older printing methods, inviting creatives to rethink their production strategies.

Understanding UV DTF Transfers: An Innovative Solution

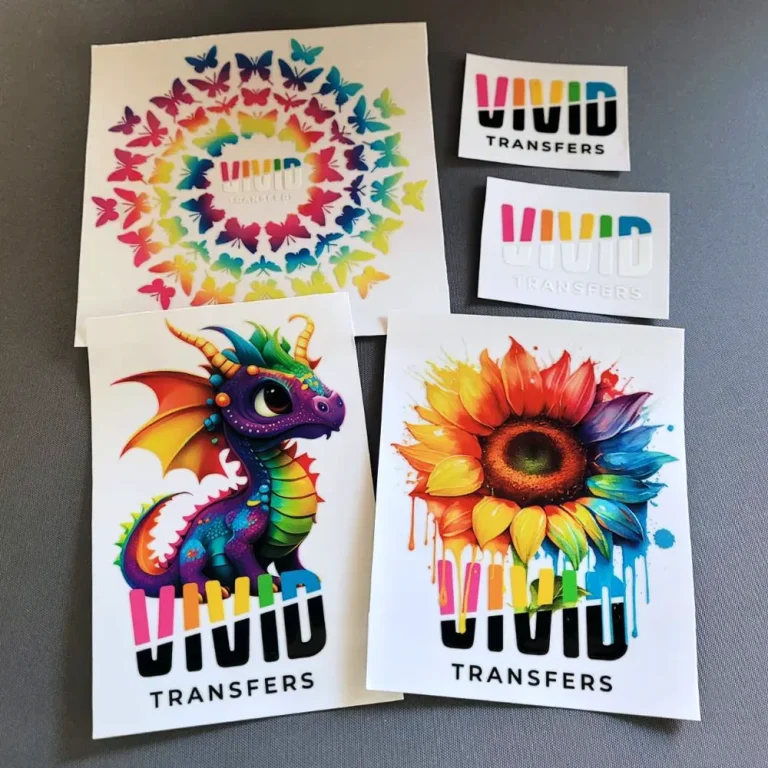

UV DTF transfers, or Ultraviolet Direct-to-Film transfers, represent a paradigm shift in the world of printing technologies. Distinguished by their use of specialized films and UV light curing, this technique allows for high-quality prints on a variety of substrates. The process begins with printing an image onto a film, which is then cured using UV light to create a durable graphic that can be transferred onto surfaces such as fabrics, metals, and plastics. This versatility makes UV DTF ideal for businesses aiming to produce colorful and intricate designs across diverse products.

One of the standout features of UV DTF transfers is their exceptional durability. Unlike traditional printing methods, such as screen printing or direct-to-garment printing, which sometimes lead to fading or wear over time, UV DTF prints are more resistant to environmental factors. The inks are designed to withstand exposure to elements, making them perfect for outdoor applications as well. Furthermore, the rapid curing process significantly shortens production times, enabling businesses to meet tight deadlines without compromising on quality.

Pros and Cons of UV DTF Transfers

The advantages of UV DTF transfers are quite compelling, especially when compared to traditional methods like screen printing and vinyl printing. One major benefit is the technology’s ability to produce vibrant, high-resolution images that remain intact even after prolonged use. Additionally, UV DTF transfers offer greater flexibility in terms of the types of materials that can be printed on, spanning a wide range from cotton to hard surfaces. However, businesses should note the initial investment required to acquire the necessary UV DTF printing equipment, which can be a barrier for smaller operations.

On the downside, UV DTF printing also comes with challenges that users need to navigate. The requirement for technical expertise in operating the machinery may deter individuals unfamiliar with modern printing technologies. Moreover, while the upfront costs can be high, the long-term savings on materials and setup time could justify the expense for businesses looking to scale. Balancing these pros and cons is crucial for determining whether UV DTF transfers are the right fit for a company’s unique printing needs.

Comparing UV DTF Transfers to Screen Printing

Screen printing has long been a go-to method for companies looking to produce high volumes of prints with vibrant colors. However, the advent of UV DTF transfers presents a modern alternative that offers its own set of advantages and disadvantages. For instance, screen printing typically excels in producing simple designs on a large scale at a lower cost per unit; however, it is less efficient for smaller batches or intricate graphics, which can be demanding in terms of setup and labor.

In contrast, UV DTF transfers allow for detailed designs with minimal setup time, making them perfect for smaller orders or personalized products. This technology also enables quicker turnaround times compared to screen printing’s labor-intensive processes. While screen printing is still celebrated for its color vibrancy and durability, UV DTF’s adaptability and speed showcase why it’s gaining traction in today’s customizable market.

The Role of Direct-to-Garment (DTG) Printing

Direct-to-garment (DTG) printing stands as another traditional method that presents unique benefits when juxtaposed with UV DTF transfers. DTG is renowned for its ability to reproduce detailed images and color gradients, making it an excellent choice for designs requiring a high level of detail. Particularly popular in the realm of custom t-shirts, DTG has become the favored option for businesses focusing on smaller orders due to its lower upfront costs and ease of use.

However, the limitations of DTG become apparent when considering production speed and fabric compatibility. UV DTF transfers outshine DTG by offering quicker print speeds and broader compatibility with various materials, including both textiles and rigid surfaces. In scenarios where businesses require rapid production across multiple substrates, UV DTF technology may be the optimal solution for meeting diverse customer demands while maintaining quality.

Evaluating Vinyl Printing Against UV DTF Transfers

Vinyl printing is an established method frequently utilized for signage and simple designs that require quick application. While it offers several benefits, such as durability and an ease of use for straightforward graphics, vinyl printing falls short in terms of color range and complexity when compared to UV DTF transfers. UV DTF can produce multi-colored images with exquisite detail, a feat that is challenging to replicate using vinyl, particularly for elaborate designs.

Furthermore, vinyl prints can be susceptible to cracking or peeling over time, especially when subjected to environmental stress. In contrast, UV DTF prints, being cured with ultraviolet light, offer enhanced resistance to wear and tear. For businesses eager to push creative boundaries while delivering products with longevity, the choice between vinyl printing and UV DTF transfers should favor the latter, given its superior characteristics in today’s competitive printing landscape.

Making Informed Decisions in Printing Technology

When it comes to selecting a printing technology, understanding the strengths and weaknesses of various methods, including UV DTF transfers and traditional approaches, is vital for informed decision-making. The choice should reflect not just the financial implications but also the desired end product and market trends. For businesses that cater to a diverse clientele with varied needs, integrating UV DTF technology could serve as a valuable asset, providing versatility and high-quality output.

In conclusion, as the landscape of printing technology evolves, businesses must consider the unique capabilities of each printing method. While traditional printing methods have their advantages, UV DTF transfers are positioned as a modern choice that meets the demands of today’s market. Making an informed decision regarding printing options involves a thorough understanding of each technique’s capabilities and limitations in relation to company goals and customer expectations.

Frequently Asked Questions

What are the advantages of UV DTF transfers over traditional printing methods?

UV DTF transfers offer several advantages compared to traditional printing methods, including greater versatility as they can be applied to various materials like textiles, plastics, and metals. They also provide superior durability against fading and scratching due to UV curing. Additionally, UV DTF technology enables faster production times, making it ideal for businesses with tight deadlines.

How do UV DTF transfers compare to screen printing in terms of quality?

While screen printing is known for producing vibrant and long-lasting colors, UV DTF transfers also deliver high-quality prints with intricate designs and rich color depth. Unlike screen printing, which can be labor-intensive and less efficient for small runs, UV DTF provides a quicker and more efficient solution for diverse printing needs, making it a strong competitor in the printing industry.

Can UV DTF transfers be used on all fabrics like direct-to-garment printing?

Yes, UV DTF transfers are versatile and can be applied to a wide range of fabrics, unlike direct-to-garment (DTG) printing, which is limited to specific textiles. This includes not only cotton and blends but also synthetic materials, providing businesses with more options for product customization.

What are the limitations of UV DTF transfers compared to traditional printing methods?

One major limitation of UV DTF transfers is the initial equipment cost, which can be high compared to traditional printing methods. Additionally, users may require specialized technical skills to operate and maintain the machines effectively, along with potential software integration challenges. However, these limitations are often outweighed by the benefits provided by UV DTF technology.

How do environmental impacts of UV DTF transfers stack up against traditional vinyl printing?

UV DTF transfers generally have a lower environmental impact than traditional vinyl printing methods as they emit fewer volatile organic compounds (VOCs). Many UV inks are also formulated to be more eco-friendly, making the UV DTF printing technology a more sustainable option in contrast to the solvent-based inks often used in vinyl printing.

What makes UV DTF transfers a better option for businesses than traditional printing technologies?

UV DTF transfers are better for businesses because they combine speed, versatility, and durability, enabling rapid production across multiple substrates while maintaining high-quality output. This combination meets the evolving demands of modern customization, making UV DTF technology an attractive solution compared to traditional printing technologies like screen printing, DTG, and vinyl printing.

| Aspect | UV DTF Transfers | Traditional Printing Methods |

|---|---|---|

| Pros | Versatile application on various materials; Durable against fading and scratches; Fast production; Environmentally friendlier inks. | Cost-effective for bulk orders; Vibrant colors; Good for small batches (DTG); Quick for simple designs (Vinyl). |

| Cons | High initial costs; Requires technical skills; Limited software flexibility. | Labor-intensive for small runs (Screen); Slower production (DTG); Limited designs and durability issues (Vinyl). |

| Ideal Use Cases | Custom products across diverse materials for high durability and quality needs. | Bulk orders with less intricate designs; Small batches with detailed graphics; Rapid applications for simple text or graphics. |

Summary

UV DTF transfers represent a transformative approach to product customization that combines versatility and exceptional durability. This modern printing method, which utilizes UV light to cure inks on various substrates, offers several advantages over traditional techniques including screen printing, direct-to-garment (DTG), and vinyl printing. Notably, UV DTF technology excels in protecting designs from fading and wear, while also catering to a diverse range of materials. As businesses assess their printing options, understanding the distinctive benefits and limitations of UV DTF transfers versus traditional methods can lead to more informed and strategic decisions, ultimately enhancing product quality and customer satisfaction.