UV DTF transfers represent a revolutionary advancement in printing technology, seamlessly merging versatility with high-quality output. Unlike traditional printing methods such as screen printing and direct to garment printing (DTG), UV DTF allows creators to explore a broader array of materials while delivering vibrant and precise designs. This innovation not only enhances print quality but also offers a cost-efficient solution for small production runs without compromising on detail. As businesses navigate the complex landscape of various printing options, understanding the unique benefits of UV DTF transfers becomes essential. In this article, we will delve deeper into how these transfers compare with conventional methods, helping you make informed choices for your printing endeavors.

Often referred to as ultraviolet direct to film printing, UV DTF transfers are quickly gaining traction in the printing industry, celebrated for their superior versatility and efficiency. This technique stands distinct from earlier practices like screen printing and direct-to-garment methods, presenting a modern alternative that caters to diverse material needs. With its impressive print fidelity and resilience, UV DTF not only elevates the aesthetic of printed products but also provides remarkable durability across various surfaces. Businesses are increasingly attracted to this contemporary approach, seeking both quality and speed in their printing projects. In this discussion, we will explore how this innovative method holds its ground against more traditional outputs, emphasizing the strengths and limitations integral to each.

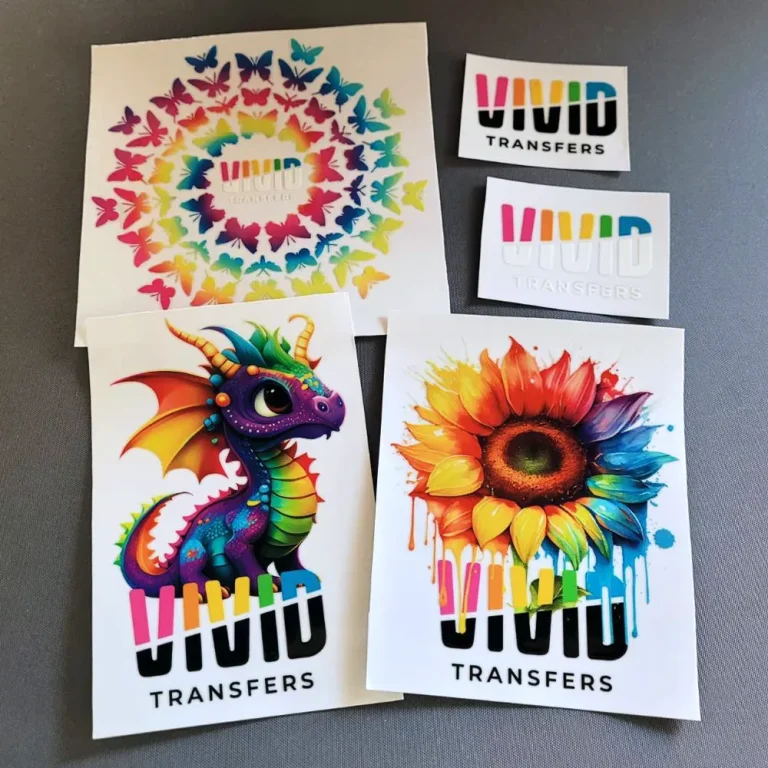

Exploring the Advantages of UV DTF Transfers

UV DTF transfers have emerged as a groundbreaking technology in the printing industry, offering remarkable advantages over traditional methods. One of the most striking features is their exceptional print quality. Unlike screen printing, which can struggle with intricate designs, UV DTF transfers deliver sharp, vibrant images consistently across various substrates. This technology allows for full-color designs while ensuring durability against scratches and fading. Additionally, the versatility of UV DTF enables printing on diverse materials such as plastics, metals, and even wood, catering to a wider array of creative applications.

Moreover, the efficiency of UV DTF transfers is noteworthy. Due to their fast production capabilities, businesses can respond swiftly to on-demand orders, significantly reducing turnaround times. This rapid production cycle adheres to the current market demand for quick fulfillment while maintaining high print quality. Consequently, the technology becomes an appealing choice for small businesses and entrepreneurs looking to innovate without the overhead typically associated with more traditional methods like DTG and screen printing.

Cost Efficiency in Printing: UV DTF vs. Traditional Methods

When it comes to cost efficiency, UV DTF transfers provide a compelling argument for businesses focused on smaller production runs. While the initial investment in UV DTF printers and materials can be higher, the long-term savings associated with reduced setup time and lower material waste cannot be overlooked. Unlike screen printing, which often requires extensive setup processes and may not be economically viable for order sizes smaller than certain thresholds, UV DTF allows for affordability even for limited quantities.

In contrast, traditional methods like screen printing may present lower costs per unit at scale, but they incur higher upfront labor and setup expenses. DTG printing, while beneficial for its detailed prints, tends to have higher ink costs that could deter cost-sensitive businesses from adopting this method for large orders. Thus, while traditional printing methods have their merits, the cost-effective potential of UV DTF transfers for small to mid-sized jobs is a significant factor for many modern print businesses.

Print Quality Comparison: UV DTF Transfers and Traditional Techniques

The print quality offered by UV DTF transfers stands out in comparison to traditional printing techniques like screen printing and direct-to-garment (DTG) printing. UV DTF technology ensures vibrant colors and sharp details, making it ideal for designs that require high fidelity and impact. Unlike screen printing, which can sometimes limit color complexity and detail, UV DTF uses a unique process that embraces intricate designs without sacrificing vibrancy or texture. This capability is paramount in creating memorable products, particularly in markets saturated with visually-driven options.

On the other hand, DTG printing excels at producing colorful images on cotton fabrics, but its efficiency diminishes with intricate designs due to longer processing times. As a result, while screen printing is widely used for straightforward designs and bulk orders, it falls short when it comes to complex color gradations and detailed graphics. This aspect further emphasizes the need for businesses to weigh their print requirements against the capabilities of each method when selecting a printing technique.

The Environmental Impact of UV DTF Transfers

As sustainability remains a major concern across industries, the environmental impact of various printing methods has come under scrutiny. UV DTF transfers utilize eco-friendly materials and water-based inks, significantly reducing the use of harsh chemicals common in other print processes. This environmentally-conscious approach not only appeals to consumers who prioritize sustainable practices but also demonstrates a commitment to reducing waste and pollutants that traditional methods may produce.

In contrast, traditional printing methods like screen printing have often relied on chemical-based inks that can be harmful to the environment. The potential for excess waste and pollution can tarnish a brand’s image, especially among environmentally aware consumers. Therefore, adopting UV DTF technology can help businesses align with green initiatives and promote their ecological efforts, potentially enhancing their market appeal and customer loyalty.

User-Friendliness: Advantages of UV DTF Technology

One of the significant benefits of UV DTF transfers is their user-friendliness. These printers are designed with accessibility in mind, allowing operators with minimal technical skill to produce high-quality prints efficiently. This ease of use encourages small business owners and independent creators to enter the printing market without the need for extensive training or expertise, unlocking new opportunities for creativity and innovation.

In contrast, traditional methods such as screen printing and DTG printing can demand a more comprehensive understanding of the printing process, equipment operation, and troubleshooting. This complexity may deter novice users and limit the demographic able to use these methods effectively. Thus, UV DTF transfers present a more approachable option for those looking to dive into the world of printing, fostering a more inclusive environment for aspiring entrepreneurs.

Recent Innovations in Printing Technology: UV DTF and Beyond

The evolution of printing technology continues to accelerate, with UV DTF transfers gaining notable traction in recent years. These innovations are driven by the need for superior print quality, versatility, and efficiency, especially in an ever-changing marketplace. Recent advancements have led to improved formulations for inks that enhance durability and vibrancy, making UV DTF a go-to choice for quality-conscious print providers.

Additionally, as more businesses express interest in UV DTF transfers, manufacturers are responding with enhanced equipment that streamlines the printing process and integrates new technologies. This ongoing evolution hints at a future where UV DTF printing could reshape consumer expectations and industry standards, challenging traditional techniques like DTG and screen printing, while providing viable solutions adaptable to a wide range of printing needs.

Frequently Asked Questions

What are the main advantages of UV DTF transfers over traditional printing methods?

UV DTF transfers offer several advantages compared to traditional printing methods like screen printing and direct to garment printing. These advantages include superior print quality, versatility across different materials, reduced setup time, and lower costs for smaller production runs. Additionally, UV DTF printing produces vibrant, detailed prints that remain durable against scratches and fading.

How does the print quality of UV DTF transfers compare to screen printing?

The print quality of UV DTF transfers surpasses that of screen printing in terms of detail and color complexity. While screen printing is excellent for high-volume jobs with fewer colors, UV DTF transfers can achieve intricate designs with vibrant colors across various substrates, resulting in a more professional appearance.

Are UV DTF transfers cost-efficient for small businesses?

Yes, UV DTF transfers can be highly cost-efficient for small businesses, particularly for smaller production runs. Although the initial setup might be higher than traditional printing methods, the reduced material waste and quicker turnaround times can lower overall costs, making it a practical option for on-demand printing.

What materials can be printed using UV DTF transfers?

One of the standout features of UV DTF transfers is their versatility. Unlike traditional methods, which are often limited to textiles, UV DTF printing can be applied to a wide range of materials including plastics, metals, wood, and more, making it suitable for various applications from promotional items to custom gifts.

How does production speed of UV DTF transfers compare with direct to garment printing?

UV DTF transfers generally offer faster production speeds than direct to garment printing. While DTG printing requires more time for setup and printing, UV DTF technology allows for quicker completions, making it ideal for businesses needing rapid delivery without compromising on quality.

What is the environmental impact of UV DTF transfers versus traditional printing?

UV DTF transfers are considered more environmentally friendly compared to many traditional printing methods. They often utilize water-based inks and generate less waste, aligning with sustainable practices. This contrasts with some traditional processes, like screen printing, which can rely on harsher chemicals and produce more pollutants.

| Key Point | UV DTF Transfers | Traditional Printing Methods |

|---|---|---|

| Print Quality and Versatility | Produces vibrant, crisp prints; can print on various materials (plastics, metals, wood) and is durable against fading and scratches. | Good for bulk orders but struggles with intricate designs and complex colors; best on cotton fabrics but slower production time for large runs. |

| Cost Efficiency | Higher initial setup costs but cheaper for small runs due to reduced waste and quicker turnarounds. | Lower cost per unit for large orders, but significant setup costs; potentially higher ink costs for DTG printing makes it less efficient for large batches. |

| Production Speed | Quick completion ideal for on-demand needs; fast job turnarounds. | Initial setup for screen printing can slow down production; DTG printing is slower with intricate designs. |

| Environmental Impact | Utilizes water-based inks and fewer harsh chemicals, making it an eco-friendly option. | Traditional methods may involve more waste and pollutants, impacting eco-friendliness negatively. |

| User-Friendliness | Generally easier to operate, making it accessible for small businesses and creators without extensive experience. | Screen printing and DTG require more technical skills, which might deter novice printers. |

Summary

UV DTF transfers represent a pivotal evolution in printing technology, offering unparalleled print quality, versatility, and efficiency. This innovative method excels in producing vibrant and detailed prints on an array of materials, which is a significant advantage over traditional printing methods such as screen printing and direct-to-garment printing. Despite its higher initial setup costs, UV DTF transfers can be more cost-effective for smaller runs due to minimal material waste and fast turnaround times, appealing to businesses focused on efficiency and quality. Moreover, UV DTF’s environmentally friendly approach, utilizing water-based inks and reduced harsh chemicals, aligns with the increasing consumer demand for sustainable practices. In summary, UV DTF transfers not only meet but exceed the expectations of today’s businesses, positioning them as a superior choice for those seeking high-quality results while maintaining a commitment to eco-friendliness.